Lodeňský ocelový plech je dôležitou súčasťou lodí. Drží plavidlo pevné a bráni mu v poškodení, keď plavia cez nepríznivé more. Tu sa budeme zaoberať diskusiou o tom, aké ocelové plechy sa používajú na lode, ich vlastnosti a ako vybrať správny ocelový plech pre loď. Existuje mnoho typov oceľov prispôsobených rôznym podmienkam, ale väčšina z nich je vysokokvalitná námorná oceľ. Čo je výstavba lodi? A ktoré operatívne zariadenia sa použijú počas stavby!!

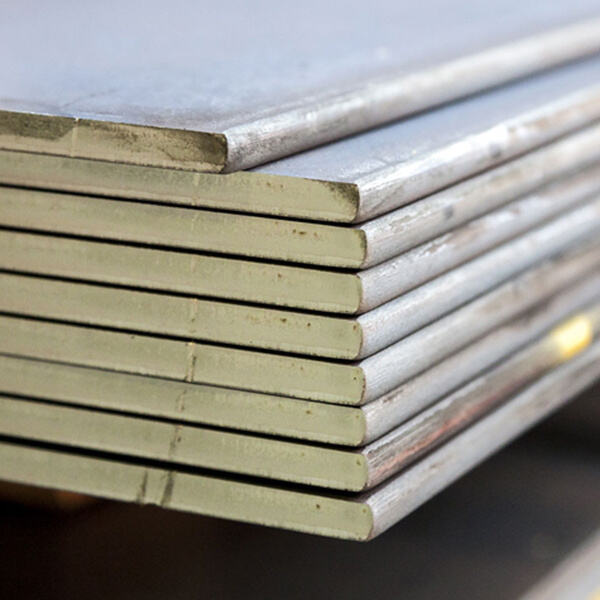

Existujú oceánske ocele, ktoré boli vyvinuté tak, aby boli pevné a odolné. Presne to drží lodie spolu a bráni ich v tom, aby sa zrútili v oceáne. Najlepšia oceánska ocel je tiež schopná prestať pred akoukoľvek počasím, ako sú silné vetra a těžké moře. V tomto prípade pomáha táto kapacita štrukturálnej ocele udržať loď celkom a nezlomiť sa na kusy počas plavby. Lode sú postavené z dobrých ocelových plátov, aby sa zabezpečila pevnosť ich trupov a mohli bezpečne prepravovať ľudí a náklad cez dlhé vzdialenosti.

Nadživotnosť oceánskych oceleových plátov pre dopravu cez vodu závisí od mnohých charakteristik. Takýto plát musí byť hrubý a vydržiavý, aby uniesol náklady lodí so zaobľenie, ako aj tovar alebo dodacie pristroje. Za touto hrúbkou je špeciálne dôležité, pretože umožňuje lode nést také ťažké náklady bez lámania alebo ohýbania. Oceľ je odolná pred koroziou, osobitne s morskou vodou, v ktorej sa korózia môže postupne poškodzovať plát. Musí prežiť nie len záťaž každého zdvihnutia, ale aj vařiaci slnečný svetel alebo mrznúcu tmavosť a kompresiu a expanziu spôsobenú pobytovaním na mori.

Takže, ako vybrať vhodnú oceánsku oceleovú dosku pre plavidlo? Hrúbka dosky je kľúčovou úvahou. Jasné je, že hrúbka bude rôzna, tušší alebo tenšia, podľa toho, či ide o plne naložené plavidlo alebo iba o jeho vonkajšiu oceleovú konštrukciu. Tuššie dosky sú potrebné pre bezpečnosť pri väčších lodiach alebo pri väčšom nákladí prevezenom lodou. Tiež hodnota skladby oceleovej dosky je niečím, čo stojí za úvahu. Pretože rôzne ocele majú rôzne stupne pevnosti a vlastnosti, čo znamená, že sa používajú na rôznych lodoch v ich príslušných prostrediah. Dôležité je pečlivo určiť stupeň ocele, pretože veľmi vplyva na bezpečnosť a efektívnosť priplávaní na mori.

Jednoducho musíte dbať na svoju oceánsku oceleovú dosku, aby ste ju mohli používať čo najdlhšiu dobu. Existujú niekoľko jednoduchých spôsobov, ako to urobiť, napríklad jej natretie špeciálnym protikorózovým farbou. Táto farba tiež slúži ako ochranná vrstva pre oceľ pred rézom a poškodením spôsobeným vystavením solnej vode pri kontakte s kyslíkom. Okrem toho, ak sa oceľová doska poškrábe alebo deformuje (alebo sa na nej objavia rézne skvrny), je čas tieto komponenty nahraďovať co najskôr. Keď zaznamenáte akékoľvek problémy, je veľmi dôležité ich okamžite opraviť predtým, než sa poškodenie zväčší. Pravidelná údržba je kľúčom k tomu, aby sa plavidlo zostalo bezpečné a spoľahlivé, schopné vykonať mnoho cest bez nehody alebo problémov.

Výroba ocele na lodeňské pláty prebieha pod striktnymi pravidlami a smernicami. Existujú špeciálne požiadavky, ktoré musia byť splnené, aby bola oceľ pevná, spoľahlivá a bezpečná pri použití v námornom dopravníku. Kvalita a trieda materiálu tejto ocele musí spĺňať konkrétne normy, rovnako ako jej procesy výroby. Inspekciu prechádzajú všetky fázy výrobného procesu, aby sa zabezpečilo, že nie je pozorovaná žiadna bezpečnostná hrozba týkajúca sa týchto plechov.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Zásady ochrany osobných údajov