사람들은 종종 어떻게 선택해야 하는지 묻습니다 I형 강재와 H-빔 , 모양이 유사한 경우.

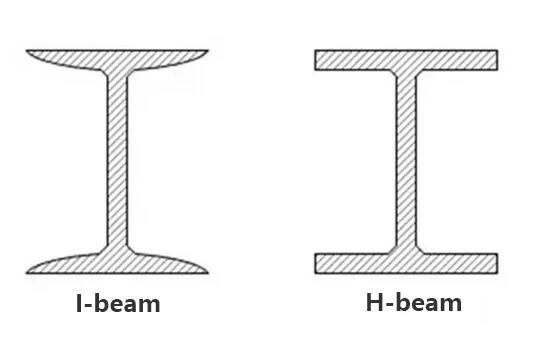

많은 사람들이 I형 강재는 중국에서 사용하는 이름이고 H형 강재는 해외에서 사용하는 이름이라고 생각합니다. 하지만 이 인식은 잘못된 것입니다. H형 강재와 I형 강재는 모양에서 다르며, 아래 그림에 표시되어 있습니다:

I형 강재란 무엇인가요?

I 빔 강철 보라고도 하며, 단면의 형태는 문자 "I"의 형태입니다. 날개는 H형 강재와 유사하지만, I형 강재의 벽은 일반적으로 H형 강재보다 얇고, 날개는 비교적 좁습니다.

H형강은 주로 일반 H형강, 경량 H형강 및 넓은 날개 H형강으로 나뉩니다. 날개와 웨브 높이의 비율에 따라 넓은, 중간 및 좁은 날개 H형강으로 나뉩니다. 처음 두 가지의 사양은 10-60이며, 이는 해당 높이가 10-60cm임을 의미합니다.

같은 높이에서 경량 H형강은 좁은 날개, 얇은 웨브 및 가벼운 무게를 가지고 있습니다. 넓은 날개 H형강은 또한 H형강이라고 불립니다. 그 단면은 두 개의 평행한 다리와 다리 내측에 기울기가 없는 특징이 있습니다. 이것은 경제적인 단면 강재로, 네 굴절 만능 압연기에서 압연되므로 "만능 H형강"이라고도 합니다. 일반 H형강과 경량 H형강은 국가 표준을 형성했습니다.

이름에서 알 수 있듯이, I형 강재는 "I"자형 단면의 강재입니다. 상하 유탕의 내부 표면은 일반적으로 1:6의 경사를 가지고 있어 유탕이 바깥쪽으로 얇아지고 안쪽으로 두꺼워집니다. 그 결과, I형 강재의 두 주요 평면에서 단면 특성이 매우 달라 응용 시 강재의 강도 특성을 충분히 발휘하기 어렵습니다. 비록 I형 강재 시장에 두꺼운 I형 강재가 등장했지만, I형 강재의 구조는 그 자체로 비틀림 성능의 한계를 가지고 있습니다.

H형 강재란?

H형 강재는 "H"자형 단면을 가진 강재로, 주로 두 개의 평행한 유탕과 하나의 수직 웹으로 구성됩니다.

H형 강재는 경제적이고 효율적인 프로필로, 단면적 분배가 더욱 최적화되고 강도 대 중량 비율이 더욱 합리적입니다. 그 이름은 단면이 영어 문자 "H"와 같기 때문에 붙여졌습니다. H형 강재의 모든 부분이 직각으로 배열되어 있어 모든 방향에서 강한 휨 저항, 간단한 구조, 비용 절감 및 가벼운 구조 중량을 제공하며, 널리 사용되고 있습니다.

H형 강재는 오늘날의 철골 구조 건물에서 널리 사용되는 프로필입니다. 이는 I형 강재와 비교했을 때 많은 차이점이 있습니다. 첫째, 날개(flange) 부분이며, 둘째로, 날개의 내부 표면에는 기울기가 없고 상하 표면이 평행합니다. H형 강재의 단면 특성은 전통적인 I형 강재, 채널 강재 및 각강보다 현저히 우수합니다.

H형 강재의 두 외부 가장자리 내측은 기울기가 없고 곧게 뻗어 있습니다. 이는 H형 강재의 용접과 연결이 I형 강재보다 간단하며, 단위 무게당 기계적 성질이 더 나아 많은 자재와 시공 시간을 절약할 수 있습니다. I형 강재의 단면은 압력과 인장에 대응하는 능력이 우수하지만, 날개가 너무 좁아 비틀림에 저항하는 단면 크기를 갖추지 못합니다. H형 강재는 그 반대이며, 각각 장단점이 존재합니다.

외형으로 I형 보와 H형 보를 구분하는 방법?

I형 보(I-beams)와 H형 보는 외형에서 크게 다릅니다. 주로 단면 형태에서 차이가 나타납니다. 다음은 두 종류의 강재 간 주요 외형 차이입니다:

- 아이빔 (I자형 강재): 아이빔의 단면은 "I" 자 모양이다. 구체적으로, 아이빔의 단면은 수직 웨브(중간 부분)와 두 개의 수평 플랜지(윗부분과 아랫부분)로 구성되어 있다. 플랜지는 일반적으로 좁고 웨브는 얇기 때문에 전체 단면 모양은 간소화된 "I"처럼 보인다.

