Bei der Anwendung moderner Industriematerialien, farbbeschichtete Spirale ist mit seiner exzellenten Korrosionsbeständigkeit, vielfältigen Designmöglichkeiten und breiter Verarbeitungskompatibilität zu einem der Kernmaterialien in den Bereichen Bauwesen, Haushaltsgeräte und Verkehr geworden. Als ein Produkt, das Funktionalität und Dekoration perfekt verbindet, erfüllt der farbige beschichtete Bandstahl nicht nur die menschliche Sehnsucht nach Schönheit, sondern bietet auch effiziente und umweltfreundliche Lösungen für die industrielle Fertigung.

Was ist eine farbbeschichtete Spule?

Farbbeschichtete Spirale ist eine speziell behandelte Metallblechrolle. Sein Herstellungsprozess besteht darin, die Oberfläche des Metallträgers mit mehreren Beschichtungsschichten zu überziehen und diese dann bei hohen Temperaturen zu härten, um einen Schutzfilm und einen Dekorationsfilm zu bilden. Der Träger umfasst normalerweise galvanisierte Stahlrollen, kaltgewalzte Stahlrollen oder Aluminiumrollen. Der farbige beschichtete Bandstahl vereint die mechanische Stärke des Metalls mit der Korrosionsbeständigkeit und dem ästhetischen Erscheinungsbild der Beschichtung und ist ein Material, das sowohl funktional als auch dekorativ ist.

Grundlegende Zusammensetzung des farbbeschichteten Bandes :

Die Leistungsfähigkeit des farbbeschichteten Bandes wird durch sein Trägermaterial und das Beschichtungssystem bestimmt.

Trägermaterial:

Das Trägermaterial des farbbeschichteten Bandes ist der Kern, der die Leistung trägt und direkt die Haltbarkeit und Anwendbarkeit des farbbeschichteten Bandes beeinflusst. Die wichtigsten Trägermaterialien umfassen:

Wärmegalvanisiertes Stahlband (GI)

Wärmegalvanisiertes Stahlband (GI)

- Die Oberfläche ist mit einer Zinkschicht überzogen, die eine hervorragende Korrosionsbeständigkeit bietet.

- Geeignet für allgemeine Bau- und Haushaltsanwendungen.

Aluzink-Stahlband (GL)

Aluzink-Stahlband (GL)

- Die Aluzink-Beschichtung ist korrosionsbeständiger als Wärmegalvanisierung und besonders für strengere Umgebungen geeignet.

- Häufig in Außenbauten und Industrieanlagen eingesetzt.

Kaltgewalztes Stahlband (CR)

Kaltgewalztes Stahlband (CR)

- Die Oberfläche ist glatt und eben, aber die Korrosionsbeständigkeit ist schwach.

- Muss mit hochleistenden Beschichtungen verwendet werden.

Aluminiumspule

Aluminiumspule

- Leichtgewichtig, hohe Korrosionsbeständigkeit, geeignet für gewichtsensitive oder feuchte Umgebungen.

Beschichtungssystem:

Die Beschichtung ist der Schlüssel zur Funktion von farbigen Beschichtungsfolien, sie werden normalerweise in Grundierung, Oberlack und Rückseitenbeschichtung unterteilt:

Grundierung: Gewährleistet die Haftung der Beschichtung und verbessert die Korrosionsbeständigkeit des Trägers.

Grundierung: Gewährleistet die Haftung der Beschichtung und verbessert die Korrosionsbeständigkeit des Trägers.

Oberlack: Gewährt Farbe, Schönheit und Schutzfunktionen und bestimmt das endgültige Erscheinungsbild und die Leistung der farbigen Beschichtungsfolie.

Oberlack: Gewährt Farbe, Schönheit und Schutzfunktionen und bestimmt das endgültige Erscheinungsbild und die Leistung der farbigen Beschichtungsfolie.

Rückseitenfarbe: Verhindert Rückkorrosion, einige Produkte werden für eine beidseitige Dekoration verwendet.

Rückseitenfarbe: Verhindert Rückkorrosion, einige Produkte werden für eine beidseitige Dekoration verwendet.

