- Oversikt

- Relaterte produkter

Beskrivelse:

Beskrivelse:

Mn13 er valget av motstandsdyktige materialer som kan motstå sterke impakter, høytryksmaterialeforskjøring osv. Det har arbeidsmotstandsdyktige egenskaper som andre motstandsdyktige materialer ikke kan matche. Under virkningen av stor impaktslast eller stor kontaktpresje blir overflaten av stålplaten arbeidsmotstandsdyktig, og overflatehardheten øker raskt fra HB200 til over HB500, noe som fører til et høygradig motstandsdyktig overflateskjikt, mens det indre austenittskjiktet av platen fortsatt opprettholder god impakttykke.

Det finnes to karakteristikk ved høymanganstål:

1.Jo større den eksterne impaktslasten, jo høyere motstandsdyktighet vil dens egen overflateskjikt ha;

2.Som det hardnete overflateskjiktet gradvis slipper bort, vil det dannes et nytt arbeidsmotstandsdyktig skjikt kontinuerlig.

De spesielle egenskapene ved høy mangangstål er egnet for å lage motstandsdyktige komponenter som kan klare langtidsmotning av materialer med høy impakt. Det har lenge blitt brukt i maskinutstyr som metallurgi, gruvevirksomhet, byggematerialer, jernbaner, elektrisitet og kull.

