- Overview

- Related Products

Description:

Description:

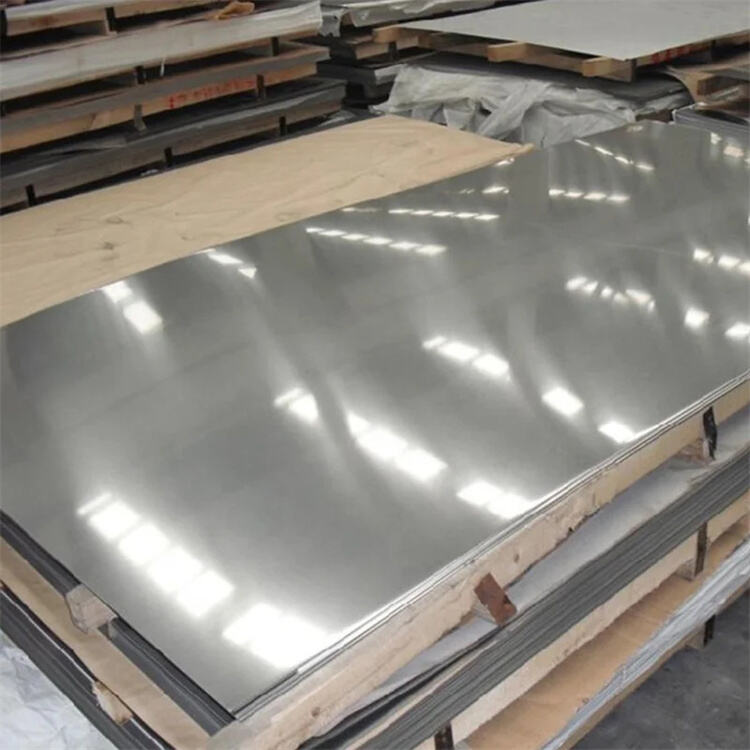

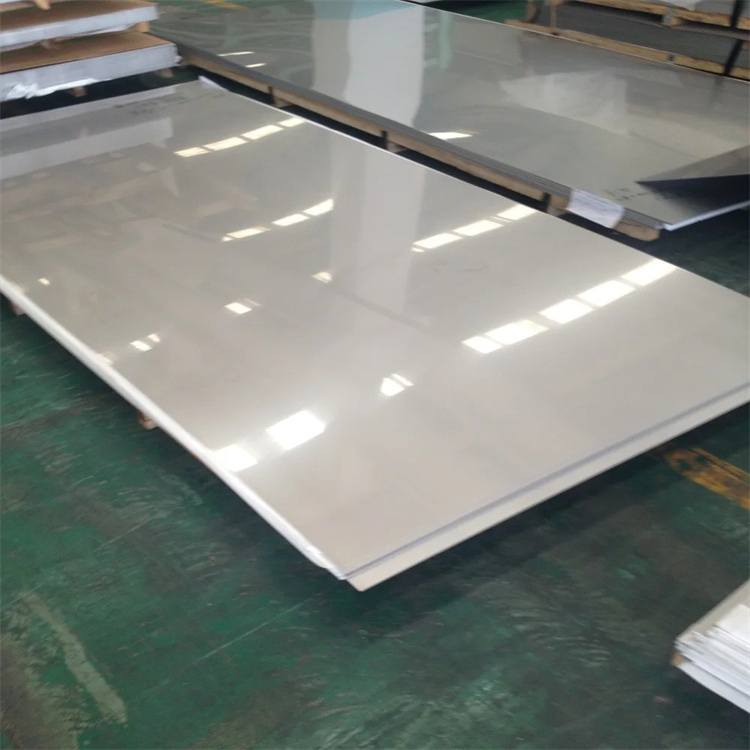

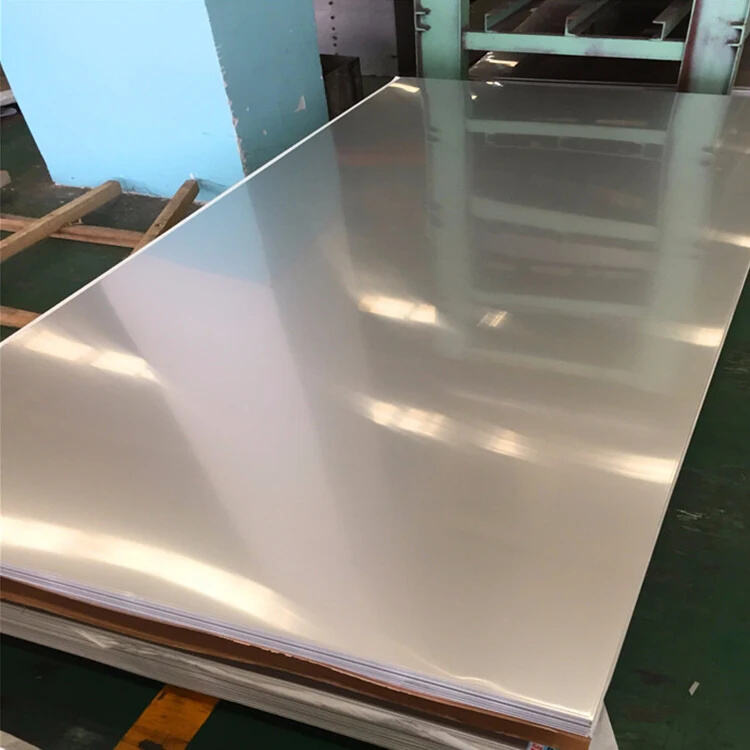

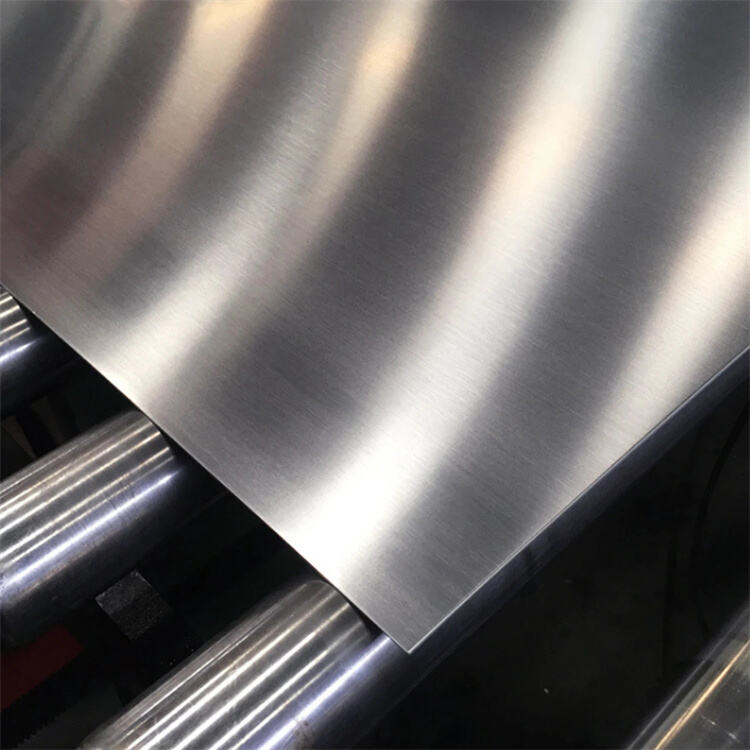

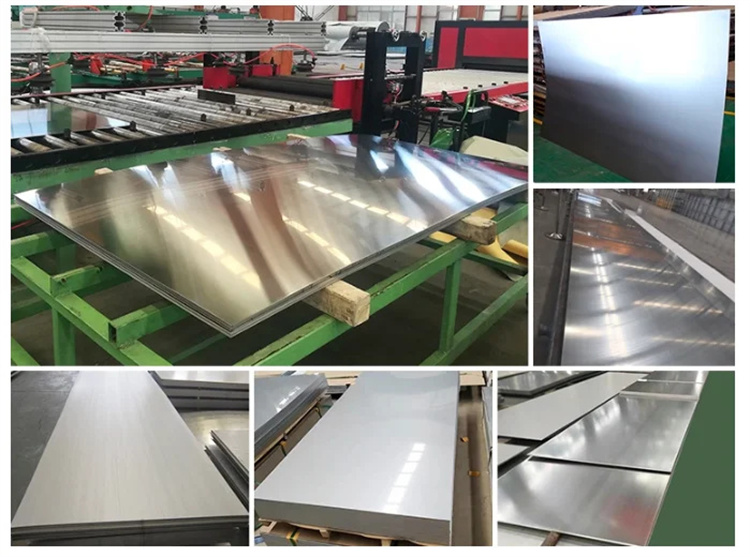

Polished stainless steel plate refers to a stainless steel plate obtained after polishing the stainless steel surface. Polishing is a process of removing surface defects and oxide films by stretching and cutting on the stainless steel surface with abrasives and abrasives to make the stainless steel surface smoother, flatter and more shiny.

