- Pregled

- Srodni proizvodi

Opis:

Opis:

Oznaka "NM" u NM600 se odnosi na otopinu otpornu na iznosenje, prve slova riječi "Nai" i "Mo", a 600 je vrijednost tvrdoće po Brinellu (HB). Obrt je viši od NM500, NM450, NM400 i NM360.

Standard za NM600: primjenjuje se poduzećanski standard Q/XGJ166-2009

Status isporuke: utvrdjivanje i otpaljivanje (utvrdjivanje + otpaljivanje)

Sljedeći članak:

Sljedeći članak:

|

Naziv proizvoda |

Čelikasta ploča otporna na nošenje |

|

Odlomak čelika |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

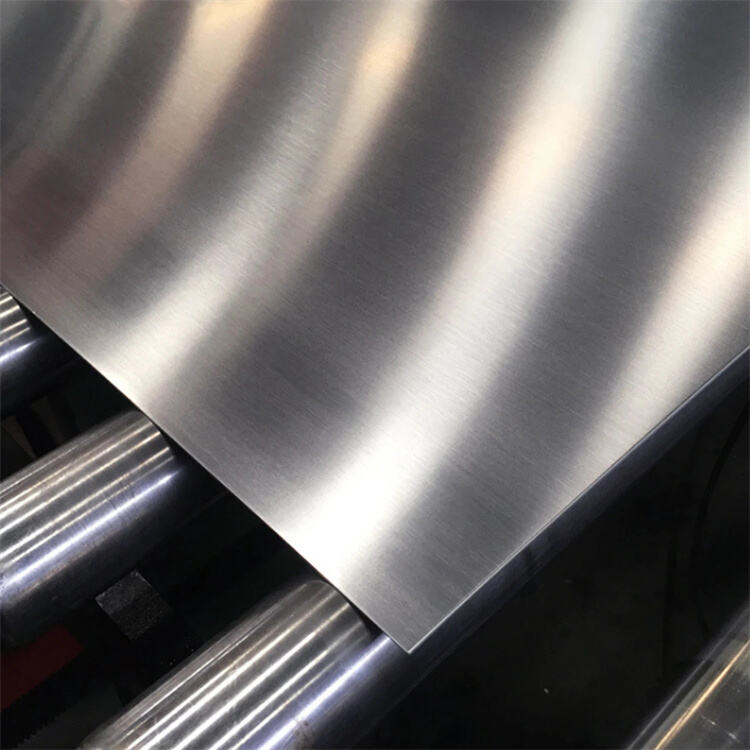

Debljina |

2mm-300mm |

|

Širina |

500-2500mm |

|

Duljina |

1000mm-12000mm ili prema posebnom zahtjevu kupca |

|

S obzirom na to |

Debljina: +\/-0,02mm, Širina: +\/-2mm |

|

Vrijeme isporuke |

7-15 radnih dana nakon primanja 30% prijedloga |

|

Certifikacija |

BV SGS CE TUV |

|

Pakiranje |

Bundling s očinkom, Kontejnerska dostava |

Usporedba standarda otopine NM600:

|

Odlomak čelika |

SSAB |

ThyssenKrupp |

JFE |

DILLIDUR |

Ruukki |

|

Nm600 |

HARDOX600 |

XAR600 |

- |

600V |

Raex600 |

Ploča otopine otporne na iznosenje NM600 Sastav kemijskih elemenata (%)

|

Komponenta |

C |

Si |

Mn |

P |

S |

CR |

Ni |

Mo |

Ti |

B |

AL |

|

Minimalna vrijednost |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Maksimalna vrijednost |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

NM600 Iznos Mehanički svojstvi otporne otopine od čelika:

|

Debljina |

Soprtnost na povlačenje |

Procenat dugačanja ili brzina produženja |

Tvrdoća |

|

t≤60 |

- |

- |

Tvrdost površine: 570~640HBW |

Prednosti NM600:

Visoka otpornost na otrisivanje: Sadržaj ugljika u kemikalnoj sastavi sloja odoljnog protiv otrisivanja je 4-5%, a sadržaj hromija iznosi čak 25-30%. U njegovoj metalografskoj strukturi, volumenski udio karbida Cr7C3 dostiže više od 50%, makroskopska tvrdost je HRC56-62, a tvrdost hromovih karbida je HV1400-1800. Budući da su karbidi raspoređeni okomito na smjer otrisivanja, čak i usporedbom s lisanim alijansama iste sastave i tvrdosti, otpornost na otrisivanje je više od dvostruko veća.

