- ġenerali

- Prodotti Relatati

Deskrizzjoni:

Deskrizzjoni:

Il-Mn13 hija l-iskelta għall-materiali antidura li jistgħu jagħmlu resistenti lil impatt tagħtagħtan, iddur tad-materiali b’pressjoni għoli, u ċief. Għandha karatteristiki ta' indurament fil-lavoru li ma jistgħux jmissu materiali oħra antidura. Fil-ħin mill-impatt tat-tliet kbar jew mill-pressjoni kontatt kbar, is-superfiji tal-plata jinduri fl-lavoru, u s-superfizzija durità tigri f'mod rapid minn HB200 lejnHB500 u fuq, ikollok produzzjon ta' strati superficiali altament antidura, mentliema l-austenit interna tal-plata jrimanu b’impattdarajiet bħala.

Għand il-ġelwie tal-manganese dawn dawn karatteristiki tiegħu:

1. Ikbar l-impatt estern, ikbar l-antidurazzjoni tal-strata superficiali proprija;

2. Meta strata superjali indurata tibda tiddur, strata ġdida ta' indurament fl-lavoru tiġifier tax-xah.

L-proprijetaj speciali tal-acier għoli-manganese jkunu adekwati għall-bidu ta' komponenti li jagħmlu lura kontra l-iskiera li tista' tkun flimkien għal periodi ikbar ta' iskiera ta' materjali ta' impatt għoli. Minn żmien il-ġdid, kien użat bil-kif widna f'maċħina skont il-metallurgija, is-sinjaliem, it-tielet strutturali, ir-railji, l-elektrika, u l-għol.

