- panimula

- Kaugnay na Mga Produkto

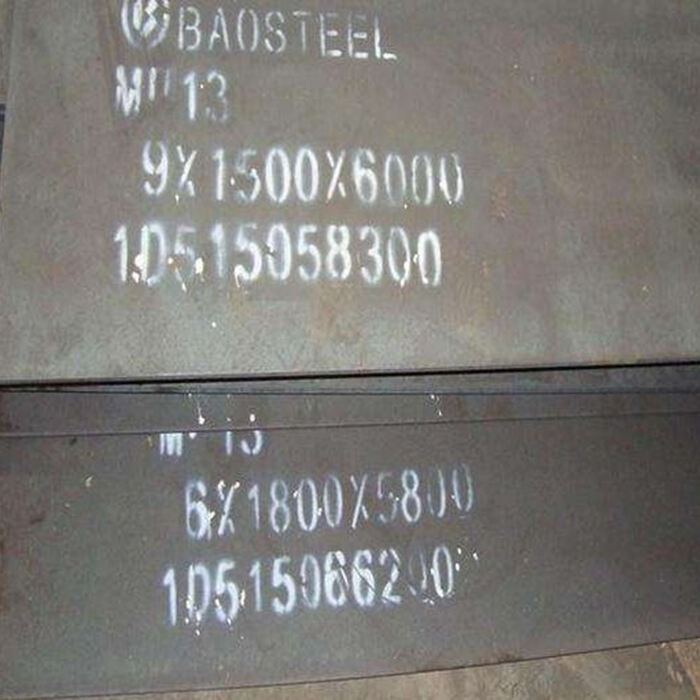

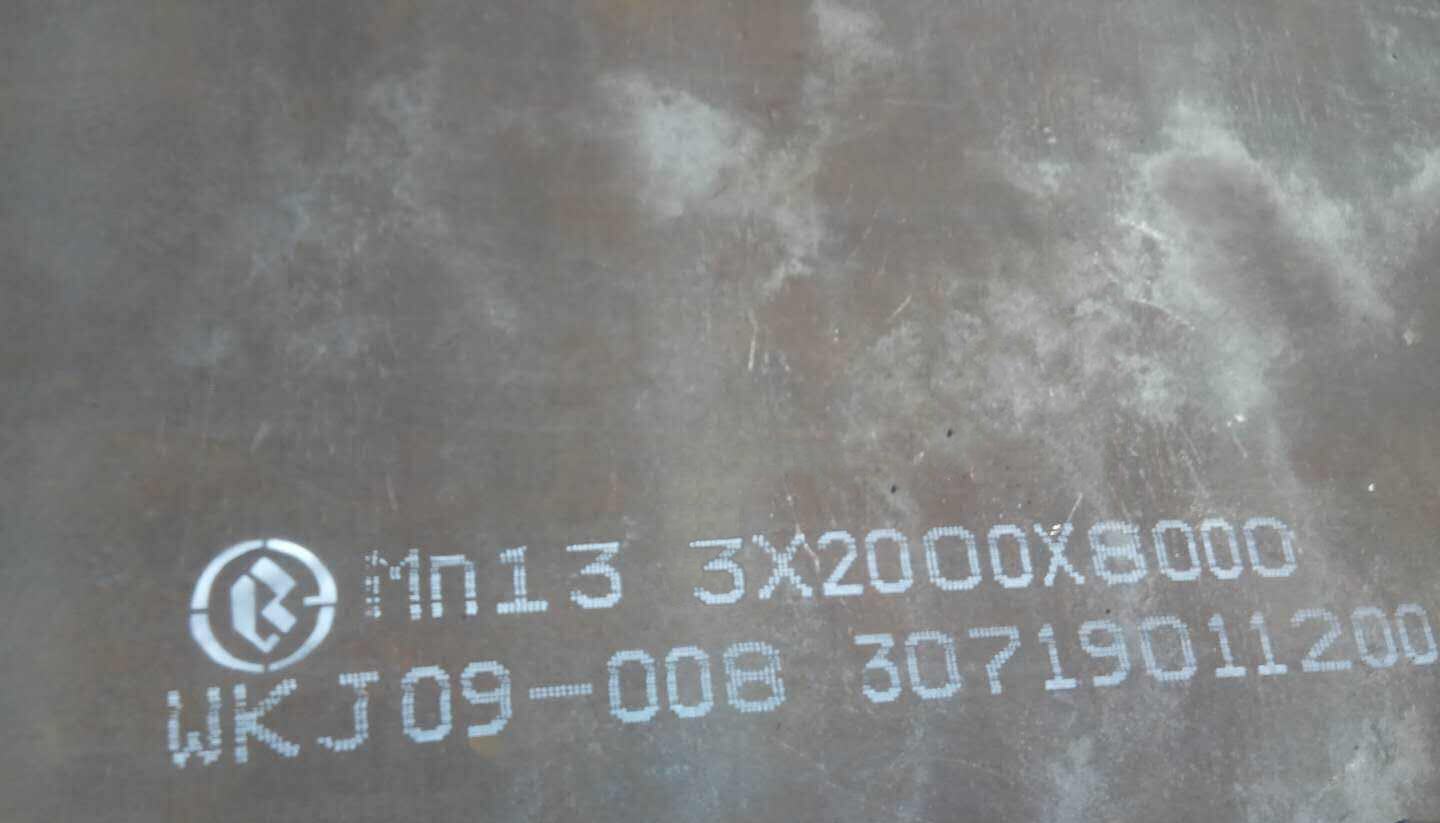

Paglalarawan:

Paglalarawan:

Ang Mn13 ay pili bilang materyales na nakakahiwa na maaaring magresista sa malakas na pagbisig, mataas na presyong paghiwa ng materyales, atbp. Mayroon itong katangian ng pagiging hardening kapag ginamit na hindi maaaring pantayin ng iba pang mga materyales na nakakahiwa. Sa ilalim ng aksyon ng malaking presyo ng loheng o malaking kontak na stress, ang ibabaw ng plato ng bakal ay gumagamit ng hardening, at ang karaniwang hardiness ng ibabaw ay mabilis na tumataas mula sa HB200 hanggang sa itaas pa ng HB500, kung kaya't naglilikha ng isang mataas na antas ng napakahihiwang lapis, habang patuloy ang panloob na austenite ng plato ng bakal na may mabuting resiliensiya sa pagbisig.

Mayroong dalawang katangian ang high manganese steel:

1. Hinigit-kumikita ang panlabas na impact load, ang higit na mataas ang resistance sa paghiwa ng kanilang sariling ibabaw na lapis;

2. Habang pinapatalsik ang lapis ng hardening ng ibabaw, isang bagong hardening layer ay patuloy na gagawa.

Ang mga espesyal na katangian ng tulayang mabango ay kaya ng gawin ang mga komponente na antas ng pagmamalabis na makakapagtagubilin sa malaking oras na pagmamalabis ng mga material na may mataas na impacto. Matagal nang madalas itong ginagamit sa mekanikal na kagamitan tulad ng metallurgy, mining, building materials, railways, electricity, at coal.

