Pri nákupi alebo používaní nerezová oceľ je dôležité vedieť, ako identifikovať ich kvalitu. Nerez existuje vo veľkom množstve druhov a ich kvalita sa od seba výrazne líši, takže správne posudzovanie kvality nerezu vám môže pomôcť vyhnúť sa nákupu inferiorného materiálu, čím zabezpečíte výkonnosť a životnosť konečného produktu.

1. Skontrolujte stupeň nerezu

Rôzne stupne nerezu majú v dôsledku rozdielov v sústave a štruktúre významné rozdiely v odolnosti pred koróziou, sily a zpracovateľnosti.

nerezová oceľ 304 : Je to najbežnejší austenitný neraz, obsahujúci 18 % hromu a 8 % niklu, s dobrým odolstvom pred koróziou a zpracovateľnosťou. Široko sa používa v domácnostných kuchynských potrebných, zariadení na spracovanie potravín atď.

nerezová oceľ 304 : Je to najbežnejší austenitný neraz, obsahujúci 18 % hromu a 8 % niklu, s dobrým odolstvom pred koróziou a zpracovateľnosťou. Široko sa používa v domácnostných kuchynských potrebných, zariadení na spracovanie potravín atď.

nerdzavieľo 316 : Je odolnejší pred koroziou ako 304 a je osobitne vhodný pre morské prostredia alebo prostredia s chloridmi. Obsahuje molibdén (2-3%), čo významne zvyšuje jeho schopnosť odolávať korozií z dôvodu prítomnosti chloridov.

nerdzavieľo 316 : Je odolnejší pred koroziou ako 304 a je osobitne vhodný pre morské prostredia alebo prostredia s chloridmi. Obsahuje molibdén (2-3%), čo významne zvyšuje jeho schopnosť odolávať korozií z dôvodu prítomnosti chloridov.

Nerez 430: Ferritová nerez, obsahuje menej niklu, má vyššiu tvrdość, ale horšiu odolnosť pred koroziou a používa sa obvykle v aplikáciách, kde nie je potrebná odolnosť pred koroziou.

Nerez 430: Ferritová nerez, obsahuje menej niklu, má vyššiu tvrdość, ale horšiu odolnosť pred koroziou a používa sa obvykle v aplikáciách, kde nie je potrebná odolnosť pred koroziou.

Prečo je trieda dôležitá?

Rôzne triedy nerézu obsahujú rôzne ligatúry, ako je hrom, nikol, molibdén atď., ktoré dodajú nerézu rôzne vlastnosti. Napríklad nerez 304 má dobrú odolnosť pred koroziou v bežných prostrediach a je vhodný na kuchynské nádobí a lekársky zariadenia; zatiaľ nerez 316 je vhodný pre morské prostredia alebo iné náročné prostredia s chloridmi, pretože obsahuje molibdén.

Ako identifikovať triedu?

V niektorých prípadoch výrobci uvedú stupeň na produkte alebo obaly, čo je rýchly spôsob identifikácie.

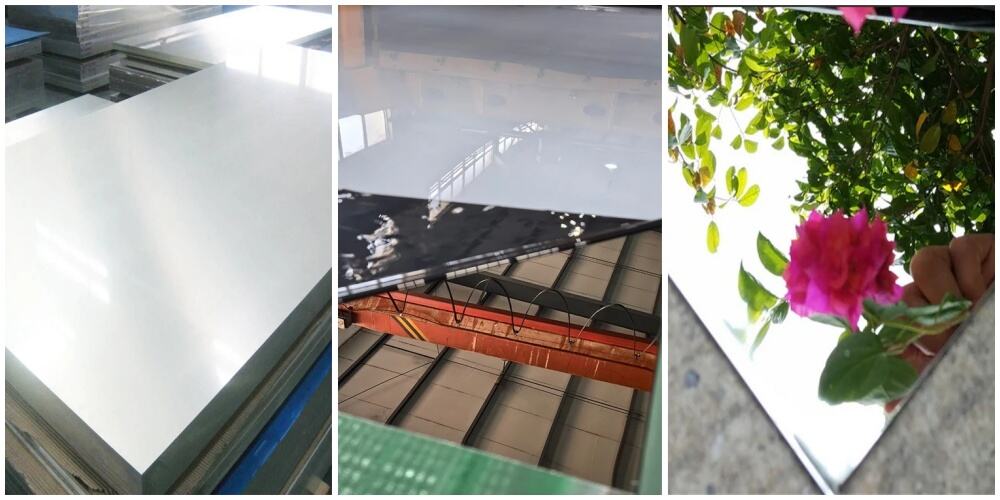

2. Skontrolujte povrchové dokončenie

Kvalitná nerdzavacia ocel by mala mať roviny a hladké povrchy bez žiadnych zrejmých škrábancov, defektov alebo iných povrchových chýb.