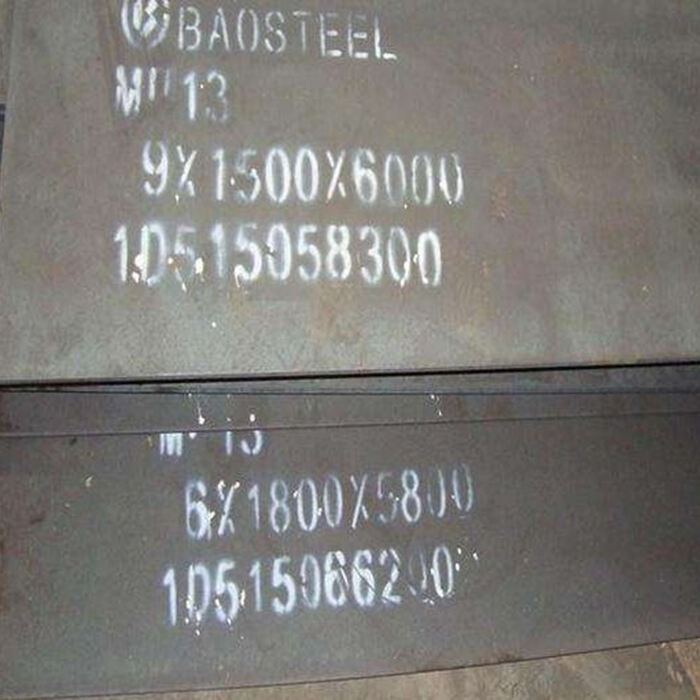

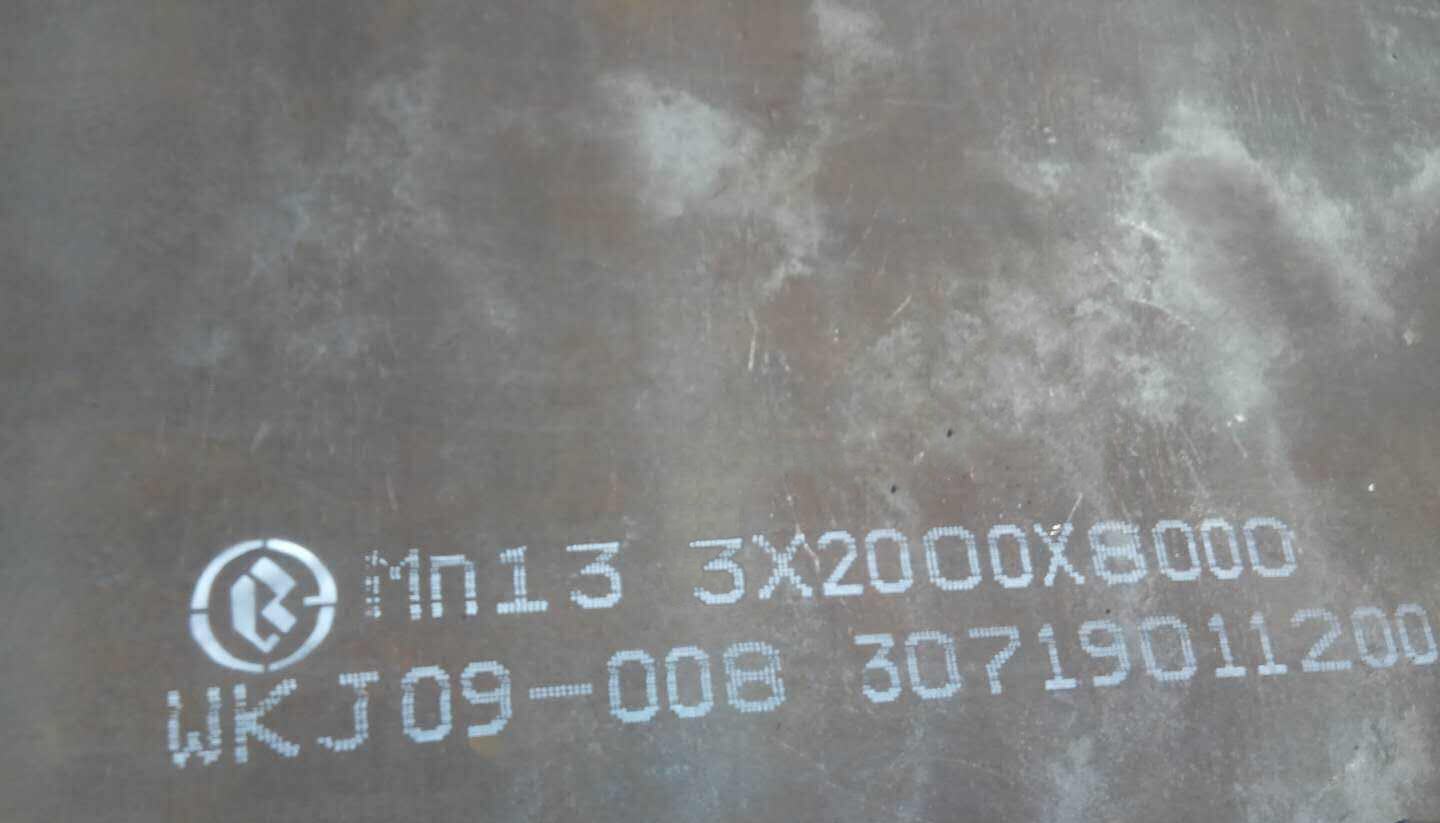

L-ispeċifikazzjonijiet:

L-ispeċifikazzjonijiet:

|

ġejt |

Mn13 |

|

Il-wisa' |

1000 għal 3000mm |

|

Grada Standaardu |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400,; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

PROċESS TECNOLOĠIKA |

rollar kontrollati, rolljar roħo, normalizzazzjoni, temperaturizzazzjoni, annealing, quenching, N+T, Q+T |

|

Thickness |

2 għal 300mm |

|

Surfacc |

nuqqas, blast, itħass, u l-inkoloraġġ |

|

It-tul |

1000 xgħiex 12000mm |

Gradi Ekwivalenti ta' Mn13 :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Kompożizzjoni Kemika tal-Mn13:

|

Darġa |

C |

Iev |

Mn |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11.0~14.0 |

≤0.035 |

≤0.030 |

Proprjetà Mekanika ta' Mn13:

