316 stainless steel pipe belongs to austenitic stainless steel. This type of stainless steel is named after its microstructure, which is mainly composed of austenite phase (face-centered cubic crystal structure).

SS 316 pipe is an austenitic stainless steel, the main components of which include iron, chromium, nickel and molybdenum. It is widely used for its excellent corrosion resistance and high temperature performance in chloride environments.

316 stainless steel pipe contains chromium, which helps to form a passivation film on the metal surface. This film protects the metal from corrosion by preventing oxygen and water from contacting the underlying metal. The addition of molybdenum also enhances the corrosion resistance of 316 stainless steel tube.

What Are The Chemical Elements And Mechanical Properties Of 316 Stainless Steel Pipe?

Chemical elements:

The addition of molybdenum gives 316 stainless steel excellent resistance to pitting and crevice corrosion, especially in chloride environments.

|

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

|

316

|

≤0.08

|

≤2.0

|

≤0.75

|

≤0.045

|

≤0.030

|

16.0-18.0

|

2.0-3.0

|

10.0-14.0

|

≤0.10

|

Mechanical properties:

These mechanical properties give 316 ss pipe excellent stability and durability in high pressure and high temperature environments.

|

Material

|

Tensile Strength

|

Yield Strength

|

Elongation %, Min

|

|

Ksi (MPa), Min.

|

Ksi (MPa), Min.

|

|

|

316

|

75(515)

|

30(205)

|

35

|

What Are The Characteristics Of 316 Stainless Steel Pipe?

Corrosion resistance: 316 stainless steel tube has excellent corrosion resistance due to the 2-3% molybdenum element, especially in environments containing chloride ions, such as seawater, acidic and alkaline solutions in the chemical industry, etc.

Corrosion resistance: 316 stainless steel tube has excellent corrosion resistance due to the 2-3% molybdenum element, especially in environments containing chloride ions, such as seawater, acidic and alkaline solutions in the chemical industry, etc.

Mechanical properties: It has high tensile strength and yield strength, and has good ductility and toughness.

Mechanical properties: It has high tensile strength and yield strength, and has good ductility and toughness.

High temperature performance: 316 stainless steel has good oxidation resistance and strength at high temperatures, can maintain stable performance, and is suitable for high temperature environments.

High temperature performance: 316 stainless steel has good oxidation resistance and strength at high temperatures, can maintain stable performance, and is suitable for high temperature environments.

Machinability: 316 stainless steel pipe has good machinability and can be formed and processed by cold working, hot working, welding and other methods to meet different application requirements.

Machinability: 316 stainless steel pipe has good machinability and can be formed and processed by cold working, hot working, welding and other methods to meet different application requirements.

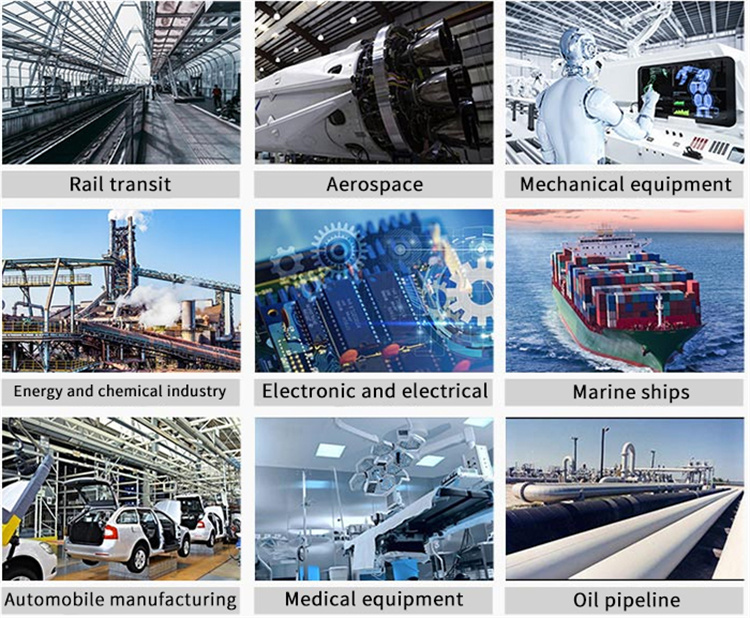

316 Stainless Steel Pipe Application Areas:

Chemical industry:

Chemical industry:

316 stainless steel pipe is mainly used in equipment manufacturing in the chemical industry, such as reactors, storage tanks, pipelines, etc., because of its strong corrosion resistance and ability to resist the erosion of various acid and alkali solutions.

Medical equipment:

Medical equipment:

316 stainless steel pipe is mainly used in medical equipment, such as surgical instruments, implants, etc., because of its good biocompatibility and corrosion resistance.

Food and Beverage Industry:

Food and Beverage Industry:

316 stainless steel pipes meet food safety standards due to their corrosion resistance, easy cleaning, and low bacterial growth. They are mainly used in dairy processing equipment, brewing equipment, etc.

Aerospace:

Aerospace:

316 stainless steel pipes are mainly used to manufacture high-strength, high-corrosion-resistant parts such as fuel pipelines, hydraulic systems, etc.

Construction and Decoration:

Construction and Decoration:

316 stainless steel pipes are mainly used to make stair handrails, exterior wall decoration, landscape engineering, etc.

Quality Inspection Of 316 Stainless Steel Pipes:

Physical performance inspection:

Physical performance inspection:

Physical performance inspection includes tensile testing, impact testing, hardness testing, etc., to evaluate the strength, toughness and hardness of 316 stainless steel pipes.

Chemical composition analysis:

Chemical composition analysis:

Chemical composition analysis uses equipment such as spectrometers and mass spectrometers to detect whether the composition of 316 stainless steel pipes meets standard requirements.

Nondestructive testing methods:

Nondestructive testing methods:

Nondestructive testing methods include ultrasonic testing, X-ray testing, etc., which can detect defects inside 316 stainless steel pipes and weld quality problems.

The inspection of stainless steel pipes is very important. Our factory will conduct quality inspection on the products before delivery. This is not only responsible to our customers, but also reflects our commitment to providing high-quality products.