Visoka otpornost na otrisivanje: Sadržaj ugljika u kemikalnoj sastavi sloja odoljnog protiv otrisivanja je 4-5%, a sadržaj hromija iznosi čak 25-30%. U njegovoj metalografskoj strukturi, volumenski udio karbida Cr7C3 dostiže više od 50%, makroskopska tvrdost je HRC56-62, a tvrdost hromovih karbida je HV1400-1800. Budući da su karbidi raspoređeni okomito na smjer otrisivanja, čak i usporedbom s lisanim alijansama iste sastave i tvrdosti, otpornost na otrisivanje je više od dvostruko veća.

Dobra otpornost na udar: Podloga nošive slojeve kompozitne otopine je tvrd materijal poput niskougljičaste ocele ili s manjom lomovinom, što odražava prednosti bimetalne strukture. Nošivi sloj se suočava s nošivim sredstvima, dok podloga nose težinu sredstva, stoga ima izuzetnu otpornost na udar. Može izdržati udar i nošenje visokih lupeta u sustavima za prijenos materijala.

Dobra otpornost na udar: Podloga nošive slojeve kompozitne otopine je tvrd materijal poput niskougljičaste ocele ili s manjom lomovinom, što odražava prednosti bimetalne strukture. Nošivi sloj se suočava s nošivim sredstvima, dok podloga nose težinu sredstva, stoga ima izuzetnu otpornost na udar. Može izdržati udar i nošenje visokih lupeta u sustavima za prijenos materijala.

Dobra otpornost na toplinu: Preporuča se da se sloj odnosnog spoja koristi u radnim uvjetima ≤600. Ako se u sloj odnosnog spoja dodaju vanadij, molibden i drugi spojevi, može izdržati visokotemperaturno odnosno ≤800. Preporučena radna temperatura je sljedeća: Obične ugljikovne ocele preporuča se koristiti u radnim uvjetima ne višim od 380; Podloge od niskospojnog toplinsko otpornog čelika (15CrMo, 12Cr1MOV itd.) preporuča se koristiti u radnim uvjetima ne višim od 540; Podloge od toplinsko otpornog nerđajućeg čelika preporuča se koristiti u radnim uvjetima ne višim od 800.

Dobra otpornost na toplinu: Preporuča se da se sloj odnosnog spoja koristi u radnim uvjetima ≤600. Ako se u sloj odnosnog spoja dodaju vanadij, molibden i drugi spojevi, može izdržati visokotemperaturno odnosno ≤800. Preporučena radna temperatura je sljedeća: Obične ugljikovne ocele preporuča se koristiti u radnim uvjetima ne višim od 380; Podloge od niskospojnog toplinsko otpornog čelika (15CrMo, 12Cr1MOV itd.) preporuča se koristiti u radnim uvjetima ne višim od 540; Podloge od toplinsko otpornog nerđajućeg čelika preporuča se koristiti u radnim uvjetima ne višim od 800.

Primjene:

Primjene:

NM600 široko se koristi u metalurgiji, uglju, cementu, elektroenergetici, staklu, rudarstvu, građevinama, cijevima i drugim industrijskim granama.

Upakovanje proizvoda:

Upakovanje proizvoda:

Mi koristimo najsigurnije i najučinkovitije načine pakiranja za sve vrste dostava.

Česta pitanja:

Česta pitanja:

1.Q: Koliko dugo traje dostava?

A: Za robe na zalihi, šalju se otpreme 5-7 dana nakon primanja depozita; za robe koje zahtijevaju novu proizvodnju za obične materijale, obično se otpreme šalju u roku od 10-15 dana; za robe koje zahtijevaju novu proizvodnju za posebne i rijetke materijale, obično je potreban rok od 20-30 dana za otpremu.

2.Q: Možem li posjetiti vaš zavod?

O: Naravno, dobrodošli da posjetite našu tvornicu u bilo koje vrijeme.

3.Q: Gdje ste?

A: U Anyangu, provincija Henan.

4.Q: Kojim certifikatima su opremljeni vaši proizvodi?

A: Imamo ISO 9001, BV, SGS, CE, TUV i druge certifikate.

5.Q: Koje su vaše uvjete plaćanja?

A: 30% T/T depozit unaprijed, 70% T/T iznosa unutar 5 dana nakon kopije B/L-a, 100%. Nepovratna L/C na pogled, 100% nepovratna L/C nakon primanja B/L-a 30-120 dana, O/A.

Oznaka:

NM600, Kineski proizvođači otopina protiv iznosenja NM300, NM360, NM500, listova od otopine za otpornost na iznosenje, Visoka otpornost na iznosenje i visoka tvrdoća, Visoka kvaliteta, Otpornina na nošenje čeljusti od ocele NM600 ,NM300TP ,NM400 ,NM400E ,Nm450 ,NM450E ,Nm500 ,NM500E