Metódy úpravy povrchu nerdzavacej ocele:

2B: Bežná studená valcová úprava povrchu nerdzavacej ocele, vhodná pre väčšinu priemyselných aplikácií. Je hladká, ale relatívne matná.

2B: Bežná studená valcová úprava povrchu nerdzavacej ocele, vhodná pre väčšinu priemyselných aplikácií. Je hladká, ale relatívne matná.

BA (zrkadlový lesk): Povrch má vysokú jasnosť a bežne sa používa v aplikáciách, ktoré vyžadujú pekný vzhľad, ako sú nádobky, architektonické výzdoby atď.

BA (zrkadlový lesk): Povrch má vysokú jasnosť a bežne sa používa v aplikáciách, ktoré vyžadujú pekný vzhľad, ako sú nádobky, architektonické výzdoby atď.

8K (zrkadlový lesk): Má veľmi jasný povrch, hladký ako zrkadlo, vhodný pre vysoko kvalitné výzdoby.

8K (zrkadlový lesk): Má veľmi jasný povrch, hladký ako zrkadlo, vhodný pre vysoko kvalitné výzdoby.

Ako hodnotiť kvalitu povrchu?

Skontrolujte, či je povrch rovnomerný a bez škrábancov, puchýri alebo iných defektov. Nerdzavacia ocel slabejších kvalít často má zrejmé chyby alebo skvrny na povrchu, čo ovplyvňuje jej vzhľad a životnosť.

3. Magnetický test

Magnetický test vám môže pomôcť počiatočne identifikovať typ nerdzového ocele, predovšetkým rozlišovať medzi austenitnou, ferritnou a martenzitnou nerdzovou oceľou. Rôzne typy nerdzových ocelí reagujú inak na magnety:

Ako vykonať magnetický test?

Použite malý magnet blízko povrchu nerdzovej ocele.

Použite malý magnet blízko povrchu nerdzovej ocele.

Ak sa magnet prilne, nerdzová oceľ je najpravdepodobnejšie ferritná alebo martenzitná.

Ak sa magnet prilne, nerdzová oceľ je najpravdepodobnejšie ferritná alebo martenzitná.

Ak sa magnet neprilne, nerdzová oceľ je austenitná.

Ak sa magnet neprilne, nerdzová oceľ je austenitná.

Faktory, ktoré treba zvážiť:

Hoci austenitná nerdzová oceľ je všeobecne ne-magnetická, niektorá magnetizácia môže byť indukována počas studenej deformácie (ako tiahnutie, razenie atď.). Preto môžeme magnetický test použiť len ako nástroj pre počiatočné identifikovanie a nemôže sa používať ako absolútne kritérium.

4. Overte hrúbku a toleranciu

Hrúbka a tolerancia nerdzového ocele sú dôležité faktory, ktoré ovplyvňujú jej výkon pri používaní. Obzvlášť pre aplikácie, ktoré musia niesť záťaže, je presná hrúbka a veľkosť nevyhnutné.

Ako merať hrúbku?

Použite správne nástroje na mieru hrubky listov nerdzového ocele. Uistite sa, že zmieraná hrúbka vyhovuje štandardom produktu alebo návrhovým požiadavkám.

Vyberte správne nástroje: Najčastejšie používané nástroje na meranie hrubky zahŕňajú štyriatka a mikrometre. Hrúbku tenkých plátov obvykle meriame pomocou mikrometra, zatiaľ čo hrubšie materiály sa obvykle merajú štyriatkami.

Vyberte správne nástroje: Najčastejšie používané nástroje na meranie hrubky zahŕňajú štyriatka a mikrometre. Hrúbku tenkých plátov obvykle meriame pomocou mikrometra, zatiaľ čo hrubšie materiály sa obvykle merajú štyriatkami.

Vyčistite povrch: Pred meraním je potrebné zabezpečiť, aby bol meraný povrch nerdzového plätu čistý a voľný od tukov, prachu alebo iného smetu.

Vyčistite povrch: Pred meraním je potrebné zabezpečiť, aby bol meraný povrch nerdzového plätu čistý a voľný od tukov, prachu alebo iného smetu.

Urobte viacmerové merania: Pre zabezpečenie presnosti môžete urobiť viac meraní na rôznych miestach plätu (ako napríklad v strede, na hranici, na koncoch plätu atď.) na potvrdenie súladu výsledkov merania.

Urobte viacmerové merania: Pre zabezpečenie presnosti môžete urobiť viac meraní na rôznych miestach plätu (ako napríklad v strede, na hranici, na koncoch plätu atď.) na potvrdenie súladu výsledkov merania.

