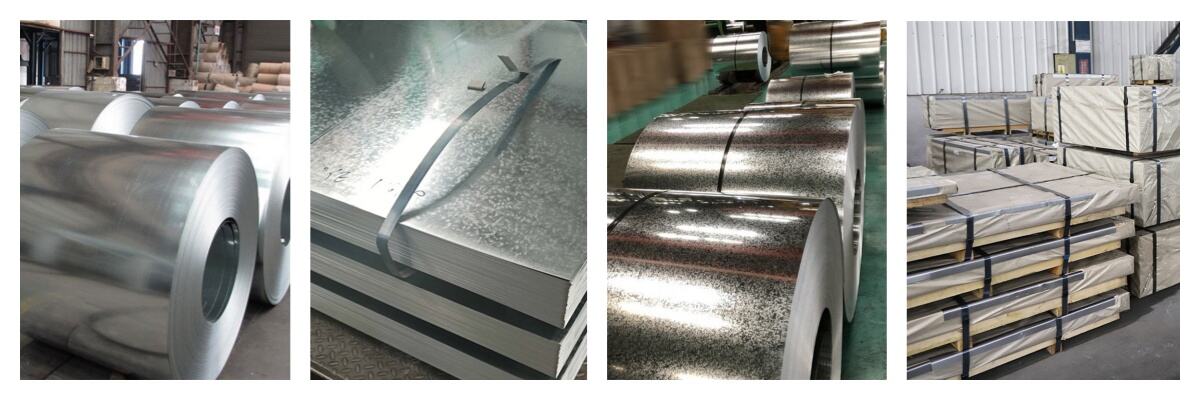

Sgcc stål er varmeed dip-galvaniseret stålplade og -lister, der opfylder JIS G3302 standard. Det har fremragende holdbarhed og korrosionsresistens. Tykkelsen af SGCC materialet ligger mellem 0,25 mm og 3,2 mm.

Første bogstav "S" i SGCC står for stål, mens "G" står for galvaniseret. Tredje bogstav "C" står for koldeformet stål, dvs. at basismaterialet er koldeformet stål, og fjerde bogstav "C" står for handelskvalitet.

Hvad Er SGCC?

SGCC ( varmeed dip-galvaniseret stålplade) henviser til en stålplade, der er belagt med et lag zink på overfladen af den kolde-rullede stålplade gennem en galvaniseringsproces. Den varme-dip galvaniseringsproces bruger høj temperatur for at kombinere zink med stålsubtratet for at danne et zinklag med god adhæsion, hvilket ikke kun forbedrer korrosionsmodstanden hos stålpladen, men også forbedrer dens styrke og skurværdsmodstand.

Produktionsprocessen for SGCC :

Produktionsprocessen for SGCC-stålplade er hovedsageligt opdelt i flere trin. Herunder følger en detaljeret beskrivelse af SGCC-produktionsprocessen.

Vælgning og forberedelse af råmaterialer: Produktionen af SGCC stålplade begynder med valget af højekvalitets koldrulleret stålbånd. Dette slag stålbånd består typisk af lavkarbonstål eller andre legemeståle, med gode plasticitet, bearbejdningsegenskaber og veldsigelighed. Ved vælger af materialer er det nødvendigt at sikre, at stålets kemiske sammensætning opfylder de tilsvarende standarder for at sikre dets gode mekaniske egenskaber og tilpasningsevne til efterfølgende bearbejdning.

Vælgning og forberedelse af råmaterialer: Produktionen af SGCC stålplade begynder med valget af højekvalitets koldrulleret stålbånd. Dette slag stålbånd består typisk af lavkarbonstål eller andre legemeståle, med gode plasticitet, bearbejdningsegenskaber og veldsigelighed. Ved vælger af materialer er det nødvendigt at sikre, at stålets kemiske sammensætning opfylder de tilsvarende standarder for at sikre dets gode mekaniske egenskaber og tilpasningsevne til efterfølgende bearbejdning.

Koldrulleringsprocessen: Det rå stålbånd presses til den ønskede tykkelse gennem en koldrulleringsproces. Denne proces dannes ved at føre stålbåndet igennem flere rullere. Denne proces gør stålbåndets overflade smooth, tykkelsen er ensartet, og dens styrke og hårdehed øges.

Koldrulleringsprocessen: Det rå stålbånd presses til den ønskede tykkelse gennem en koldrulleringsproces. Denne proces dannes ved at føre stålbåndet igennem flere rullere. Denne proces gør stålbåndets overflade smooth, tykkelsen er ensartet, og dens styrke og hårdehed øges.

Hed galvaniseringsproces: Efter koldrulning går stålbåndet ind i galvaniseringsbænken, og overfladen af stålbåndet bliver behandlet med højtempereret zinkvæske for at danne en zincskikkelse. Denne proces består i at behandle stålpladen gennem en smeltet zincbad. Zincets overflade vil reagere kemisk med stålpladen for at danne en zinc-jern alloylag, samtidig med at den opretholder zincskikkens renhed. Zincskikkens tykkelse er normalt 20-25 mikroner, men kan også justeres efter behov i visse tilfælde.

Hed galvaniseringsproces: Efter koldrulning går stålbåndet ind i galvaniseringsbænken, og overfladen af stålbåndet bliver behandlet med højtempereret zinkvæske for at danne en zincskikkelse. Denne proces består i at behandle stålpladen gennem en smeltet zincbad. Zincets overflade vil reagere kemisk med stålpladen for at danne en zinc-jern alloylag, samtidig med at den opretholder zincskikkens renhed. Zincskikkens tykkelse er normalt 20-25 mikroner, men kan også justeres efter behov i visse tilfælde.

