- Overview

- Related Products

Description:

Hot-dip galvanization (galvanization), also known as hot-dip galvanizing and hot-dip galvanizing, is an effective metal anti-corrosion method, which is mainly used in metal structure facilities in various industries. It is to immerse the derusted steel parts in molten zinc at about 500 ° C, so that a layer of zinc is attached to the surface of the steel parts, so as to achieve the purpose of anticorrosion.

Hot-dip galvanizing process: finished product pickling-washing-adding auxiliary plating solution-drying-rack plating-cooling-medicinal chemistry-cleaning-polishing-hot-dip galvanizing is completed.

Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel pipe substrate and the plating solution, forming a corrosion-resistant zinc-iron alloy layer with a tight structure. The alloy layer is combined with the pure zinc layer and steel pipe matrix. So its corrosion resistance is strong.

Specifications:

|

Product Name |

Galvanized Steel Tube |

|

Out Diameter |

Pre galvanized:1/2''-4''(21.3-114.3mm). Such as 38.1mm, 42.3mm, 48.3mm, 48.6mm or as customer request. |

|

Hot dipped galvanized:1/2''-24''(21.3mm-600mm). Such as 21.3mm, 33.4mm, 42.3mm, 48.3mm, 114.3mm or as customer request. |

|

|

Thickness |

Pre galvanized:0.6-2.5mm. |

|

Hot dipped galvanized: 0.8- 25mm. |

|

|

Zinc coating |

Pre galvanized:5μm-25μm |

|

Hot dipped galvanized:35μm-240μm |

|

|

Type |

Electronic Resistance Welded (ERW) |

|

Steel Grade |

Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D..... |

|

Standard |

BS1139-1775, EN1039, EN10219, JIS G3444:2004, GB/T3091-2001, BS1387-1985, DIN EN10025, ASTM A53 SCH40/80/STD, BS-EN10255-2004 |

|

Surface Finish |

Pre-galvanized, Hot dipped galvanized, Electro galvanized, Black, Painted, Threaded, Engraved, Socket. |

|

International Standard |

ISO 9000-2001, CE CERTIFICATE, BV CERTIFICATE |

Application:

1. Construction industry: Galvanized tube is often used in the structural skeleton of buildings, stairs and guardrails, etc., because it has the characteristics of strong and durable, anti-corrosion, and weather-resistant.

2. Air conditioning industry: Galvanized tubes are also widely used in air conditioning systems to connect condensers, evaporators, compressors and cooling towers and other equipment, as well as to make air conditioning pipes and fittings.

3. Water supply and drainage industry: Galvanized tubes are also often used in water supply and drainage pipeline systems, such as water supply pipelines, fire water pipes, sewage treatment pipelines, etc.

4. Oil and gas industry: Galvanized tubes are also widely used in the oil and gas industry, such as oil pipelines, natural gas pipelines, pipelines that transport oil and natural gas, etc.

5. Telecommunications industry:Galvanized tubes are an important part of cable routes, such as support frames or cable ducts used to form wires.

6. Industrial field:Galvanized tubes are usually used in pipelines that transport non-corrosive liquids such as water, gas, grease, etc., such as chemical plants, oil refineries, food processing plants, etc.

Manufacturing process of galvanized pipe:

The manufacturing of galvanized pipes mainly includes the following steps:

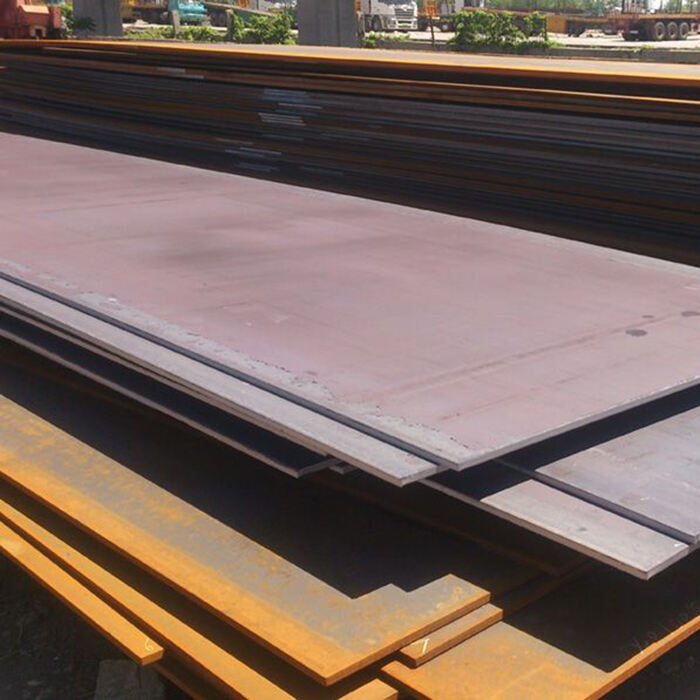

Steel pipe production: First, the hot rolling or cold rolling process is used to produce steel pipes of the required specifications. These steel pipes can be seamless or welded.

Steel pipe production: First, the hot rolling or cold rolling process is used to produce steel pipes of the required specifications. These steel pipes can be seamless or welded.

Cleaning treatment: Before galvanizing, the steel pipe must be thoroughly cleaned to remove oil, rust and other impurities on the surface to ensure the adhesion of the galvanized layer.

Cleaning treatment: Before galvanizing, the steel pipe must be thoroughly cleaned to remove oil, rust and other impurities on the surface to ensure the adhesion of the galvanized layer.

