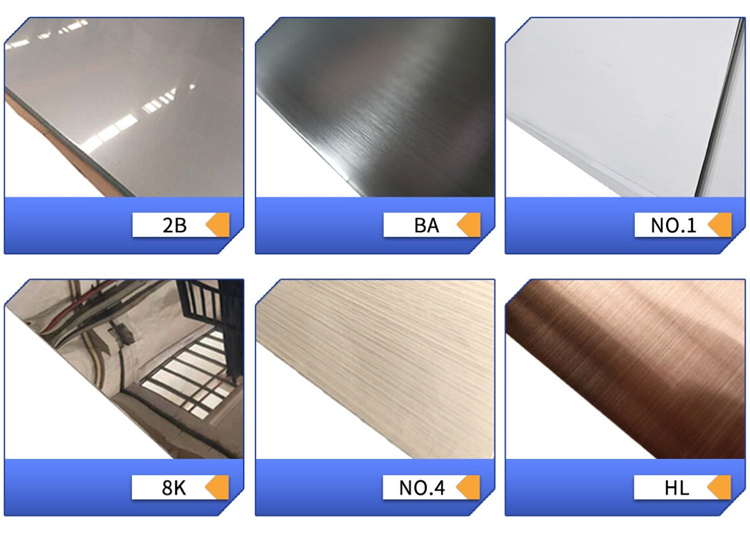

As a widely used material, the surface treatment process of stainless steel plates is crucial to the final performance and appearance of the product. Next, we will take a detailed look at several common surface treatment processes for stainless steel.

2B Surface Treatment:

2B surface treatment is the surface state obtained by cold-rolled stainless steel plates after heat treatment, pickling, and then light cold rolling. The surface obtained by this treatment method is relatively smooth and has a certain gloss, but not as bright as a mirror.

|

Surface Finish

|

Features

|

Application

|

|

2B

|

The 2B surface has a matte effect and a high surface finish, but still retains some slight rolling texture.

|

Building materials: used for curtain walls, roofs and door and window materials.

Home appliances: such as the shells of washing machines, refrigerators and microwave ovens.

Automobile manufacturing: used for automobile interior decoration and exhaust systems.

Food processing: manufacturing food-grade containers and equipment.

|

2B:

2B:

The 2B surface treatment process mainly includes the following steps:

Cold rolling: Stainless steel is rolled in a cold rolling mill to form a plate of a certain thickness.

Cold rolling: Stainless steel is rolled in a cold rolling mill to form a plate of a certain thickness.

Heat treatment: Annealing is performed to eliminate processing stress and improve the mechanical properties of stainless steel.

Heat treatment: Annealing is performed to eliminate processing stress and improve the mechanical properties of stainless steel.

Pickling: Use an acid solution to remove the surface oxide scale to make the surface cleaner.

Pickling: Use an acid solution to remove the surface oxide scale to make the surface cleaner.

Light cold rolling: Through light cold rolling treatment, a smooth surface is obtained and the plate reaches the required thickness.

Light cold rolling: Through light cold rolling treatment, a smooth surface is obtained and the plate reaches the required thickness.

BA Surface Treatment:

BA (Bright Annealed) surface treatment is the surface of stainless steel treated by bright annealing process. The surface of stainless steel after bright annealing is smooth and highly reflective, similar to the mirror effect.

|

Surface Finish

|

Features

|

Application

|

|

BA

|

BA surface is smooth and highly reflective, with a mirror-like effect, but compared with 8K mirror treatment, its surface is softer and the gloss is slightly weaker.

|

High-end home appliances: such as refrigerator panels and dishwasher interiors.

Kitchen equipment: high-end kitchenware, cookware and tableware.

Medical equipment: surgical instruments and equipment with a high level of hygiene.

Automotive decoration: interior decoration and decorative parts.

|

BA:

BA:

The key steps of BA surface treatment process include:

Cold rolling: initially rolling the stainless steel sheet to the required thickness.

Cold rolling: initially rolling the stainless steel sheet to the required thickness.

Bright annealing: annealing in a controlled atmosphere (usually hydrogen or nitrogen-hydrogen mixed gas) to keep the stainless steel surface bright and reduce the formation of oxide scale.

Bright annealing: annealing in a controlled atmosphere (usually hydrogen or nitrogen-hydrogen mixed gas) to keep the stainless steel surface bright and reduce the formation of oxide scale.

Leveling: After precise leveling, ensure the flatness and smoothness of the sheet.

Leveling: After precise leveling, ensure the flatness and smoothness of the sheet.

No.1 Surface Treatment:

No.1 surface is a stainless steel surface that has been hot-rolled, annealed and pickled. It is usually a thick plate with a rough and matte surface, but has good corrosion resistance and high-temperature oxidation resistance.

|

Surface Finish

|

Features

|

Application

|

|

No.1

|

No.1 surface is rough, usually grayish white, with obvious rolling texture and residual traces of oxide scale on the surface. In addition, the treated stainless steel is usually thicker.

|

Industrial equipment: such as boilers, pressure vessels and chemical equipment.

Building components: used for curtain walls, bridge structures, etc.

