- Áttekintés

- Kapcsolódó termékek

Leírás:

Leírás:

A PPGI tetőlap, más néven Előre Festett Galvanizált Vas Tetőlap, egy olyan tetőanyag, amelyet galvanizált vas alapanyag felületére védelmi réteget alkalmazva készítenek. Ez a típusú tetőlap széles körben használnak lakos-, kereskedelmi és ipari épületek tetőrendszereiben, miatt hosszú tartóssága, változatos megjelenése és rostellenes tulajdonsága.

Műszaki adatok:

Műszaki adatok:

|

Termék |

PPGI tetőlap |

|

Szélesség |

vásárló igényei szerint |

|

Szín |

RAL szín vagy Ügyfél igényei szerint |

|

Vastagság |

Hűtött formálás: 0,1~4,0mm; Hősoros: 4mm~100mm |

|

Hosszúság |

100mm-tól 12000mm-ig vagy a vásárló kérése szerint |

|

Hosszúság |

100mm-tól 12000mm-ig vagy a vásárló kérése szerint |

|

Szabványok |

AISI ASTM JIS SUS DIN GB |

|

Tanúsítványok |

SGS, TV, BUV |

|

Csomagolás |

Ipari szabványos csomagolás |

A PPGI tetőlap jellemzői:

A PPGI tetőlap jellemzői:

Magas Tartósság: A galvanizált vas alapanyag és a festék kombinációja kiváló ellenállást biztosít a környezeti eroziók ellen, például a zöldség, a napfény és a pára ellen.

Magas Tartósság: A galvanizált vas alapanyag és a festék kombinációja kiváló ellenállást biztosít a környezeti eroziók ellen, például a zöldség, a napfény és a pára ellen.