-

에이치빔: 에이치빔의 단면은 "H"자 형태이며, 웨브와 플랜지로 구성되어 있다. 그러나 아이빔과 달리, 에이치빔의 플랜지는 아이빔보다 더 넓고 두껍고 웨브는 비교적 얇다.

에이치빔 대 아이빔

무엇인가 에이치빔과 아이빔의 차이점 ?

1. 일반적 이-beam 또는 경량 이-beam은 비교적 높고 좁은 단면 크기를 가지므로, 단면의 두 주축에 대한 관성모멘트가 상당히 다릅니다. 따라서 일반적으로 웨브 평면 내에서만 굽힘을 겪는 부재나 격자 구조의 부재로 사용될 수 있으며, 축방향 압축 부재나 웨브 평면과 수직으로 굽힘을 받는 부재로는 적합하지 않아 그 적용 범위가 크게 제한됩니다.

2. H형 강재는 높은 효율성과 경제성을 가진 단면 형상입니다 (다른 종류로는 냉간 압연 박벽 강재, 파형 강판 등이 있습니다). 합리적인 단면 형태 덕분에 강재의 효율성을 더욱 높이고 전단 능력을 향상시킬 수 있습니다. 일반 I형 강재와 달리 H형 강재의 날개는 넓혀져 있으며 내외 표면은 보통 평행하여 고강도 볼트로 다른 부품들과 쉽게 연결할 수 있습니다. 그 크기는 합리적인 시리즈를 구성하며 모델이 완전하여 설계 및 선택이 용이합니다 (크레인용 I형 강재 제외).

3. H형 강재의 날개는 두께가 동일합니다. 이를 구성하는 단면은 롤링된 부분과 세 개의 판을 용접한 조합 단면으로 이루어질 수 있습니다. I형 강재는 롤링된 단면입니다. 생산 기술이 부족하여 날개의 내부 가장자리에 1:10의 경사가 있습니다. H형 강재의 압연은 일반적인 I형 강재와 다릅니다. 일반적으로는 수평 압연기 한 셋만 사용하지만, H형 강재는 날개가 넓고 경사가 없거나 매우 작기 때문에 추가로 수직 압연기를 한 셋 더 설치하여 동시에 압연해야 합니다. 따라서 그 압연 공정과 장비는 일반 압연기보다 복잡합니다. 중국에서 생산할 수 있는 압연된 H형 강재의 최대 높이는 800mm입니다. 이를 초과하면 용접된 조합 단면이 됩니다.

4. I형 강재의 측면 길이는 작고 높이는 크기 때문에 한 방향의 힘만 견딜 수 있습니다.

5. H형 강재의 홈은 깊고 두껍기 때문에 두 방향의 힘을 견딜 수 있습니다.

6. 철골 구조물의 발전에 따라 I자형 강재만으로는 충분하지 않습니다. 즉, 두꺼운 I자형 강재는 하중을 지지하는 기둥으로 사용될 때 불안정해질 수 있습니다.

7. I자형 강재는 보로만 사용할 수 있고, H자형 강재는 구조물의 하중 지지 기둥으로 사용할 수 있습니다.

8. H자형 강재는 I자형 강재보다 단면 기계적 성질이 더 우수한 경제적인 단면 강재입니다. 그 이름은 단면의 모양이 영어 문자 'H'와 같기 때문에 붙여졌습니다. 열간 압연 H자형 강재의 날개는 I자형 강재보다 넓으며, 측면 강성이 크고 굽힘 저항이 강합니다. 동일한 사양에서 H자형 강재의 무게는 I자형 강재보다 가볍습니다.

9. I자형 강재의 날개는 변형 단면으로, 중심부 근처에서는 두껍고 바깥쪽으로 갈수록 얇아집니다. 반면 H자형 강재의 날개는 일정 단면입니다.

10. HW, HM, 및 HN은 H자형 강재의 일반적인 이름들입니다. H자형 강재는 용접된 것이며, HW, HM, HN은 열간 압연된 것입니다.

11.HW는 기본적으로 높이와 날개 너비가 같은 H형강으로, 주로 철근 콘크리트 프레임 구조의 강심 기둥에 사용되며, 이를 강성 강기둥이라고도 합니다. 주로 강구조물의 기둥에 사용됩니다.

12.HM은 H형강의 높이와 날개 너비 비율이 약 1.33~1.75인 것으로, 주로 강구조물에서 사용됩니다: 강 프레임 기둥으로 사용되고, 동적 하중을 받는 프레임 구조의 프레임 보로도 사용됩니다. 예: 장비 플랫폼.

13.HN은 H형강의 높이와 날개 너비의 비율이 2 이상인 것으로, 주로 보에 사용됩니다. I형강의 사용은 HN형강과 같습니다.

우리는 전문적인 강재 제조업체입니다. 필요가 있다면 언제든지 저희에게 연락할 수 있습니다!

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )  info@steelgroups.com

info@steelgroups.com