Piastre d'acciaio resistenti all'usura svolgono un ruolo fondamentale in molte industrie, specialmente in quegli ambienti che richiedono un alto livello di attrito e impatto. NM500 e AR500 sono due piastre d'acciaio resistenti all'usura ampiamente utilizzate, ciascuna con le proprie caratteristiche in termini di durezza, resistenza all'usura, resistenza all'impatto, ecc. Allora qual è la differenza tra loro? Questo articolo esplorerà la differenza tra NM500 e AR500 da diversi punti di vista, e spero che sarà utile a tutti.

Cos'è NM500?

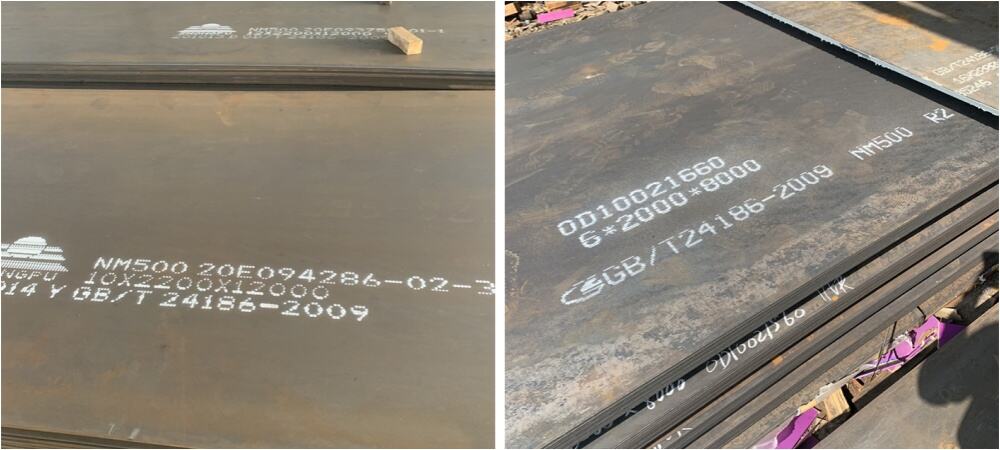

NM500 è una lamiera d'acciaio con alta resistenza all'usura intensa come sua principale caratteristica, di solito con una durezza di 500HB, e può resistere a un'attrizione e usura estremamente elevate. Rispetta determinati standard internazionali, come quelli della Cina GB/T24186-2009, ecc., e ci sono anche certificazioni e standard rilevanti a livello internazionale, come ISO, ASTM, ecc.

Cos'è l'AR500?

AR500 è una lamiera d'acciaio resistente all'usura con alta durezza e resistenza agli impatti. L'"AR" nel suo nome sta per Abrasion Resistant, e il "500" indica la durezza Brinell della lamiera d'acciaio, che è circa 500 HB (Durezza Brinell 500). Ha una resistenza agli impatti e all'usura estremamente elevata. Viene spesso utilizzata in armature protettive, installazioni militari e altre applicazioni ad alto impatto.

Qual è la Differenza tra NM500 e AR500?

Durezza:

Durezza:

NM500: La lamina in acciaio NM500 ha una durezza di 500HB. Nonostante abbia una alta durezza, si comporta bene di fronte a impatti e usura di intensità inferiore. La sua durezza è adatta per ambienti ad alto attrito, specialmente durante il lavoro a lungo termine nei settori minerario, acciaio e altri, che può ridurre efficacemente l'usura dei componenti.

AR500: Ha anch'essa una durezza di 500HB, ma poiché durante il processo di produzione si concentra di più sulla resistenza agli impatti, può mantenere una maggiore tenacia sotto impatti ad alta intensità. Rispetto al NM500, l'AR500 può meglio sopportare carichi di impatto ad alta velocità e forti.

Resistenza all'usura:

Resistenza all'usura:

NM500: Il NM500 ha un'eccellente resistenza all'usura ed è adatto per ambienti con attrito e usura di intensità media, come macchinari minerari, attrezzature edili, ecc. La sua alta durezza può resistere efficacemente all'attrito e all'usura convenzionali.

AR500: La resistenza all'usura dell'AR500 è eccezionalmente elevata tra le lastre di acciaio ad alta durezza e si adatta particolarmente agli ambienti ad alto impatto e ad alto sfregamento. L'AR500 ha una grande durezza e può resistere a un'usura estrema, come l'usura ad alta velocità, l'impatto di sabbia e pietre, ecc. La sua resistenza all'usura è generalmente superiore a quella del NM500 e si adatta a scenari applicativi che richiedono una resistenza all'usura estremamente elevata, come la protezione militare, l'attrezzatura mineraria, ecc.

Resistenza all'impatto:

Resistenza all'impatto:

NM500: Caratterizzato principalmente dalla resistenza all'usura, è adatto per ambienti di lavoro meccanici con carichi pesanti e può resistere a un frizione e usura continue.

AR500: Anche se ha una forte resistenza all'usura, si comporta meglio negli ambienti ad alto impatto e ad alto impatto ad alta velocità, ed è adatto ai campi di protezione e corazza.

Adattabilità Ambientale:

Adattabilità Ambientale:

Entrambi possono adattarsi a condizioni di lavoro severe, ma l'AR500 si comporta in modo più stabile in ambienti a temperature estreme e ad alto impatto. Il NM500 ha una maggiore durata sotto condizioni di frizione e carico a lungo termine.

Prestazioni di lavorazione e modellazione:

Prestazioni di lavorazione e modellazione:

NM500 ha prestazioni di lavorazione relativamente buone ed è adatto per la lavorazione di parti antiscoramento con forme e specifiche complesse. AR500 ha una maggiore durezza, e durante la lavorazione si deve prestare particolare attenzione alla scelta degli strumenti e della tecnologia di lavorazione.

NM500 e AR500, Come scegliere?

Requisiti di applicazione:

Requisiti di applicazione:

In genere, se lo scenario di applicazione richiede un attrito e unusura a lungo termine con impatti leggeri, si consiglia di scegliere NM500. Se lo scenario di applicazione prevede impatti ad alta intensità o persino requisiti antiproiettile, AR500 è una scelta più adatta.

Vincoli di bilancio:

Vincoli di bilancio:

Se il budget è limitato, ma è necessaria una grande resistenza all'usura, NM500 è una scelta economica. Se il budget è sufficiente e sono richieste una forte resistenza agli impatti e all'usura, AR500 potrebbe essere più in linea con le esigenze.

Fornitori:

Fornitori:

Diversi fornitori possono avere differenze in termini di qualità del prodotto, scala di produzione e prezzo. Scegliere un fornitore affidabile è fondamentale.

Anche se NM500 e AR500 hanno una durezza simile, presentano significative differenze di prestazione. NM500 si concentra di più sulla resistenza all'usura ed è adatto per ambienti di usura a carichi elevati, mentre AR500 è migliore nella resistenza agli impatti ed è ampiamente utilizzato in ambiti di protezione, militari e lavorazioni ad alto impatto. Scegliere il materiale giusto richiede una valutazione complessiva di diversi fattori come le situazioni di applicazione specifiche, il budget e i fornitori.

Siamo un produttore professionista di acciaio. Se hai bisogno, puoi contattarci in qualsiasi momento!

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )  info@steelgroups.com

info@steelgroups.com