- Apžvalga

- Susijusios produktai

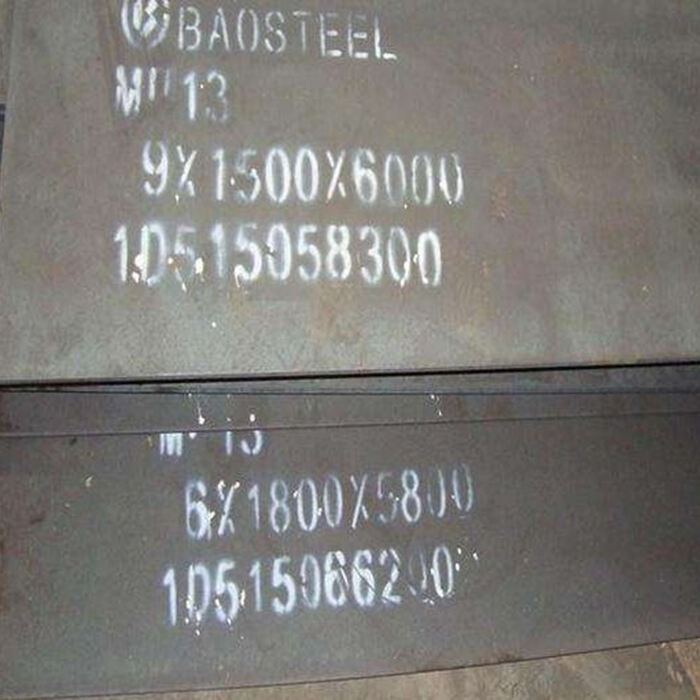

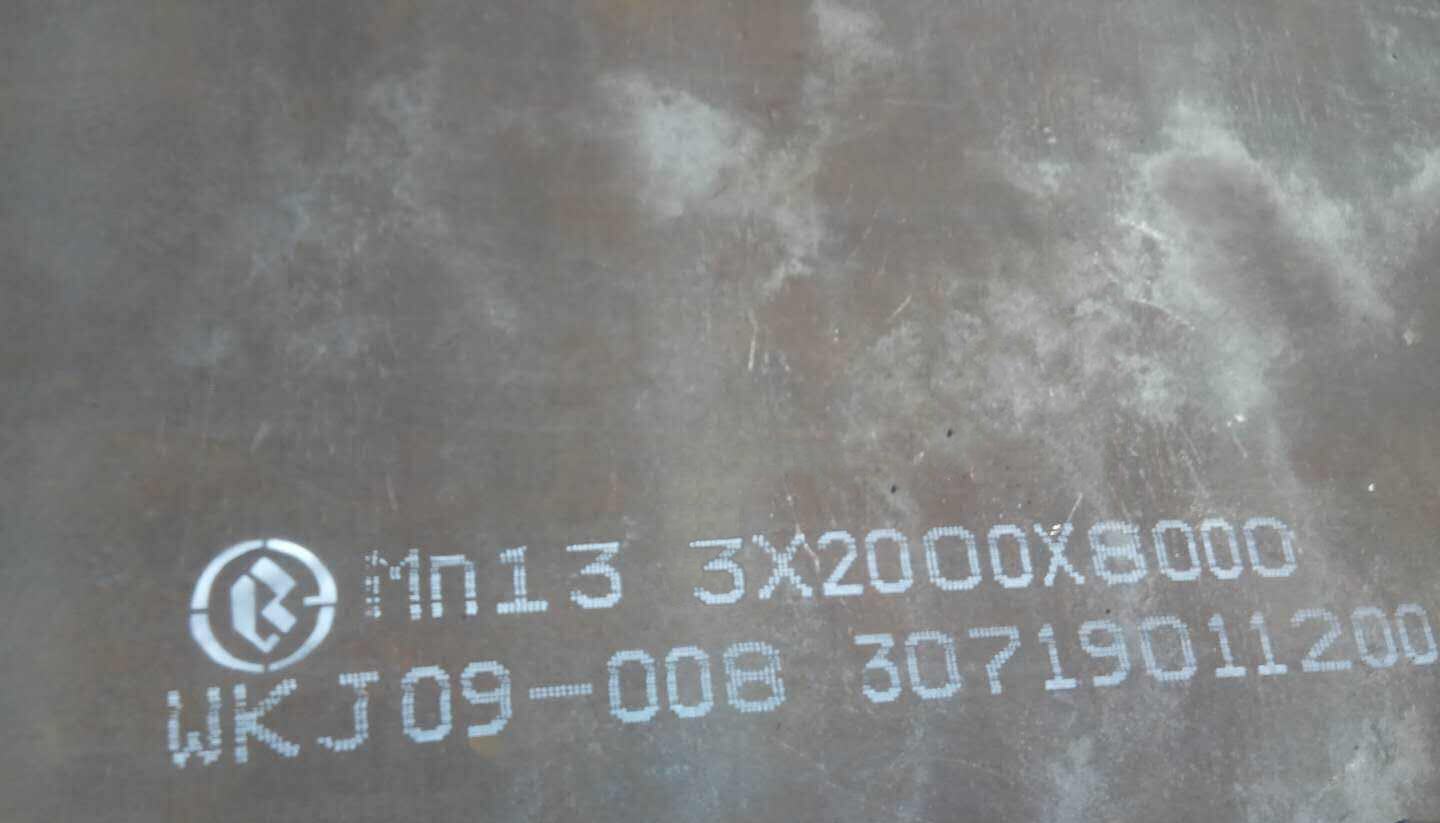

Aprašymas:

Aprašymas:

Mn13 yra trikdžių medžiagų pasirinkimas, kuris gali išlaikyti stiprius smūgius, aukštą slėgį ir pan. Jis turi dirbtinio tvirtinimo savybes, kurių kitos trikdžių medžiagos neturėtų. Didelio smūgio apkrovos arba didelio kontaktinio slėgio veiksmu plieno plokštės paviršius yra dirbtinai tvirtinamas, o paviršiaus tvirtumas greitai auga nuo HB200 iki daugiau nei HB500, taip sukurdami labai trikdžių poveikio paviršių sluoksnį, kol plieno plokštės vidinė austenitas vis dar laiko gera smūgių lankstumo savybę.

Aukštos manganinio plieno yra du charakteristika:

1. Kartu su didesniu išoriniu smūgiu apkrova, jo savo paviršiaus sluoksnio trikdžių savybės yra didesnės;

2. Kai paviršinis dirbtinai tvirtintas sluoksnis pakrenta, kartu bus nekilvuojamai formuojamas naujas dirbtinio tvirtinimo sluoksnis.

Aukštos mangano plieno ypač savybės tinka kenkamojo įrangos gaminiams, kurie išlaiko ilgalaikį aukštų triukšmo medžiagų veikimą. Jau ilgą laiką jis plačiai naudojamas mechaninėje įrangoje, tokiose srityse kaip metalurgija, gamtinės medžiagos, statyba, geležinkeliai, elektros ir anglių.

SPAKRINĖS:

SPAKRINĖS:

|

Prekė |

Mn13 |

|

Plotis |

1000 iki 3000mm |

|

Standartinis lygis |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

Technologinis procesas |

valdymas su lankstumu, karštas gilimo, normalizavimas, atsildymas, šaldymas, N+T, Q+T |

|

Storis |

2 iki 300mm |

|

Paviršius |

valymas, šliuzavimas, galutinis apdorojimas ir mažymas |

|

Ilgis |

1000 iki 12000mm |

Ekvivalentiniai Mn13 klasės :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Mn13 cheminis sudėtis:

|

Klasė |

C |

Taip. |

M |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11.0~14.0 |

≤ 0,035. |

≤0.030 |

Mn13 mechaninė savybė:

|

Klasė |

Tempimo stipris (Mpa) |

Ilgėjimas (%) |

Sutrikimo charakteristika (20℃) |

Pradinis tvirtumo rodiklis (HB) |

Tvirtumo rodiklis po šlamtingo (HB) |

Šaltasis lankymas (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90 (J) |

200-250 |

>300 |

Kvalifikuotas |

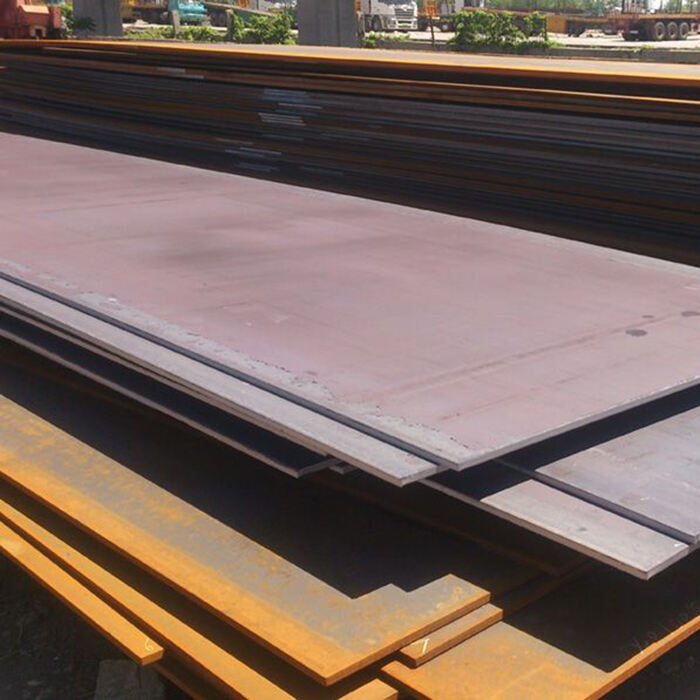

Programos:

Programos:

Mn13 dažniausiai naudojamas gaminti iškrovimo krūvų dantynes, konuso smulkintuvo suolą ir smulkintuvo plokštę, čenachinių smulkintuvų skardus, buriaklių apsauginių plokščių, geležinkelio perjungtukų, plonų cinklių, kovinių galvų ir kt.

Produkto pakavimas:

Produkto pakavimas:

Mes naudojame saugiausius ir efektyviausius pakavimo būdus visoms tiekimo tipams.

DUK:

DUK:

1.K: Kiek laiko reikia norint išsiųsti?

A: Inventoriaus produktams, siūlomasi pristatymas per 5-7 dienas po užstato mokėjimo; produktams, kurie reikalauja naujos gamybos iš paprastų medžiagų, paprastai pristatoma per 10-15 dienų; produktams, kurie reikalauja naujos gamybos iš specialių ir retųjų medžiagų, paprastai reikia 20-30 dienų norint pristatyti.

2.K: Ar aš galiu aplankyti jūsų fabriką?

A: Tikrai, visada malonūs matyti jūsų aplankant mūsų gamyklos bet kada.

3.K: Kur esate?

A: Anyang mieste Henano provincijoje.

4.K: Kokių sertifikatų turi jūsų produktai?

A: Mes turime ISO 9001, BV, SGS, CE, TUV ir kitus sertifikatus.

5.K: Kokie yra jūsų mokėjimo sąlygos?

A: 30% T/T pirmokis iš anksto, 70% T/T likutis per 5 dienas po B/L kopijos, 100%. Nepakeičiamas L/C nuožiūrėjimo metu, 100% nepakeičiamas L/C gavus B/L 30-120 dienas, O/A.

Žymė:

Mn13, Kinijos aukštos Mn trikdinčiosios plieno gamintojai, tiekėjai, gamykla, trikdinčiojo ir korozijos atsparaus plieno, aukštos klasės maitintas ir atšilimas trikdinčiojo plieno, aukštos lankstumo trūkstamosios sprendimo trikdinčiojo plieno, super trikdinčiojo plieno, aukštos temperatūros ir trikdinčiojo plieno, aukšto Mn trikdinčiojo plieno, žemos gręžties santykio trikdinčiojo plieno