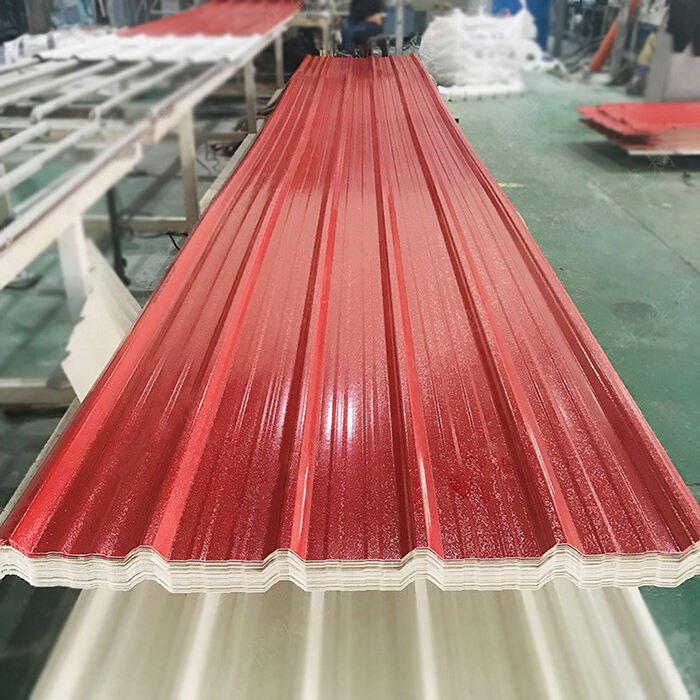

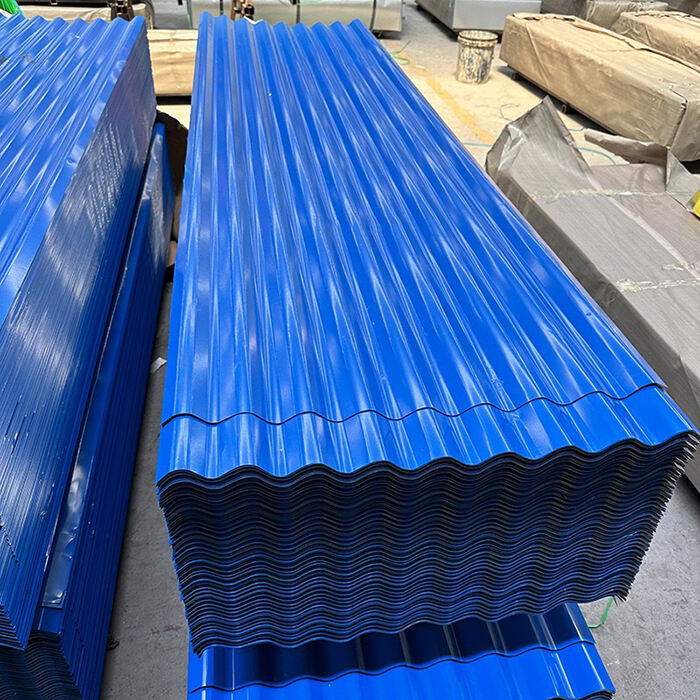

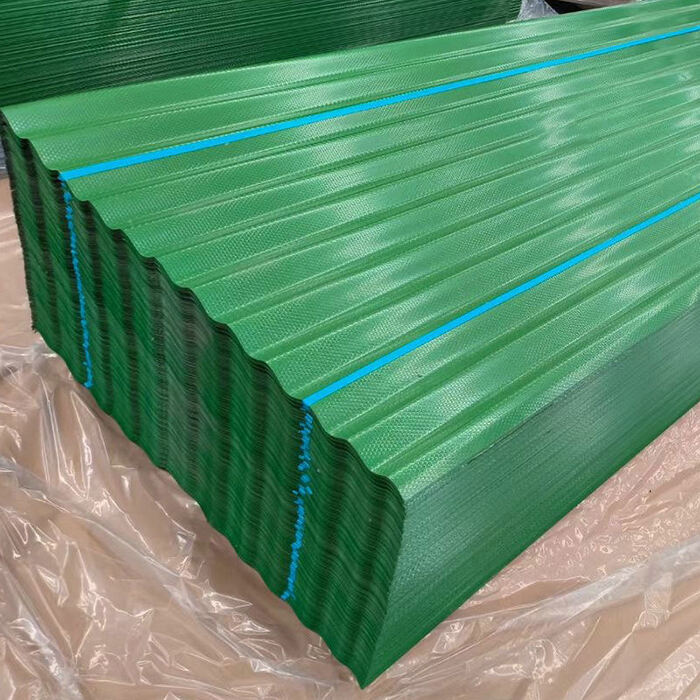

Gyakorlatilag végtelen estétikai lehetőségek: Sokféle színek, anyagszerkezetek és felületi kezelési lehetőségek állnak rendelkezésre az épület megjelenésének növeléséhez.

Gyakorlatilag végtelen estétikai lehetőségek: Sokféle színek, anyagszerkezetek és felületi kezelési lehetőségek állnak rendelkezésre az épület megjelenésének növeléséhez.

Könnyes tervezet: Annak ellenére, hogy nagy erőssal rendelkezik, a PPGI tetőlapok könnyek és egyszerűen szállíthatók és telepíthetők.

Könnyes tervezet: Annak ellenére, hogy nagy erőssal rendelkezik, a PPGI tetőlapok könnyek és egyszerűen szállíthatók és telepíthetők.

Korrózióállóság: A galvanizált réteg és a boríték dupla védelme hatékonyan meghosszabbíthatja az élettartamukat.

Korrózióállóság: A galvanizált réteg és a boríték dupla védelme hatékonyan meghosszabbíthatja az élettartamukat.

Jó hőszigetelési tulajdonságok: A speciális boríték hővisszaverő funkciót biztosít, amely segít az ágyú hűvös maradásában és az energia takarékos használatában.

Jó hőszigetelési tulajdonságok: A speciális boríték hővisszaverő funkciót biztosít, amely segít az ágyú hűvös maradásában és az energia takarékos használatában.