Pickling: Immerse the cleaned steel pipe in an acidic solution to remove oxides on the surface and improve the surface roughness, which is beneficial to the adhesion of the zinc layer.

Pickling: Immerse the cleaned steel pipe in an acidic solution to remove oxides on the surface and improve the surface roughness, which is beneficial to the adhesion of the zinc layer.

Hot-dip galvanizing: The pickled steel pipe is passed through the molten zinc liquid for hot-dip galvanizing. At high temperatures, zinc reacts chemically with the surface of the steel pipe to form a dense and uniform zinc layer.

Hot-dip galvanizing: The pickled steel pipe is passed through the molten zinc liquid for hot-dip galvanizing. At high temperatures, zinc reacts chemically with the surface of the steel pipe to form a dense and uniform zinc layer.

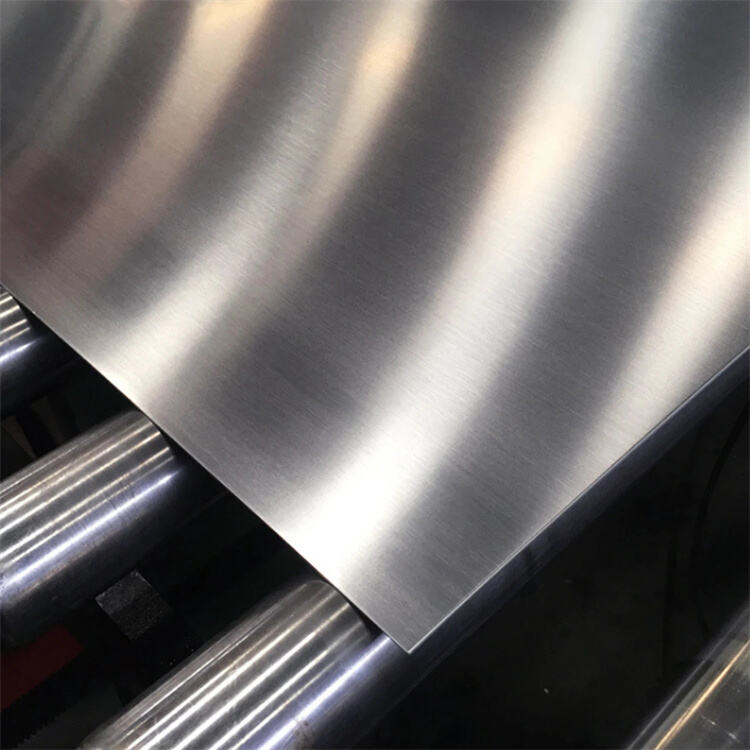

Cooling and finishing: After galvanizing is completed, the steel pipe is cooled and finished to ensure the smoothness and flatness of the surface.

Cooling and finishing: After galvanizing is completed, the steel pipe is cooled and finished to ensure the smoothness and flatness of the surface.

Inspection and packaging: Conduct quality inspection on galvanized pipes, including appearance inspection, thickness measurement, adhesion test, etc. After passing the test, they will be packaged and labeled for transportation and use.

Inspection and packaging: Conduct quality inspection on galvanized pipes, including appearance inspection, thickness measurement, adhesion test, etc. After passing the test, they will be packaged and labeled for transportation and use.

How does it work?

Galvanizing can protect metal is a number of ways. Firstly, it creates a protective coating that shields the metal from the surrounding environment. The layer of zinc prevents water and moisture and other elements in the air from corroding the steel underneath. Should the zinc coating be scratched deep enough, the metal would become exposed and susceptible to corrosion.

Galvanizing can protect metal is a number of ways. Firstly, it creates a protective coating that shields the metal from the surrounding environment. The layer of zinc prevents water and moisture and other elements in the air from corroding the steel underneath. Should the zinc coating be scratched deep enough, the metal would become exposed and susceptible to corrosion.

Galvanizing can also protect metal through a process called "galvanic corrosion". Galvanic corrosion occurs when two metals of a different electrochemical make up are placed into contact with one another with an electrolyte present, such as salty water. Depending on the atomic structure of the two metals, one metal is the anode and the other is the cathode. The anode corrodes more rapidly than it would by itself and the cathode corrodes at a slower pace than it would by itself. The reason zinc is used for galvanizing is because it has an affinity towards being the anode when in contact with many different types of metals. Since the zinc coating in contact with the base metal is usually the anode, it slows the corrosion of the base metal, or the cathode.

Galvanizing can also protect metal through a process called "galvanic corrosion". Galvanic corrosion occurs when two metals of a different electrochemical make up are placed into contact with one another with an electrolyte present, such as salty water. Depending on the atomic structure of the two metals, one metal is the anode and the other is the cathode. The anode corrodes more rapidly than it would by itself and the cathode corrodes at a slower pace than it would by itself. The reason zinc is used for galvanizing is because it has an affinity towards being the anode when in contact with many different types of metals. Since the zinc coating in contact with the base metal is usually the anode, it slows the corrosion of the base metal, or the cathode.

FAQ:

Q1: What is your terms of payment?

A: Normally 30% T/T as the upfront deposit, 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: What is the terms of delivery?

A: EXW, FOB, CIF, CFR, DDU

Q3: What is the terms of packing?

A: Generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days - 30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the compliment samples?

A: Yes, we provide the free samples if available in stocks, the transportation fee is borne by buyer.

Tag:

Galvanized Steel Pipe, China Galvanized Steel Tube Manufacturers, Suppliers, Factory,Coated steel, Galvanized Steel Coil, Galvanized Steel Plate