- Overview

- Related Products

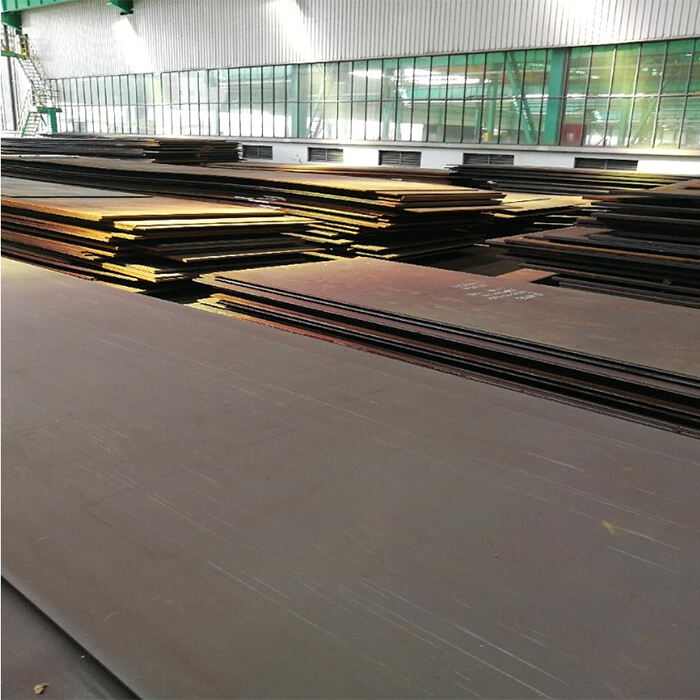

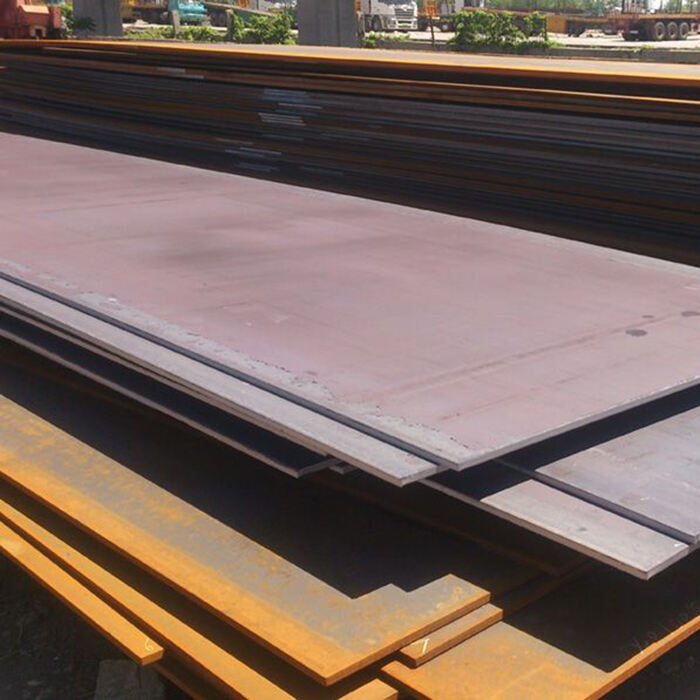

Description:

Description:

The "NM" in NM600 refers to the wear-resistant plate, the first letters of "Nai" and "Mo", and 600 is the Brinell hardness value HB value. The grade is higher than NM500, NM450, NM400, and NM360.

NM600 implementation standard: implement enterprise standard Q/XGJ166-2009

Delivery status: quenching and tempering (quenching + tempering)

Specifications:

Specifications:

|

Product Name |

Wear-Resistant Steel Sheet Plate |

|

Steel Grade |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Thickness |

2mm-300mm |

|

Width |

500-2500mm |

|

Length |

1000mm-12000mm or according to customer's special request |

|

Tolerance |

Thickness: +/-0.02mm, Width:+/-2mm |

|

Delivery Time |

7-15 working days after the receipt of 30% deposit |

|

Certification |

BV SGS CE TUV |

|

Package |

Bundle with steel strip,Container shipping |

NM600 Steel Standard Comparison:

|

Steel Grade |

SSAB |

Thyssenkrupp |

JFE |

DILLIDUR |

Ruukki |

|

NM600 |

HARDOX600 |

XAR600 |

- |

600V |

Raex600 |

NM600 Abrasion Resistance Steel Plate Chemical Element Composition Content (%)

|

Component |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

B |

Al |

|

Minimum Value |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Maximum Value |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