Mga Espesipikasyon:

Mga Espesipikasyon:

|

Item |

Mn13 |

|

Lapad |

1000 hanggang 3000mm |

|

Standard Grade |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400,; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

TEKNOLOHIKONG PROSES |

kinontrol na paggulong, mainit na tinatahak, normalizing, tempering, annealing, quenching, N+T, Q+T |

|

Kapal |

2 hanggang 300mm |

|

Ibabaw |

linis, pagsabog, paghuhula, at pagpinta |

|

Habà |

1000 hanggang 12000mm |

Kakatumbas na Klase ng Mn13 :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Kimikal na Anyo ng Mn13:

|

Baitang |

C |

si |

Mn |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11.0~14.0 |

≤0.035 |

≤0.030 |

Mga Propedad Mekanikal ng Mn13:

|

Baitang |

Lakas ng Tensile(MPa) |

Ang pag-iilaw (%) |

Pagpoproseso sa Pagpapalo (20℃) |

Saguting Halaga ng Karaniwang Hardness (HB) |

Halaga ng Hardness Matapos ang Paggawa ng Hardening (HB) |

Malamig na Pagbubuwis (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90(J) |

200-250 |

> 300 |

Kwalipikado |

Mga aplikasyon:

Mga aplikasyon:

Ang Mn13 ay madalas gamitin upang gawing mga ngipin ng sapa ng excavator, rolling wall at crushing wall ng mga cone crusher, fork plates ng jaw crushers, lining plates ng ball mills, railway switches, plate hammers, hammer heads, etc.