Fertigungsprozess von farbigen Beschichtungsfolien:

Vorbehandlung:

Vorbehandlung:

Bevor farbige beschichtete Bänder hergestellt werden, muss das Substrat oberflächenbearbeitet werden, um die Haftung und den Beschichtungseffekt sicherzustellen. Die Oberflächenbehandlung umfasst die folgenden drei Schritte:

- Entfetten und Reinigen: Fett und Verunreinigungen entfernen.

- Säubern: Oxide entfernen und die Metalloberfläche freilegen.

- Chemische Behandlung: Durch Phosphatisierungs- oder Passivierungsprozess die Beschichtungshaftung verbessern.

Beschichtungsprozess:

Beschichtungsprozess:

Der Beschichtungsprozess von farbigen beschichteten Bändern umfasst die folgenden Schritte:

- Grundierung: - Das Grundierungslack wird durch präzise Rollbeschichtungsanlagen gleichmäßig auf die Oberfläche des Substrats aufgetragen.

- Decklackbeschichtung: - Der Decklack bestimmt Farbe und Schutzeffekt, und fortschrittliche Anlagen werden verwendet, um eine gleichmäßige Beschichtung zu gewährleisten.

- Rückseitenbeschichtung: - Eine dünne Schicht Lack auftragen, um Rückseitenkorrosion zu verhindern.

Gärung und Formgebung:

Gärung und Formgebung:

- Das beschichtete Substrat muss bei hoher Temperatur, normalerweise um die 200°C, gärt werden, damit die Beschichtung und das Substrat fest verklebt sind.

- Das gegärtete Material kann direkt durch Schneiden, Biegen usw. weiterverarbeitet werden.

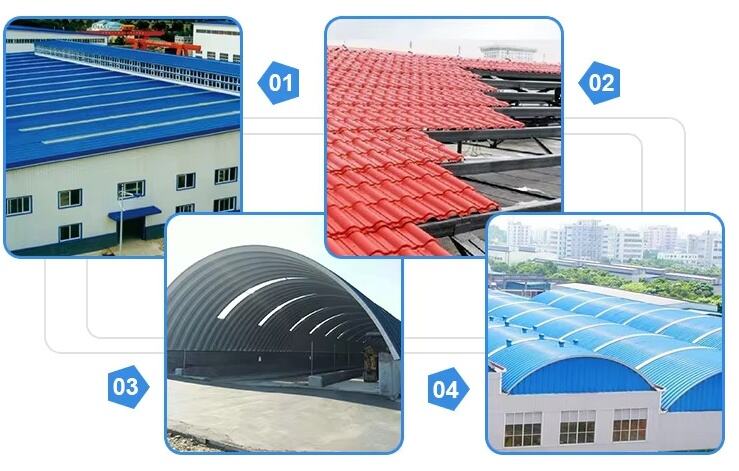

Anwendungsbereiche von farbigen Beschichtungsrollen:

Bauindustrie: Dachpaneelen, Wandpaneelen, Decken

Bauindustrie: Dachpaneelen, Wandpaneelen, Decken

Haushaltsgeräteindustrie: Kühlschrank-, Waschmaschinen- und Klimaanlagengehäuse

Haushaltsgeräteindustrie: Kühlschrank-, Waschmaschinen- und Klimaanlagengehäuse

Verkehr: Autofahrzeuggehäuse, Schiffdecks und Eisenbahnfahrzeuge usw.

Verkehr: Autofahrzeuggehäuse, Schiffdecks und Eisenbahnfahrzeuge usw.

Verpackung und andere Bereiche: Bunte metallene Verpackungskisten, Pinnwände, Möbeloberflächen usw.

Verpackung und andere Bereiche: Bunte metallene Verpackungskisten, Pinnwände, Möbeloberflächen usw.

Durch das Verständnis der Grundlagen von farbigen Beschichtungsrollen , können wir die richtigen Produkte besser auswählen, um ideale Leistung und Kosteneffizienz zu erreichen.

Wir sind ein professioneller Stahlhersteller. Wenn Sie Fragen haben, können Sie uns jederzeit kontaktieren!

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )  info@steelgroups.com

info@steelgroups.com