- Panimula

- Kaugnay na Mga Produkto

Paglalarawan:

Paglalarawan:

Ang 'NM' sa NM600 ay tumutukoy sa plato na resistant sa pagpapawis, ang unang titik ng 'Nai' at 'Mo', at ang 600 ay ang valor ng Brinell hardness HB. Ang klase ay mas mataas kaysa sa NM500, NM450, NM400, at NM360.

Patakaran ng Implementasyon ng NM600: implementasyon ng korporatibong patakaran Q/XGJ166-2009

Katayuan ng Pagpapadala: pagpipisan at pagpaparamdam (pagpipisan + pagpaparamdam)

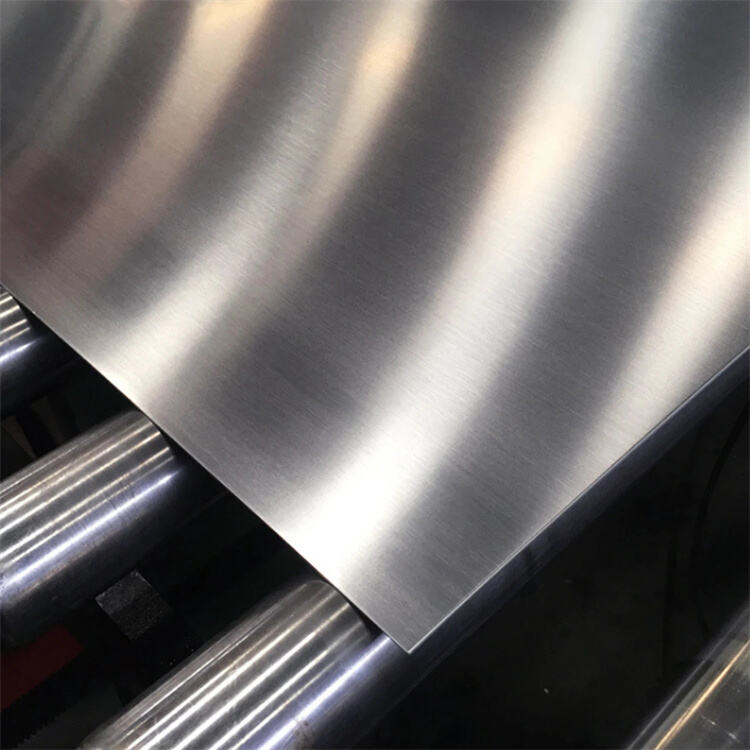

Mga Espesipikasyon:

Mga Espesipikasyon:

|

Pangalan ng Produkto |

Plato ng Matatag na Bakal |

|

Baitang ng Steel |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Kapal |

2mm-300mm |

|

Lapad |

500-2500mm |

|

Habà |

1000mm-12000mm o ayon sa espesyal na hiling ng kustomer |

|

Tolerance |

Lakas: +/-0.02mm, Lapad:+/-2mm |

|

Oras ng Pagpapadala |

7-15 araw ng trabaho pagkatapos makatanggap ng 30% pabaya |

|

Sertipikasyon |

BV SGS CE TUV |

|

PACKAGE |

Bundled with steel strip, Konteyner shipping |

Pag-uulit ng Standard ng NM600 Steel:

|

Baitang ng Steel |

SSAB |

ThyssenKrupp |

JFE |

DILLIDUR |

Ruukki |

|

NM600 |

HARDOX600 |

XAR600 |

- |

600V |

Raex600 |

Plato ng Asero na Resistente sa Pag-aasar na NM600 Nilalaman ng mga Elementong Kimiko (%)

|

Komponente |

C |

Si |

Mn |

P |

S |

CR |

Ni |

Mo |

Ti |

B |

AL |

|

Pinakamababang halaga |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Pinakamataas na halaga |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

NM600 Pagsasara Mekanikal na Katangian ng Platahang Aserong Resistenteng sa Pagsasara:

|

Kapal |

Tensile Strength |

Bilis ng Pagpapahaba o Pag-estensya |

Katigasan |

|

t≤60 |

- |

- |

Kadakilaan ng Kabuhayan: 570~640HBW |

Mga Kahinaan ng NM600:

Mataas na kakapusan sa paglaban: Ang halaga ng carbon sa kimikal na komposisyon ng alagang katutubong layer ay 4-5%, at ang halaga ng kromium ay mataas hanggang 25-30%. Umuunlad sa bahagyang straktura ng Cr7C3 carbide hanggang higit sa 50%, ang makro kadakilaan ay HRC56-62, at ang kadakilaan ng kromium carbide ay HV1400-1800. Dahil ang mga carbide ay kinabibilangan nang patagpatalian sa direksyon ng pagiging sikat, kahit na pinag-uusapan ito sa mga anyo ng alagang may parehong komposisyon at kadakilaan, ang kakapusan sa pagiging sikat ay higit sa dalawin.