Køling og skæring: Det hot-dip galvaniserede stålbånd vil gå igennem en kølebænk for hurtigt at senke temperaturen og sikre solidificeringen af zincskikkelsen. Efter kølingen vil stålbåndet blive skåret til den ønskede størrelse og gå ind i den endelige produktinspektions- og pakningsfase.

Køling og skæring: Det hot-dip galvaniserede stålbånd vil gå igennem en kølebænk for hurtigt at senke temperaturen og sikre solidificeringen af zincskikkelsen. Efter kølingen vil stålbåndet blive skåret til den ønskede størrelse og gå ind i den endelige produktinspektions- og pakningsfase.

Hovedegenskaber ved SGCC :

Korrosionsresistens: Overfladen af SGCC-stål er dækket med en lag zinc. Zinc-laget fungerer ikke kun som en fysisk barrier, men har også en selvhelede mekanisme. Når der opstår en lille skramme på overfladen, reagerer zincet med den omkringliggende luft for at danne en beskyttende film, der forhindre yderligere korrosion.

Korrosionsresistens: Overfladen af SGCC-stål er dækket med en lag zinc. Zinc-laget fungerer ikke kun som en fysisk barrier, men har også en selvhelede mekanisme. Når der opstår en lille skramme på overfladen, reagerer zincet med den omkringliggende luft for at danne en beskyttende film, der forhindre yderligere korrosion.

Høj mekanisk styrke: Gennem bearbejdning af koldrullet stålbånd forbedres stærken af pladen og den har god lastevne. Normalt ligger styrken af SGCC mellem 300MPa og 500MPa, hvilket kan opfylde kravene i de fleste anvendelser. SGCC med forskellige zincluderede tykkelse vil også påvirke styrken af stålpladen. Et tykkere zinc-lag kan gøre stålpladen lidt mere brølende, men det vil ikke påvirke de fleste af dets brugs egenskaber.

Høj mekanisk styrke: Gennem bearbejdning af koldrullet stålbånd forbedres stærken af pladen og den har god lastevne. Normalt ligger styrken af SGCC mellem 300MPa og 500MPa, hvilket kan opfylde kravene i de fleste anvendelser. SGCC med forskellige zincluderede tykkelse vil også påvirke styrken af stålpladen. Et tykkere zinc-lag kan gøre stålpladen lidt mere brølende, men det vil ikke påvirke de fleste af dets brugs egenskaber.

God bearbejdningsevne: SGCC stålplader viser god plasticit under bearbejdning og kan udsættes for forskellige formgivningsprocesser, herunder presformning, bøjning, strækning osv. Desuden er overfladen flad og uden defekter, egnet til malering og beklædning.

God bearbejdningsevne: SGCC stålplader viser god plasticit under bearbejdning og kan udsættes for forskellige formgivningsprocesser, herunder presformning, bøjning, strækning osv. Desuden er overfladen flad og uden defekter, egnet til malering og beklædning.

Jævn coatings: Galvaniseringsprocessen sikrer, at galvaniseringslagets tykkelse på overfladen af SGCC stål er jævn, hvilket yderligere forbedrer stålets beskyttelsesevne.

Jævn coatings: Galvaniseringsprocessen sikrer, at galvaniseringslagets tykkelse på overfladen af SGCC stål er jævn, hvilket yderligere forbedrer stålets beskyttelsesevne.

Varmebestandighed: SGCC stålplader har god varmebestandighed og kan normalt udholde en temperaturinterval på 200℃ til 300℃. Udenfor dette temperaturområde kan zinklaget begynde at oxidere, hvilket resulterer i en svækket korrosionsbeskyttelse.

Varmebestandighed: SGCC stålplader har god varmebestandighed og kan normalt udholde en temperaturinterval på 200℃ til 300℃. Udenfor dette temperaturområde kan zinklaget begynde at oxidere, hvilket resulterer i en svækket korrosionsbeskyttelse.

Anvendelsesområder for SGCC :

Som et materiale med gode egenskaber og bred anvendelse har SGCC været omfattende brugt i mange industrier.

Bygningsindustrien: tagdele, væggemænder, stålkonstruktioner og andre bygningsprojekter.

Bygningsindustrien: tagdele, væggemænder, stålkonstruktioner og andre bygningsprojekter.

Husholdningselektronikindustri: eksterne strukturelle dele af husholdningsapparater såsom køleskabe, vaskemaskiner, luftkonditioneringsskal, mikrobølgeovne osv.

Husholdningselektronikindustri: eksterne strukturelle dele af husholdningsapparater såsom køleskabe, vaskemaskiner, luftkonditioneringsskal, mikrobølgeovne osv.

Bilindustri: dele såsom bilkarosseri og chassisstruktur.

Bilindustri: dele såsom bilkarosseri og chassisstruktur.

Elektroniske produkter: TV-skaller, computerkasser, mobiltelefonskal osv.

Elektroniske produkter: TV-skaller, computerkasser, mobiltelefonskal osv.

Husdekoration: aluminiums dør- og vinduesrammer, indendørs og udendørs dekorationspaneler osv.

Husdekoration: aluminiums dør- og vinduesrammer, indendørs og udendørs dekorationspaneler osv.

Vi er en professionel stålprodusent. Hvis du har nogen behov, kan du kontakte os når som helst!

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )  info@steelgroups.com

info@steelgroups.com