- Oversikt

- Relaterte produkter

Beskrivelse:

Beskrivelse:

«NM» i NM600 refererer til skaderesistent plade, de første bokstavene i «Nai» og «Mo», og 600 er Brinellhardhetsverdien (HB-verdi). Graden er høyere enn NM500, NM450, NM400 og NM360.

NM600 gjennomføringstandard: gjennomfør bedriftsstandard Q/XGJ166-2009

Leveransestatus: kverning og temperering (kverning + temperering)

Spesifikasjoner:

Spesifikasjoner:

|

Produktnavn |

Motstandsdyktig Stålplade |

|

Stålgrad |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Tykkelse |

2mm-300mm |

|

Bredd |

500-2500mm |

|

Lengde |

1000mm-12000mm eller etter kundens spesialforespørsel |

|

Toleranse |

Tynnelse: +\/–0,02mm, Bredd: +\/–2mm |

|

Leveringstid |

7-15 virkedager etter mottak av 30% nedbetaling |

|

Sertifisering |

BV SGS CE TUV |

|

Pakking |

Bundling med stålremme, Containertransport |

NM600 Stål Standard Sammenligning:

|

Stålgrad |

SSAB |

ThyssenKrupp |

JFE |

DILLIDUR |

Ruukki |

|

Nm600 |

HARDOX600 |

XAR600 |

- |

600V |

Raex600 |

NM600 Skadevaskmotstandende Stålplater Kjemisk Elementoppbygging (%):

|

Komponent |

C |

Ja, det er det. |

Mn |

P |

S |

CR |

Ni |

Mo |

Ti |

B |

AL |

|

Minimumsverdi |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Maksimal verdi |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

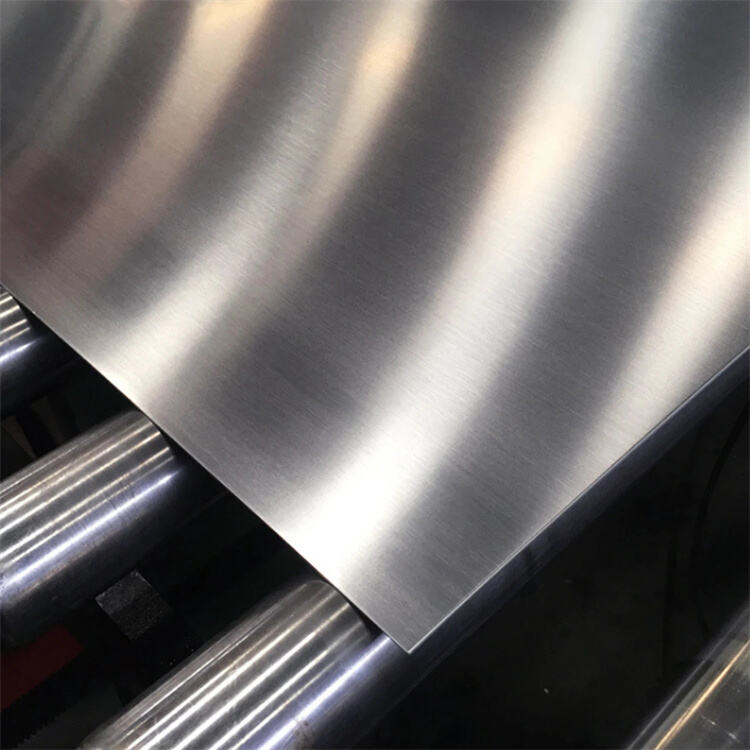

NM600 Slipningsmotstand Resistent Stålplater Maskinvaregenskaper:

|

Tykkelse |

Strekkstyrke |

Forlengeting eller Utstrekningsrate |

Hardhet |

|

t≤60 |

- |

- |

Overflatehardhet: 570~640HBW |

Fordeler med NM600:

Høy motstandsdyktighet mot slipning: Karboninnholdet i kjemisk sammensetningen av den legerede motstandsdyktige laget er 4-5%, og chromeinnholdet er så høyt som 25-30%. Volumfraksjonen av Cr7C3-karbid i dens metallurgiske struktur når over 50%, makrohardheten er HRC56-62, og hardheten til chrome karbid er HV1400-1800. Fordi karbidene er fordelt vertikalt i forhold til slipningsretningen, er motstandsdyktigheten mot slipning mer enn dobbelt så god, selv sammenlignet med gjuterilegeringer med samme sammensettning og hardhet.