Szerkezet és összetétel:

Szerkezet és összetétel:

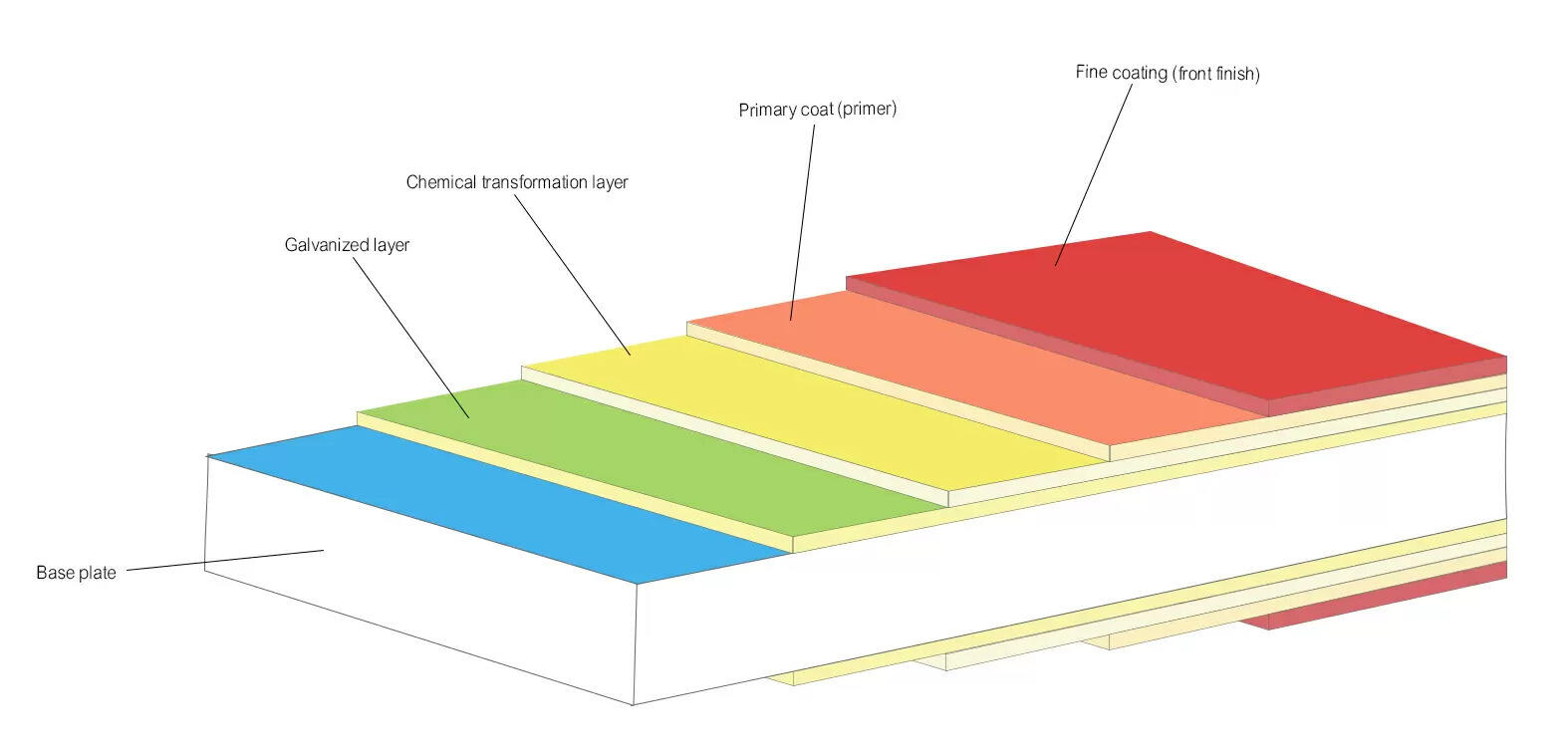

A PPGI tetőpanel több rétegből áll, mindegyik egy adott függvényt végzővel.

