- Overview

- Related Products

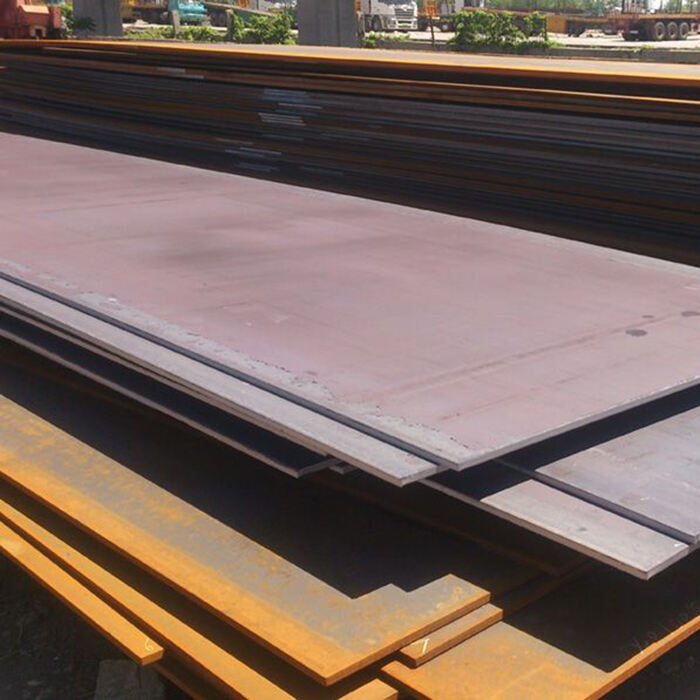

Description:

Description:

Q235D carbon steel is a high-quality ordinary carbon structural steel, and is the steel with the best low-temperature performance in the Q235 series. Compared with Q235A, B, and C grades, its core characteristics are excellent low-temperature impact toughness and stricter impurity control. The "Q" in the grade represents yield strength, "235" means that the lower limit of yield strength is 235MPa, and "D" indicates that its quality grade is D, which must meet the impact toughness requirements at -20℃, significantly improving the material's ability to resist brittle fracture in extreme low-temperature environments.

Features:

Q235D exhibits excellent adaptability to low-temperature environments. Its welding performance is better than other grades in the same series. Low-hydrogen electrodes can be used for welding. The preheating temperature before welding is required to be low (usually 50-100℃), and the toughness of the heat-affected zone after welding decreases slightly. It is particularly suitable for key welding parts such as liquefied natural gas storage tanks and polar research station steel structures. In terms of cold processing, the material can successfully complete cold bending, stamping and other processes. The 180° cold bending test with the bending core diameter equal to the thickness of the test piece is qualified, but it should be noted that the tendency of work hardening is more obvious. It is recommended to add annealing process for complex forming. According to the standard, the lower limit of the recommended operating temperature of Q235D can reach -40℃ (need to be verified in combination with specific design specifications), which is irreplaceable in scenes such as transmission towers and high-altitude bridges in the severe cold areas of Northeast China.

According to national standards, Q235D needs to be supplied in a fine-grained state, usually produced by hot rolling process, oxide scale is allowed on the surface, and shot peening or shot blasting can also be performed according to demand. In addition to conventional mechanical property tests, quality inspection must be carried out at -20℃ impact test, and ultrasonic flaw detection must be used to ensure that there are no defects such as stratification and slag inclusions inside the material. Compared with Q235C, its production cost increases by about 10%-15%, but it still has economic advantages compared with Q235E steel that needs to meet -40℃ impact performance. In terms of anti-corrosion treatment, Q235D needs to be hot-dip galvanized, epoxy zinc-rich primer and other enhanced protection, especially in marine climate or chemical corrosion environment, a composite anti-corrosion system needs to be used.

Specifications:

Specifications:

|

Product Name |

Q235 Carbon Steel Pipe |

|

Standard |

AISI ASTM JIS BS DIN GB |

|

Technique |

Hot Rolled |

|

Type |

Steel Pipe |

|

Thickness |

0.5-40 mm |

|

OD |

15-300mm |

|

Length |

5.8-12M |

|

Sample |

Sample Freely |

|

Packaging |

Standard seaworthy packaging or as required |

|

Payment |

T/T ; L/C ; |

Q235D Carbon Steel Tube Chemical Composition:

|

Grade |

C % |

Si % |

Mn % |

P % |

S % |

|

Q235D |

≤0.17 |

≤0.35 |

≤1.4 |

≤0.035 |

≤0.035 |

Q235D Carbon Steel Mechanical Property:

|

Thickness |

Yield Strength (Mpa) |

Tensile Strength |

Elongation |

Impact Energy |

|

|

(mm) |

(MPa) |

(%) |

Min |

||

|

≤ 16 |

235 |

370-500 |

26 |

0 |

27J |

|

> 16-40 |

225 |

370-500 |

25 |

0 |

27J |

|

>40 |

215 |

370-500 |

24 |

0 |

27J |

|

The min impact energy is longitudinal energy |

|||||

Applications:

Applications:

Q235D is prominently used in new energy equipment, special vehicle manufacturing and other fields, such as wind turbine tower, low-temperature LNG tanker chassis, polar engineering machinery skeleton and other scenes.

Tag:

Q235D Carbon Steel Pipe, China Carbon Steel PipeManufacturers, Suppliers, Factory, Carbon Steel, Carbon steel Tube,Carbon Steel Pipe,Q235 Carbon Steel Pipe,Q235A Carbon Steel Pipe,Q235B Carbon Steel Pipe,Q235C Carbon Steel Pipe