NM600 Wear Resistant Steel Plate Mechanical Properties:

|

Thickness |

Tensile Strength |

Elongation or Extension Rate |

Hardness |

|

t≤60 |

- |

- |

Surface Hardness: 570~640HBW |

Advantages of NM600:

High wear resistance: The carbon content in the chemical composition of the alloy wear-resistant layer is 4-5%, and the chromium content is as high as 25-30%. The volume fraction of Cr7C3 carbide in its metallographic structure reaches more than 50%, the macro hardness is HRC56-62, and the hardness of chromium carbide is HV1400-1800. Because the carbides are distributed perpendicular to the wear direction, even compared with the casting alloys with the same composition and hardness, the wear resistance is more than doubled.

High wear resistance: The carbon content in the chemical composition of the alloy wear-resistant layer is 4-5%, and the chromium content is as high as 25-30%. The volume fraction of Cr7C3 carbide in its metallographic structure reaches more than 50%, the macro hardness is HRC56-62, and the hardness of chromium carbide is HV1400-1800. Because the carbides are distributed perpendicular to the wear direction, even compared with the casting alloys with the same composition and hardness, the wear resistance is more than doubled.

Good impact resistance: The substrate of the wear-resistant composite steel plate is a tough material such as low-carbon steel or low-alloy, which reflects the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the substrate bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of high-drop hoppers in material conveying systems.

Good impact resistance: The substrate of the wear-resistant composite steel plate is a tough material such as low-carbon steel or low-alloy, which reflects the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the substrate bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of high-drop hoppers in material conveying systems.

Good heat resistance: The alloy wear-resistant layer is recommended to be used under ≤600 working conditions. If vanadium, molybdenum and other alloys are added to the alloy wear-resistant layer, it can withstand high-temperature wear of ≤800. The recommended operating temperature is as follows: Ordinary carbon steel substrates are recommended to be used under working conditions not higher than 380; Low alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, etc.) substrates are recommended to be used under working conditions not higher than 540; Heat-resistant stainless steel substrates are recommended to be used under working conditions not higher than 800.

Good heat resistance: The alloy wear-resistant layer is recommended to be used under ≤600 working conditions. If vanadium, molybdenum and other alloys are added to the alloy wear-resistant layer, it can withstand high-temperature wear of ≤800. The recommended operating temperature is as follows: Ordinary carbon steel substrates are recommended to be used under working conditions not higher than 380; Low alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, etc.) substrates are recommended to be used under working conditions not higher than 540; Heat-resistant stainless steel substrates are recommended to be used under working conditions not higher than 800.

Applications:

Applications:

NM600 is widely used in metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and tiles and other industries.

Product Packing:

Product Packing:

We uses the most safest and the most effective ways of packaging for all types of deliveries.

FAQ:

FAQ:

1.Q: How long can make delivery?

A: For stock products, will make shipments in 5- 7 days after receiving deposit; for products need new production for common materials, usually make shipments in 10-15 days; for products need new production for special and rare materials, usually need 20-30 days to make shipment.

2.Q:Can I visit your factory?

A: Sure,welcome to you visit our factory at any time.

3.Q:Where are you?

A: Anyang in Henan Province.

4.Q: What certifications do your products have?

A: We have ISO 9001,BV, SGS, CE, TUV and other certifications.

5.Q:What are your terms of payment?

A:30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100%.Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A.

Tag:

NM600, China Abrasion Resistant Steel Sheet Manufacturers, Suppliers, Factory, NM300Wear Resistant SteelSheet, NM360Wear Resistant SteelSheet, NM500Wear Resistant SteelSheet,High Wear Resistance And High Toughness,High Quality,NM600 Wear Resistant Steel Plate,NM300TP,NM400,NM400E,NM450,NM450E,NM500,NM500E