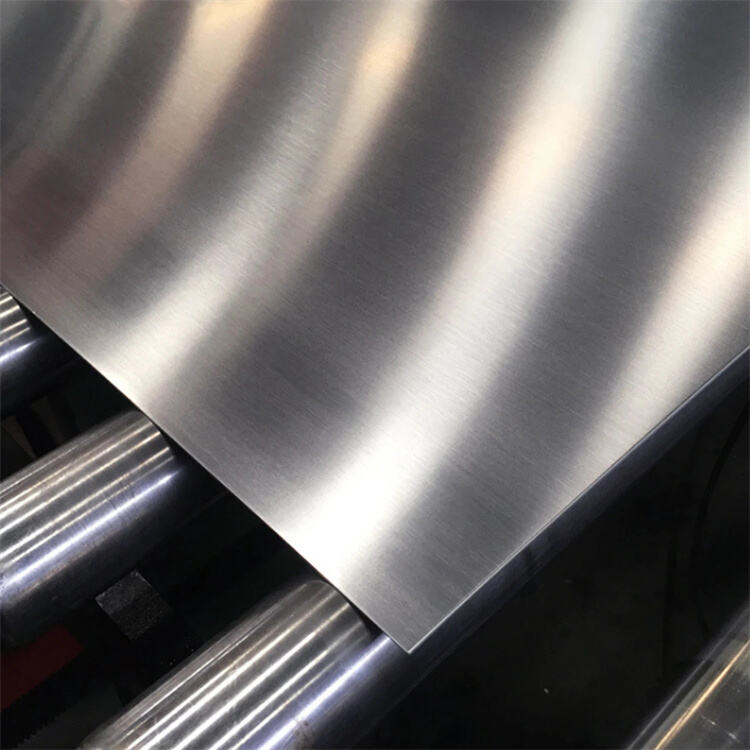

Alapanyag: Általánosan galvanizált vasból (GI) vagy alumínium-zincsövétymből (GL) készül, amely magas központi erősséget biztosít.

Alapanyag: Általánosan galvanizált vasból (GI) vagy alumínium-zincsövétymből (GL) készül, amely magas központi erősséget biztosít.

Előkészítési réteg: Növeli a boríték illeszkedését az alapanyaghoz és bizonyos korozió-ellenálló tulajdonságokkal rendelkezik.

Előkészítési réteg: Növeli a boríték illeszkedését az alapanyaghoz és bizonyos korozió-ellenálló tulajdonságokkal rendelkezik.

Alsófestés: Bariert teremt az alapanyag és a felső festék között, tovább növelve az illeszkedést és védelmet az alapanyag számára.

Alsófestés: Bariert teremt az alapanyag és a felső festék között, tovább növelve az illeszkedést és védelmet az alapanyag számára.

Felsőfesték: A külső réteg, amely sokféle színből és végzetből érhető, UV-védelemmel rendelkezik és növeli az estétikát.

Felsőfesték: A külső réteg, amely sokféle színből és végzetből érhető, UV-védelemmel rendelkezik és növeli az estétikát.

Hátulra festés: A tetőlap aloldalán található védelem, amely növeli a vízilagosságot és a súrlódási ellenállást.

Hátulra festés: A tetőlap aloldalán található védelem, amely növeli a vízilagosságot és a súrlódási ellenállást.

Alkalmazás:

Alkalmazás:

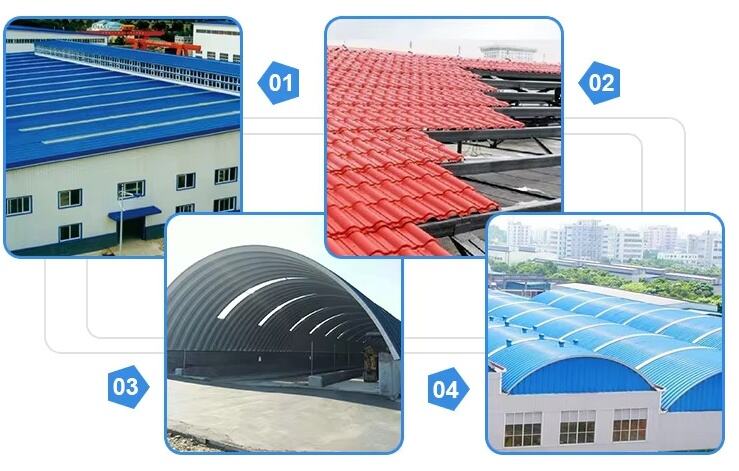

PPGI Tetőlap házakhoz, gyárakhoz, nagy épületekhez stb. használható.

Címke:

PPGI Tetőlap, Kína Színesen fedett lap Gyártók, Szállítók, Gyár, Fedett acél, Cinkelt Acélkötél, Cinkelt Acélcső, Cinkelt AcélLap, Színesen Fedett Kötél, Színesen Fedett Hullámás Lap