Tolerancia ocelej plasty:

Tolerancia ocelej plasty sa týka povoleného chybového rozsahu medzi rozmierom plasty (vrátane hrúbky, šírky a dĺžky) a jej určeným rozmierom. Ovládanie tolerancie je veľmi dôležité pre spracovanie a konečné použitie ocelej plasty, osobitne v priemyselných oblastiach, ktoré vyžadujú vysokú mieru presnosti, ako sú stavebnictvo, letecký priemysel, medicína a výroba.

Plasty rôznych štandardov a rôznych hrúbok majú rôzne rozsahy tolerancie. Napríklad plasta 1,00 mm s toleranciou ±0,05 mm by mala mať hrúbku medzi 0,95 mm a 1,05 mm.

5. Test na koroziu

Testy na koroziu môžu slúžiť na posudzovanie odolnosti ocele pred oxidáciou a koroziou. Existuje niekoľko metód testovania na koroziu:

Test solným oparom: Užitková vzorka z nerdzového ocele je vystavená prostrediu solného oparu na testovanie jej odolnosti pred koroziou počas určitého obdobia. Nerdzová oceľ s dobrú odolnosťou pred koroziou (ako 316 nerdzová oceľ) by mala počas testu dlhšie nevykazovať žiadne zretné rezavienie.

Test solným oparom: Užitková vzorka z nerdzového ocele je vystavená prostrediu solného oparu na testovanie jej odolnosti pred koroziou počas určitého obdobia. Nerdzová oceľ s dobrú odolnosťou pred koroziou (ako 316 nerdzová oceľ) by mala počas testu dlhšie nevykazovať žiadne zretné rezavienie.

Oskorňovací test: Odolnosť nerdzových ocelí voči kyselinám sa testuje pomocou dusičnej kyseliny alebo iných koroziívnych látky. 316 nerdzová oceľ sa v tomto typu teste vykonáva veľmi dobre, kým 304 nerdzová oceľ je trochu menej odolná voči kyselinám.

Oskorňovací test: Odolnosť nerdzových ocelí voči kyselinám sa testuje pomocou dusičnej kyseliny alebo iných koroziívnych látky. 316 nerdzová oceľ sa v tomto typu teste vykonáva veľmi dobre, kým 304 nerdzová oceľ je trochu menej odolná voči kyselinám.

Tento test pomáha zistiť, či je nerdzová oceľ vhodná na dlhotrvajúcu úžitu v konkrétnom prostredí a tak sa vyhnete škodám na štruktúre spôsobeným koroziou.

6. Preštudujte si certifikácie a súlad so štandardmi

Oficiálni výrobci nerdzových ocelí bežne dodržiavajú medzinárodné štandardy a systémy riadenia kvality a získavajú príslušné certifikácie.

Rozumiem certifikácii:

Certifikát je zárukou kvality produktu. Bežné certifikácie nerdzových ocelí zahŕňajú:

ISO 9001: Osvědčenie systému kvality, čo znamená, že materiály vyrobené výrobcom splňujú medzinárodné štandardy manažmentu kvality.

ISO 9001: Osvědčenie systému kvality, čo znamená, že materiály vyrobené výrobcom splňujú medzinárodné štandardy manažmentu kvality.

Štandardy ASTM, EN: Tieto štandardy určujú chemickú sústavu, mechanické vlastnosti a požiadavky na kvalitu nerezového ocele.

Štandardy ASTM, EN: Tieto štandardy určujú chemickú sústavu, mechanické vlastnosti a požiadavky na kvalitu nerezového ocele.

CE osvedčenie: Predovšetkým na európskom trhu, znamená to, že nerezová oceľ splňuje európske normy bezpečnosti a životného prostredia.

CE osvedčenie: Predovšetkým na európskom trhu, znamená to, že nerezová oceľ splňuje európske normy bezpečnosti a životného prostredia.

Osvědčenie overenia:

Aby ste sa uistili, že produkty z nerezového ocele majú legálne a platné osvedčenia, môžete od dodávateľov požadovať certifikačné osvedčenia a správy o kvalite produktu. Zároveň môžete ich informácie o osvedčení overiť aj cez oficiálnu webovú stránku certifikačnej organizácie.

Dôležitosť dodržiavania:

Dodržiavanie pravidiel zabezpečuje, že výrobky z nerezového ocele splňujú priemyselné štandardy a nebude ich spôsobovať bezpečnostné riziká kvôli kvalitným problémom. Pod striktými kvalitnými požiadavkami majú dodržiavané produkty vyššiu spoľahlivosť a životnoschopnosť, a môžu ponúknuť lepšiu ochranu spotrebiteľom.

Preto, keď sa vyberáte nerezové plechy, má byť kvalita kľúčovým faktorom na zváženie, aby sa zabezpečil správny stupeň kvality, výkonu a ekonomickej účinnosti. Som profesionálny výrobca nerezových plechov, kontaktujte nás pre viac podrobností.

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )

info@steelgroups.com

info@steelgroups.com