- Overview

- Related Products

Description:

Description:

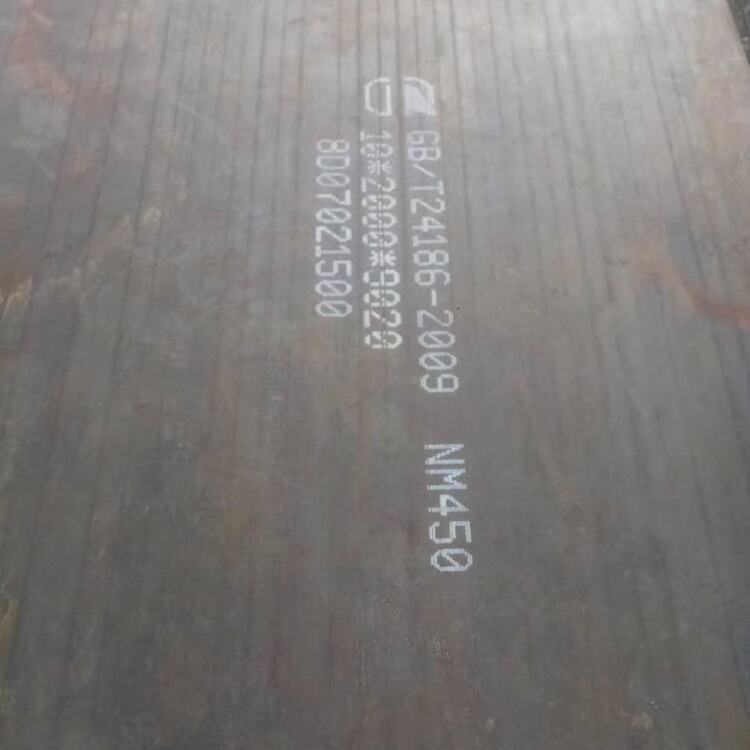

NM450 is a highly wear-resistant steel, belonging to the wear-resistant plate series. The "450" in NM450 represents its hardness (usually expressed in Brinell hardness HB), that is, the hardness of the steel plate is about 450HB. "NM" is the first letter of the Chinese word for "NaiMo".

NM450 steel plates are usually made of low-alloy steel and high-carbon steel materials, and undergo special treatment of the wear-resistant layer, such as quenching, tempering and other heat treatment processes, to achieve the purpose of improving its hardness and strength. There are usually certain alloy elements on the surface of the steel plate, such as molybdenum, chromium, manganese, etc., which help to improve wear resistance.

Heat treatment process of NM450 steel plate:

Quenching: After the steel plate is heated to a certain temperature, it is quickly cooled to increase its hardness. The quenching process is a key step to improve the hardness and wear resistance of NM450 steel plate.

Quenching: After the steel plate is heated to a certain temperature, it is quickly cooled to increase its hardness. The quenching process is a key step to improve the hardness and wear resistance of NM450 steel plate.

Tempering: In order to avoid excessive brittleness of the steel plate, the quenched steel plate is usually tempered. The tempering process controls the structure of the steel plate through heating and cooling, improves its toughness and stability, and prevents cracks or brittle fractures during use.

Tempering: In order to avoid excessive brittleness of the steel plate, the quenched steel plate is usually tempered. The tempering process controls the structure of the steel plate through heating and cooling, improves its toughness and stability, and prevents cracks or brittle fractures during use.

These heat treatment processes can not only enhance the surface hardness of the NM450 steel plate, but also improve its wear resistance and extend its service life while ensuring the toughness of the steel plate.

Specifications:

Specifications:

|

Product Name |

Wear-Resistant Steel Sheet Plate |

|

Steel Grade |

NM300,NM300TP,NM360, NM400, NM450, NM500, NM550, NM600, |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Thickness |

2mm-300mm |

|

Width |

500-2500mm |

|

Length |

1000mm-12000mm or according to customer's special request |

|

Tolerance |

Thickness: +/-0.02mm, Width:+/-2mm |

|

Delivery Time |

7-15 working days after the receipt of 30% deposit |

|

Certification |

BV SGS CE TUV |

|

Package |

Bundle with steel strip,Container shipping |

Abrasion Resistant Steel Plate Chemical Composition(%):

|

Steel Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

B |

|

NM360 |

0.17 max |

0.50 max |

1.50 max |

0.025 max |

0.015 max |

0.70 max |

0.50 max |

0.40 max |

0.005 max |

|

NM400 |

0.24 max |

0.50 max |

1.60 max |

0.025 max |

0.015 max |

0.40-0.80 |

0.20-0.50 |

0.20-0.50 |

0.005 max |

|

NM450 |

0.26 max |

0.70 max |

1.60 max |

0.025 max |

0.015 max |

1.50 max |

1.00 max |

0.50 max |

0.004 max |

|

NM500 |

0.38 max |

0.70 max |

1.70 max |

0.020 max |

0.010 max |

1.20 max |

1.00 max |

0.65 max |

0.005-0.006 |

Abrasion Resistant Steel Sheet Mechanical Properties:

|

Steel Grade |

Y.S (MPa) |

T.S (MPa) |

Elongation A5(%) |

Impact Test |

Hardness |

|

|

min |

min |

min |

(°C) |

AKV J(min) |

HBW |

|

|

NM360 |

800 |

1000 |

10 |

-20 |

30 |

320-400 |

|

NM400 |

1000 |

1250 |

10 |

-20 |

30 |

360-440 |

|

NM450 |

1250 |

1500 |

10 |

-20 |

30 |

410-490 |

|

NM500 |

1300 |

1700 |

10 |

-20 |

30 |

450-540 |

Applications:

Applications:

(1) Engineering machinery and equipment: bucket plates, side blade plates, bucket bottom plates, blades, and blades of loaders, bulldozers, and excavators.

(2) Loading and unloading machinery and equipment: unloading mill chain plates, hopper liners, grab blade plates, and medium-sized automatic dump truck dump plates

(3) Construction machinery and equipment: cement pusher tooth plates, concrete mixer liners, mixing floor liners, and dust collector liners

(4) Metallurgical machinery and equipment: iron ore sintering conveying elbows, iron ore sintering machine liners, and scraper liners

(5) Mining machinery and equipment: ore and stone crusher liners and blades.

(6) Thermal power equipment: coal mill liners, coal hoppers, coal distribution pipes, coal distribution grids, and coal unloading equipment liners

Product Packing:

Product Packing:

We uses the most safest and the most effective ways of packaging for all types of deliveries.

FAQ:

FAQ:

1.Q: How long can make delivery?

A: For stock products, will make shipments in 5- 7 days after receiving deposit; for products need new production for common materials, usually make shipments in 10-15 days; for products need new production for special and rare materials, usually need 20-30 days to make shipment.

2.Q:Can I visit your factory?

A: Sure,welcome to you visit our factory at any time.

3.Q:Where are you?

A: Anyang in Henan Province.

4.Q: What certifications do your products have?

A: We have ISO 9001,BV, SGS, CE, TUV and other certifications.

5.Q:What are your terms of payment?

A:30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100%.Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A.

Tag:

NM450, China Abrasion Resistant Steel Sheet Manufacturers, Suppliers, Factory, NM300Wear Resistant SteelSheet, NM360Wear Resistant SteelSheet, NM500Wear Resistant SteelSheet,High Wear Resistance And High Toughness,High Quality,NM600 Wear Resistant Steel Plate,NM300TP,NM400,NM400E