Mataas na kakapusan sa paglaban: Ang halaga ng carbon sa kimikal na komposisyon ng alagang katutubong layer ay 4-5%, at ang halaga ng kromium ay mataas hanggang 25-30%. Umuunlad sa bahagyang straktura ng Cr7C3 carbide hanggang higit sa 50%, ang makro kadakilaan ay HRC56-62, at ang kadakilaan ng kromium carbide ay HV1400-1800. Dahil ang mga carbide ay kinabibilangan nang patagpatalian sa direksyon ng pagiging sikat, kahit na pinag-uusapan ito sa mga anyo ng alagang may parehong komposisyon at kadakilaan, ang kakapusan sa pagiging sikat ay higit sa dalawin.

Mabuting resistensya sa impact: Ang substrate ng plato na kompositong tuwid na may katatagan ay isang matigas na material tulad ng mababang karbon na bakal o mababang alloy, na nagpapakita ng kahinaan ng bimetal. Ang antas ng pagkawear ay nakakahambing sa pagkawear ng medium ng pagkawear, at ang substrate ang nagdadala sa load ng medium, kaya't ito ay may mabuting resistensya sa impact. Maaari itong tiisin ang impact at pagkawear ng mataas na drop hoppers sa mga sistema ng pagdala ng materiales.

Mabuting resistensya sa impact: Ang substrate ng plato na kompositong tuwid na may katatagan ay isang matigas na material tulad ng mababang karbon na bakal o mababang alloy, na nagpapakita ng kahinaan ng bimetal. Ang antas ng pagkawear ay nakakahambing sa pagkawear ng medium ng pagkawear, at ang substrate ang nagdadala sa load ng medium, kaya't ito ay may mabuting resistensya sa impact. Maaari itong tiisin ang impact at pagkawear ng mataas na drop hoppers sa mga sistema ng pagdala ng materiales.

Mabuting resistensya sa init: Inirerekomenda ang alloy wear-resistant layer na gamitin sa mga kondisyon ng trabaho na ≤600. Kung idinagdag ang vanadium, molybdenum at iba pang mga alloy sa alloy wear-resistant layer, maaaring tiisin ito ang mataas na temperatura ng pagwawear na ≤800. Ang inirerekomendang temperatura ng operasyon ay sumusunod: Inirerekomenda ang karbon na ordinaryong substrates na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 380; Low alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, atbp.) substrates inirerekomenda na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 540; Heat-resistant stainless steel substrates inirerekomenda na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 800.

Mabuting resistensya sa init: Inirerekomenda ang alloy wear-resistant layer na gamitin sa mga kondisyon ng trabaho na ≤600. Kung idinagdag ang vanadium, molybdenum at iba pang mga alloy sa alloy wear-resistant layer, maaaring tiisin ito ang mataas na temperatura ng pagwawear na ≤800. Ang inirerekomendang temperatura ng operasyon ay sumusunod: Inirerekomenda ang karbon na ordinaryong substrates na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 380; Low alloy heat-resistant steel plate (15CrMo, 12Cr1MOV, atbp.) substrates inirerekomenda na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 540; Heat-resistant stainless steel substrates inirerekomenda na gamitin sa mga kondisyon ng trabaho na hindi mas mataas kaysa 800.

Mga aplikasyon:

Mga aplikasyon:

Ang NM600 ay madalas na ginagamit sa metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and tiles at iba pang industriya.

Pakikipag-Ilagay ng Produkto:

Pakikipag-Ilagay ng Produkto:

Gumagamit kami ng pinakaligtas at pinakaepektibong paraan ng pagsasaalang-alang para sa lahat ng uri ng pagpapadala.

FAQ:

FAQ:

1.Q: Ilang oras maaari maghatid?

A: Para sa mga produktong may stock, ipapadala ang mga shipment sa loob ng 5-7 araw matapos tumanggap ng deposito; para sa mga produktong kailanganan ng bagong produksyon para sa pangkaraniwang materiales, karaniwan na ipinapadala ang mga shipment sa loob ng 10-15 araw; para sa mga produktong kailanganan ng bagong produksyon para sa espesyal at madaling malangis na mga material, karaniwan ay kinakailangan 20-30 araw upang gumawa ng paghahatid.

2.Q: Maaari ba akong bisitahin ang inyong fabrica?

A: Sigurado, mabibigyan ka ng welkam sa pagsisita sa aming fabrica kahit kailan.

3.Q: Saan kayo nakatira?

A: Nasa Anyang sa lalawigan ng Henan.

4.Q: Anong mga sertipiko ang mayroon ang inyong mga produkto?

A: Mayroon kami ISO 9001, BV, SGS, CE, TUV at iba pang mga sertipikasyon.

5.Q: Ano ang mga kondisyon ng pagbabayad ninyo?

A: 30% T/T bayad nauna, 70% T/T balanse loob ng 5 araw matapos ang kopya ng B/L, 100%. Irrevocable L/C sa paningin, 100% Irrevocable L/C matapos tumanggap ng B/L 30-120 araw, O/A.

Tag:

NM600, mga Tagapagtatag ng Tsina ng Steel Sheet na Resistent sa Abrasiyon, Mga Tagapaghanda, Pabrika, NM300Wear Resistant SteelSheet, NM360Wear Resistant SteelSheet, NM500Wear Resistant SteelSheet, Mataas na Resistensya sa Pagmamalaki at Mataas na Katigasan, Mataas na Kalidad, NM600 Wear Resistant Steel Plate ,NM300TP ,NM400 ,NM400E ,Nm450 ,NM450E ,NM500 ,NM500E