Høy motstandsdyktighet mot slipning: Karboninnholdet i kjemisk sammensetningen av den legerede motstandsdyktige laget er 4-5%, og chromeinnholdet er så høyt som 25-30%. Volumfraksjonen av Cr7C3-karbid i dens metallurgiske struktur når over 50%, makrohardheten er HRC56-62, og hardheten til chrome karbid er HV1400-1800. Fordi karbidene er fordelt vertikalt i forhold til slipningsretningen, er motstandsdyktigheten mot slipning mer enn dobbelt så god, selv sammenlignet med gjuterilegeringer med samme sammensettning og hardhet.

God motstandsdyktighet mot impakt: Substratet i den slipresistente sammensatte stålplaten er et tøft materiale som lavkarbonstål eller lavlegert, hvilket viser fordelen med bimetal. Slipresistenslaget motsetter seg slitasjen fra det slitasjeførede mediumet, mens substratet bærer lasten av mediumet, så det har god motstandsdyktighet mot impakt. Det kan klare impakten og slitasjen fra høye hoppere i materialetransport-systemer.

God motstandsdyktighet mot impakt: Substratet i den slipresistente sammensatte stålplaten er et tøft materiale som lavkarbonstål eller lavlegert, hvilket viser fordelen med bimetal. Slipresistenslaget motsetter seg slitasjen fra det slitasjeførede mediumet, mens substratet bærer lasten av mediumet, så det har god motstandsdyktighet mot impakt. Det kan klare impakten og slitasjen fra høye hoppere i materialetransport-systemer.

God motstands evne mot varme: Det anbefales at den legemesske laget av kobberblendingen brukes under ≤600 arbeidsbetingelser. Hvis vanadium, molybdenum og andre blandingselementer legges til i det legemesske laget av kobberblendingen, kan det tåle høytemperaturutslitasjon på ≤800. Den anbefalte driftstemperaturen er som følger: Vanlig karbonstål grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 380; Lavkobberhittmodig stålplate (15CrMo, 12Cr1MOV osv.) grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 540; Hittmodig rostfritt stål grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 800.

God motstands evne mot varme: Det anbefales at den legemesske laget av kobberblendingen brukes under ≤600 arbeidsbetingelser. Hvis vanadium, molybdenum og andre blandingselementer legges til i det legemesske laget av kobberblendingen, kan det tåle høytemperaturutslitasjon på ≤800. Den anbefalte driftstemperaturen er som følger: Vanlig karbonstål grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 380; Lavkobberhittmodig stålplate (15CrMo, 12Cr1MOV osv.) grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 540; Hittmodig rostfritt stål grunnsubstans anbefales å brukes under arbeidsbetingelser som ikke overstiger 800.

Applikasjoner:

Applikasjoner:

NM600 brukes utvidet i metallurgi, kull, sement, elektrisitet, glass, gruvevirksomhet, byggematerialer, tegler og andre industrier.

Pakking av produkt:

Pakking av produkt:

Vi bruker de aller sikreste og effektiveste pakkeveiene for alle typer leveranser.

FAQ:

FAQ:

1.Q: Hvor lenge kan leveringen ta?

A: For varer på lager, vil vi sende frakt innen 5-7 dager etter mottatt depósito; for varer som krever ny produksjon av vanlige materialer, vanligvis sender vi frakt innen 10-15 dager; for varer som krever ny produksjon av spesielle og sjeldne materialer, trenger vi vanligvis 20-30 dager for å sende frakt.

2.Q: Kan jeg besøke fabrikk?

A: Jada, velkommen til å besøke fabrikken vår når som helst.

3.Q: Hvor er dere?

A: I Anyang i provinsen Henan.

4.Q: Hvilke sertifiseringer har produktene dine?

A: Vi har ISO 9001, BV, SGS, CE, TUV og andre sertifiseringer.

5.Q: Hva er betingelsene for betaling?

A: 30% T/T-depósito forvekst, 70% T/T-resten innen 5 dager etter mottatt B/L-kopi, 100%. Uopprettelig L/C ved første presentasjon, 100% Uopprettelig L/C etter mottatt B/L 30-120 dager, O/A.

Merkelapp:

NM600, Kina Motstandsdyktig Stålplade produsenter, leverandører, fabrikk, NM300 Slipningsmotstandsdyktig Stålplade, NM360 Slipningsmotstandsdyktig Stålplade, NM500 Slipningsmotstandsdyktig Stålplade, Høy Slipningsmotstand Og Høy Tørrhet, Høy Kvalitet, NM600 Motstandsmodne Stålplater ,NM300TP ,NM400 ,NM400E ,Nm450 ,NM450E ,Nm500 ,NM500E