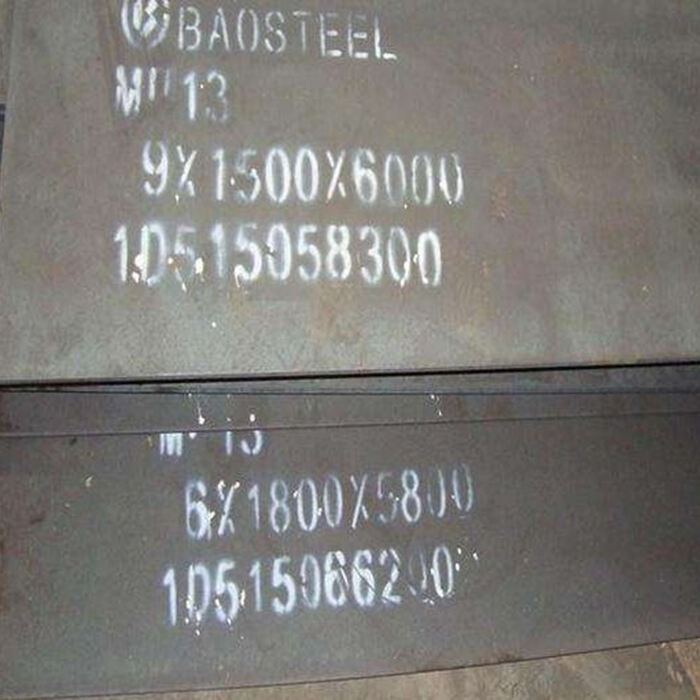

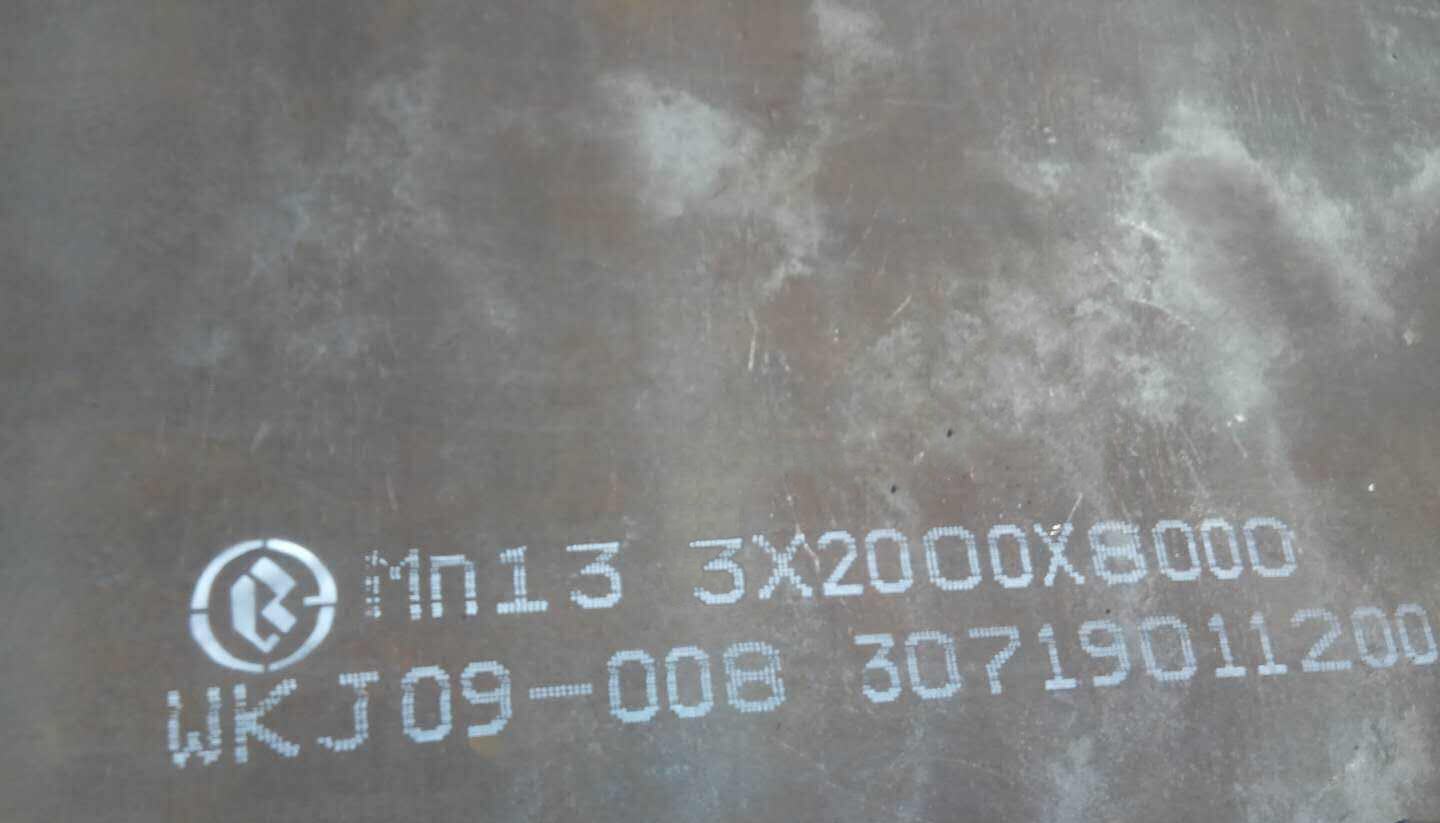

Spesifikasjoner:

Spesifikasjoner:

|

punkt |

Mn13 |

|

Bredd |

1000 opp til 3000mm |

|

Standard Kvalitet |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400,; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

TEKNOLOGISK PROSESS |

kontrollert rulling, varmvridd, normalisering, tempering, annealing, kvelling, N+T, Q+T |

|

Tykkelse |

2 opp til 300mm |

|

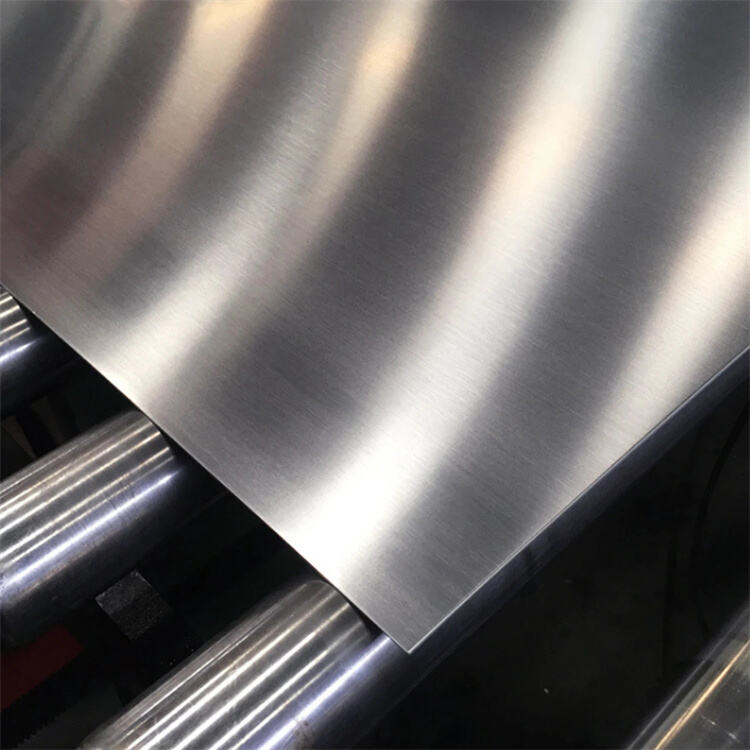

Overflate |

renset, sprøytning, avslutning og malering |

|

Lengde |

1000 opp til 12000mm |

Ekvivalente kvaliteter av Mn13 :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Kjemisk sammensetning av Mn13:

|

Kvalitet |

C |

Ja, det er det. |

Mn |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11.0~14.0 |

≤ 0,035, |

≤0.030 |

Mekanisk egenskap for Mn13:

|

Kvalitet |

Trekkstyrke (MPa) |

Forlenget (%)) |

Spenningsprestasjon (20℃) |

Første hardthetsverdi (HB) |

Hardthetsverdi etter hårdføring (HB) |

Kjølig bøyning (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90 (J) |

200-250 |

>300 |

kvalifisert |

Applikasjoner:

Applikasjoner:

Mn13 brukes ofte til å lage skovler tann for bagger, rullvegg og krusningvegg for kjeglekrusere, gaffelplater for knekkere, linerplater for kulemøller, jernbanebytter, platerhammere, hammerhoder, osv.

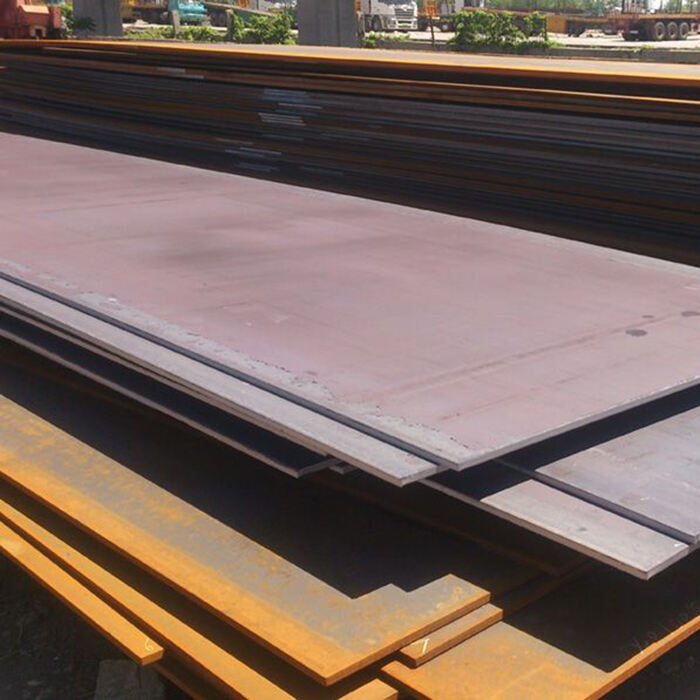

Pakking av produkt:

Pakking av produkt:

Vi bruker de aller sikreste og effektiveste pakkeveiene for alle typer leveranser.

FAQ:

FAQ:

1.Q: Hvor lenge kan leveringen ta?

A: For varer på lager, vil vi sende frakt innen 5-7 dager etter mottatt depósito; for varer som krever ny produksjon av vanlige materialer, vanligvis sender vi frakt innen 10-15 dager; for varer som krever ny produksjon av spesielle og sjeldne materialer, trenger vi vanligvis 20-30 dager for å sende frakt.

2.Q: Kan jeg besøke fabrikk?

A: Jada, velkommen til å besøke fabrikken vår når som helst.

3.Q: Hvor er dere?

A: I Anyang i provinsen Henan.

4.Q: Hvilke sertifiseringer har produktene dine?

A: Vi har ISO 9001, BV, SGS, CE, TUV og andre sertifiseringer.

5.Q: Hva er betingelsene for betaling?

A: 30% T/T-depósito forvekst, 70% T/T-resten innen 5 dager etter mottatt B/L-kopi, 100%. Uopprettelig L/C ved første presentasjon, 100% Uopprettelig L/C etter mottatt B/L 30-120 dager, O/A.

Merkelapp:

Mn13, Kina Høy Mn Skadebestandig Stål produsenter, leverandører, fabrikk, Skade-Korrosjon-Resistent Stål, Høy Kvalitet Hardet og Temperert Skadebestandig Stål, Høy Duktilitet Bryst Sprakk Arrester Skadebestandig Stål, Super Skadebestandig Stål, Høy Temperatur og Skadebestandig Stål, Høy Mn Skadebestandig Stål, Lav Gittforhold Skadebestandig Stål