|

Darġa |

Forza ta' trazzjoni (Mpa) |

Elongazzjoni (%) |

Perfurmanza tal-Impatt (20℃) |

Valur Inizjali ta' Drittizza (HB) |

Valur ta' Drittizza Baż il-Ħadd (HB) |

Fleksjar Fredd (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90(J) |

200-250 |

>300 |

Akkwatata |

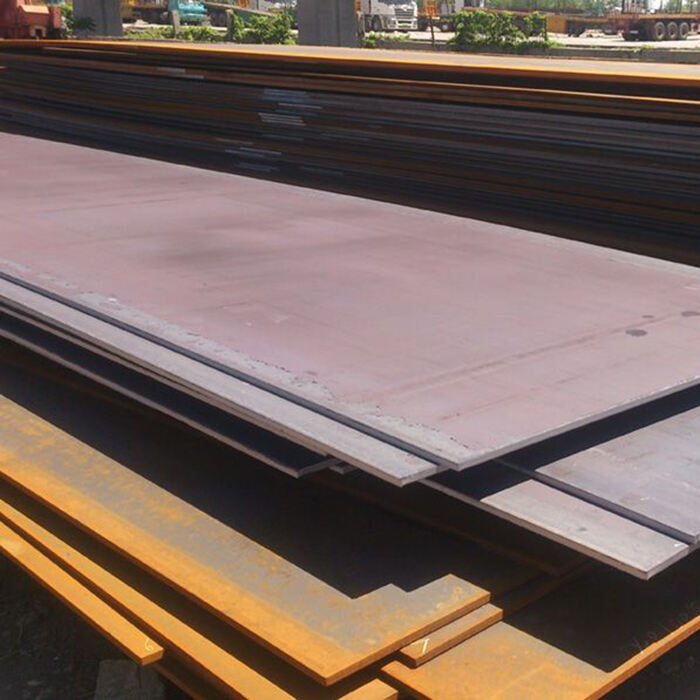

Applikazzjonijiet:

Applikazzjonijiet:

Mn13 tista' jkollu bżonn biex jagħmlu dantijiet tal-excavators, il-parete rottante u s-sħieda rottante tal-makkinijiet koniċi, forċoni tal-makkinijiet ħafifni, parati tal-balls mills, xabijiet relgjosi, martelli ta' lastri, u testi tal-martell, ecc.

Imballazzjoni tal-Prodott:

Imballazzjoni tal-Prodott:

Nhu tiegħiex l-aħħar modi ta’ pakkaġġ li huma is-Saf li jkunu u effettivament li jkunu għal kull tipi ta’ livell.

FAQ:

FAQ:

1.Q: Fih xi period ta' waqt ikun jogħġbix?

A: Għal prodotti magazzinieri, se jmiss il-shipments f’5-7 iorni wara li tibgħad id-deponuta; għal prodotti li jagħmlu ħtieġa ta’ produzzjoni ġdida għall-materjali komuni, ikollok jmiss il-shipments f’10-15 iorni; għal prodotti li jagħmlu ħtieġa ta’ produzzjoni ġdida għall-materjali speċjali u nissab, ikollok jkollhom bżonn 20-30 iorni biex jmiss il-shipment.

2.Q: Jistgħux nkunqis fuq ir-reġbi tiegħek?

A: Sigur, mħabbir li tkunqis ir-reġbi tagħna fl-oqsma.

3.Q: Fejn int?

A: Anyang fis-Sigriet Henan.

4.Q: X’certifikati għandek l-prodotti tiegħek?

A: Għandna ISO 9001, BV, SGS, CE, TUV u certifikati oħra.

5.Q: X’termini tal-pagament għandek?

A: 30% deponuta T/T fil-avanzata, 70% bilanċ T/T f’5 iorni wara B/L kopja, 100%. L/C neċessarju fil-vista, 100% L/C neċessarju wara li tirċievi B/L 30-120 iorni, O/A.

Tag:

Mn13, Prodottori Cini ta' ĦaġĠ Mn Alt Wear-Resistant Steel, Fornituri, Factory, Steel immaħluqa kontra il-wear u l-korrużjoni,Steel magħrufa u mitbida bil-gradi ewwel kontra l-wear,Steel għad-doktili tal-bidu tal-fissura kontra l-wear,Super Kontra l-Wear Steel,Steel Kontra it-Temperatura Nili u l-Wear,ĦaġĠ Mn Alt Wear-Resistant Steel,Steel Kontra l-Wear bi-Razzjonijiet Piżzi Talbaħ