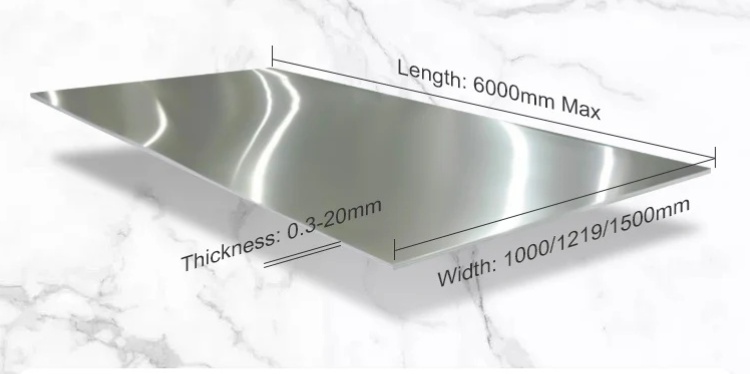

Specifications:

Specifications:

|

Product Name |

Stainless Steel Sheet/Plate |

|

Commodity |

Austenitic, Ferritic, Martensitic, Duplex, Cold rolled, Hot rolled |

|

Grade |

201、304、304L、321、316L、316Ti、317L、309S、310S、2205、2507、904L、253MA、254SMO、409、410、420、430, etc. |

|

Type |

Cold Rolled / Hot Rolled |

|

Thickness range |

Cold rolled:0.3~6mm, Hot rolled: 3mm~100mm |

|

Width range |

1000mm/1219mm/1250mm/ 1500mm/1800mm/2000mm or as customer's requirements |

|

Length |

100~12000mm or as customer's request |

|

Standards |

AISI ,ASTM, JIS, SUS, DIN, GB |

|

Surface |

N0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etc |

|

Certification |

BV, SGS, CE, TUV |

|

Delivery |

7-20 Days |

Chemical Composition of Polished SS Plate:

|

UNS |

ASTM |

EN |

JIS |

C% |

Mn% |

P% |

S% |

Si% |

Cr% |

Ni% |

Mo% |

|

S20100 |

201 |

1.4372 |

SUS201 |

≤0.15 |

5.5-7.5 |

≤0.06 |

≤0.03 |

≤1.00 |

16.0-18.0 |

3.5-5.5 |

- |

|

S20200 |

202 |

1.4373 |

SUS202 |

≤0.15 |

7.5-10.0 |

≤0.06 |

≤0.03 |

≤1.00 |

17.0-19.0 |

4.0-6.0 |

- |

|

S30100 |

301 |

1.4319 |

SUS301 |

≤0.15 |

≤2.00 |

≤0.045 |

≤0.03 |

≤1.00 |

16.0-18.0 |

6.0-8.0 |

- |

|

S30400 |

304 |

1.4301 |

SUS304 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

8.0-10.5 |

- |

|

S30403 |

304L |

1.4306 |

SUS304L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

8.0-12.0 |

- |

|

S30908 |

309S |

1.4833 |

SUS309S |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

22.0-24.0 |

12.0-15.0 |

- |

|

S31008 |

310S |

1.4845 |

SUS310S |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤1.50 |

24.0-26.0 |

19.0-22.0 |

- |

|

S31600 |

316 |

1.4401 |

SUS316 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

S31603 |

316L |

1.4404 |

SUS316L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

S31703 |

317L |

1.4438 |

SUS317L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

11.0-15.0 |

3.0-4.0 |

|

S32100 |

321 |

1.4541 |

SUS321 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

17.0-19.0 |

9.0-12.0 |

- |

|

S34700 |

347 |

1.455 |

SUS347 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

17.0-19.0 |

9.0-13.0 |

- |

|

S40500 |

405 |

1.4002 |

SUS405 |

≤0.08 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

11.5-14.5 |

≤0.60 |

- |

|

S40900 |

409 |

1.4512 |

SUS409 |

≤0.08 |

≤1.00 |

≤0.045 |

≤0.03 |

≤1.00 |

10.5-11.75 |

≤0.50 |

- |

|

S43000 |

430 |

1.4016 |

SUS430 |

≤0.12 |

≤1.00 |

≤0.040 |

≤0.03 |

≤0.75 |

16.0-18.0 |

≤0.60 |

- |

|

S43400 |

434 |

1.4113 |

SUS434 |

≤0.12 |

≤1.00 |

≤0.040 |

≤0.03 |

≤1.00 |

16.0-18.0 |

- |

- |

|

S44400 |

444 |

1.4521 |

SUS444L |

≤0.025 |

≤1.00 |

≤0.045 |

≤0.03 |

≤1.00 |

17.5-19.5 |

≤1.00 |

- |

|

S40300 |

403 |

- |

SUS403 |

≤0.15 |

5.5-7.5 |

≤0.04 |

≤0.03 |

≤0.50 |

11.5-13.0 |

≤0.60 |

- |

|

S410000 |

410 |

1.40006 |

SUS410 |

≤0.15 |

≤1.00 |

≤0.035 |

≤0.03 |

≤1.00 |

11.5-13.5 |

≤0.60 |

≤1.00 |

|

S42000 |

420 |

1.4021 |

SUS420J1 |

0.16~0.25 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

12.0-14.0 |

≤0.75 |

≤1.00 |

|

S440A |

440A |

1.4028 |

SUS440A |

0.60~0.75 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

16.0-18.0 |

- |

≤0.75 |

|

S32750 |

SAD2507 |

1.441 |

|

≤0.03 |

≤1.2 |

≤0.035 |

≤0.02 |

≤0.80 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

|

S31803 |

SAF2205 |

1.4462 |

|

≤0.03 |

≤2.0 |

≤0.03 |

≤0.02 |

≤1.00 |

21.0-23.0 |

4.0-6.5 |

2.5-3.5 |

|

N08904 |

904L |

1.4539 |

|

≤0.0.3 |

≤2.0 |

≤0.035 |

≤0.03 |

≤1.00 |

18.0-20.0 |

23.0-25.0 |

3.0-4.0 |

What Are the Features of Polished Stainless Steel Sheet?

What Are the Features of Polished Stainless Steel Sheet?

High hardness: Polished stainless steel plate has excellent mechanical properties and strength, high hardness and wear resistance.

High hardness: Polished stainless steel plate has excellent mechanical properties and strength, high hardness and wear resistance.

Strong corrosion resistance: Polished stainless steel plate has good corrosion resistance and can resist oxidation, acid, alkali and other chemical components.

Strong corrosion resistance: Polished stainless steel plate has good corrosion resistance and can resist oxidation, acid, alkali and other chemical components.

Good heat resistance: Polished stainless steel plate can also maintain good mechanical properties and chemical stability under high temperature environment.

Good heat resistance: Polished stainless steel plate can also maintain good mechanical properties and chemical stability under high temperature environment.

Good aesthetics: The surface of the polished stainless steel plate is very smooth and mirror-like, which looks very delicate, can improve the decorativeness of the product and enhance the aesthetics of the product.

Good aesthetics: The surface of the polished stainless steel plate is very smooth and mirror-like, which looks very delicate, can improve the decorativeness of the product and enhance the aesthetics of the product.

Applications:

Applications:

Food processing equipment: food processing machines, tableware, stoves, etc.

Food processing equipment: food processing machines, tableware, stoves, etc.

Medical equipment and equipment: surgical instruments, operating tables, etc.

Medical equipment and equipment: surgical instruments, operating tables, etc.

Petroleum, chemical and pharmaceutical equipment: reactors and storage tanks, etc.

Petroleum, chemical and pharmaceutical equipment: reactors and storage tanks, etc.

Building decoration: indoor and outdoor building materials.

Building decoration: indoor and outdoor building materials.

FAQ:

FAQ:

1.Q: How long can make delivery?

A: For stock products, will make shipments in 5- 7 days after receiving deposit; for products need new production for common materials, usually make shipments in 10-15 days; for products need new production for special and rare materials, usually need 20-30 days to make shipment.

2.Q:Can I visit your factory?

A: Sure,welcome to you visit our factory at any time.

3.Q:Where are you?

A: Anyang in Henan Province.

4.Q: What certifications do your products have?

A: We have ISO 9001,BV, SGS, CE, TUV and other certifications.

5.Q:What are your terms of payment?

A:30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100%.Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A.

Tag:

Polished Stainless Steel Plate, China Stainless Steel Plate manufacturers, suppliers, factory, Stainless Steel Tube,201 stainless steel sheet, 316 stainless steel sheet, 316L Stainless Steel Plate ,wear resistant steel plate, 304 Stainless Steel Plate ,430 Stainless Steel Plate,202 Stainless Steel Plate ,310S Stainless Steel Plate,410 Stainless Steel Plate