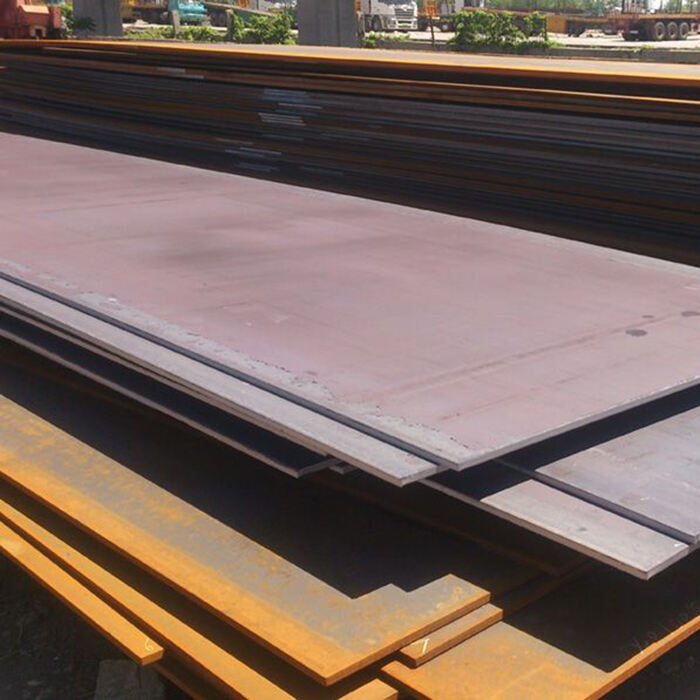

Pakikipag-Ilagay ng Produkto:

Pakikipag-Ilagay ng Produkto:

Gumagamit kami ng pinakaligtas at pinakaepektibong paraan ng pagsasaalang-alang para sa lahat ng uri ng pagpapadala.

FAQ:

FAQ:

1.Q: Ilang oras maaari maghatid?

A: Para sa mga produktong may stock, ipapadala ang mga shipment sa loob ng 5-7 araw matapos tumanggap ng deposito; para sa mga produktong kailanganan ng bagong produksyon para sa pangkaraniwang materiales, karaniwan na ipinapadala ang mga shipment sa loob ng 10-15 araw; para sa mga produktong kailanganan ng bagong produksyon para sa espesyal at madaling malangis na mga material, karaniwan ay kinakailangan 20-30 araw upang gumawa ng paghahatid.

2.Q: Maaari ba akong bisitahin ang inyong fabrica?

A: Sigurado, mabibigyan ka ng welkam sa pagsisita sa aming fabrica kahit kailan.

3.Q: Saan kayo nakatira?

A: Nasa Anyang sa lalawigan ng Henan.

4.Q: Anong mga sertipiko ang mayroon ang inyong mga produkto?

A: Mayroon kami ISO 9001, BV, SGS, CE, TUV at iba pang mga sertipikasyon.

5.Q: Ano ang mga kondisyon ng pagbabayad ninyo?

A: 30% T/T bayad nauna, 70% T/T balanse loob ng 5 araw matapos ang kopya ng B/L, 100%. Irrevocable L/C sa paningin, 100% Irrevocable L/C matapos tumanggap ng B/L 30-120 araw, O/A.

Tag:

Mn13, Tsina High Mn Wear-Resistant Steel Manufacturers, Mga Supplier, Factory, Wear-Corrosion-Resistant Steel, Mataas na Klase Hardened at Tempered Wear-Resistant Steel, Mataas na Ductility Brittle Crack Arrest Wear-Resistant Steel, Super Wear-Resistant Steel, Mataas na Temperatura at Wear Resistant Steel, High Mn Wear-Resistant Steel, Low Yield Ratio Wear-Resistant Steel