Heat-resistant equipment: furnace components and heat exchangers in high temperature environments.

|

No.1:

No.1:

No.1 surface treatment process usually includes the following steps:

Hot rolling: rolling the steel billet into a plate at high temperature.

Hot rolling: rolling the steel billet into a plate at high temperature.

Annealing: eliminate work hardening and improve the ductility and toughness of the material.

Annealing: eliminate work hardening and improve the ductility and toughness of the material.

Pickling: remove the oxide scale produced during hot rolling to make the surface clean.

Pickling: remove the oxide scale produced during hot rolling to make the surface clean.

8K Surface Treatment:

8K surface is a mirror-polished stainless steel surface with extremely high finish and reflectivity. It can reflect images like a mirror, so it is also called "mirror panel".

|

Surface Finish

|

Features

|

Application

|

|

8K

|

8K surface is extremely smooth and has a high reflectivity. The surface is as shiny as a mirror and can clearly reflect images.

|

Architectural decoration: used for indoor and outdoor decoration of high-end buildings, such as elevator panels, handrails and curtain walls.

Home appliance housing: the housing of high-end refrigerators, ovens and other home appliances.

Artwork and sculpture: used to make modern artwork and sculpture to enhance the visual effect.

Automotive decorative parts: high-gloss parts for interior and exterior decoration.

|

8K:

8K:

The steps of 8K surface treatment process are as follows:

Grinding: Use sanding belts or grinding discs of different particle sizes to gradually grind the stainless steel surface to remove rough surfaces and defects.

Grinding: Use sanding belts or grinding discs of different particle sizes to gradually grind the stainless steel surface to remove rough surfaces and defects.

Polishing: Use polishing paste and polishing wheels to further treat the surface until a mirror effect is achieved.

Polishing: Use polishing paste and polishing wheels to further treat the surface until a mirror effect is achieved.

Cleaning: After polishing, clean thoroughly to remove the polishing agent and grinding chips remaining on the surface.

Cleaning: After polishing, clean thoroughly to remove the polishing agent and grinding chips remaining on the surface.

No.4 Surface Treatment:

No.4 surface treatment, also known as brushed treatment, is a surface with a unique texture formed by directional grinding of the stainless steel surface using abrasive belts or sandpaper. The surface after this treatment has a soft luster and a silky texture.

|

Surface Finish

|

Features

|

Application

|

|

No.4

|

No.4 surface has a uniform brushed texture and moderate gloss, and has a delicate touch. Compared with 8K surface, No.4 surface is less likely to leave fingerprints and stains and is easy to clean.

|

Architectural decoration: widely used in interior and exterior wall decorative panels, elevator panels and railings.

Home appliances and kitchenware: such as refrigerator door panels, dishwasher panels and high-end kitchenware.

Furniture: Decorative panels and components for modern style furniture.

Automotive manufacturing: Used for interior decorative parts such as dashboards and door trims.

|

No.4:

No.4:

The key steps of No.4 surface treatment include:

Grinding: Use a medium-grained abrasive belt (usually 150-180 mesh) to grind the stainless steel surface in a straight or cross direction.

Grinding: Use a medium-grained abrasive belt (usually 150-180 mesh) to grind the stainless steel surface in a straight or cross direction.

Deburring: Deburring is required after grinding to ensure a smooth and burr-free surface.

Deburring: Deburring is required after grinding to ensure a smooth and burr-free surface.

Cleaning: Remove debris and dirt generated during the grinding process.

Cleaning: Remove debris and dirt generated during the grinding process.

HL Surface Treatment:

HL (Hairline) surface treatment is to form a slender, continuous filamentous texture on the stainless steel surface through long linear grinding, giving it a unique decorative effect.

|

Surface Finish

|

Features

|

Application

|

|

HL

|

HL surface has a continuous and fine brushed texture, low gloss and unique texture. Its texture is usually long and straight, and the surface is relatively flat. Similar to No.4 surface, HL surface has good fingerprint and anti-fouling properties.

|

Architectural decoration: such as facade decoration, interior wall decoration, stair handrails, etc.

Home appliances: Especially suitable for panels of home appliances such as refrigerators, washing machines, ovens, etc.

Elevator panels: HL surface is widely used for decorative panels inside and outside elevators because it is durable and not easy to leave fingerprints.

Furniture: Used for surface decoration of modern style furniture, such as desktops, cabinet panels, etc.

Sanitary ware: Used for high-end wash basins, bathroom accessories, etc.

|

HL :

HL :

The steps of HL surface treatment are as follows:

Coarse grinding: Use a coarser sanding belt to perform preliminary grinding on the stainless steel surface to form a basic texture.

Coarse grinding: Use a coarser sanding belt to perform preliminary grinding on the stainless steel surface to form a basic texture.

Fine grinding: Use a finer sanding belt for fine grinding to make the surface texture more delicate and uniform.

Fine grinding: Use a finer sanding belt for fine grinding to make the surface texture more delicate and uniform.

Cleaning and deburring: Ensure the surface is clean and burr-free, and enhance the surface finish and visual effect.

Cleaning and deburring: Ensure the surface is clean and burr-free, and enhance the surface finish and visual effect.

Contact Us:

Email:info@steelgroups.com

Whatsapp:+86 17611015797