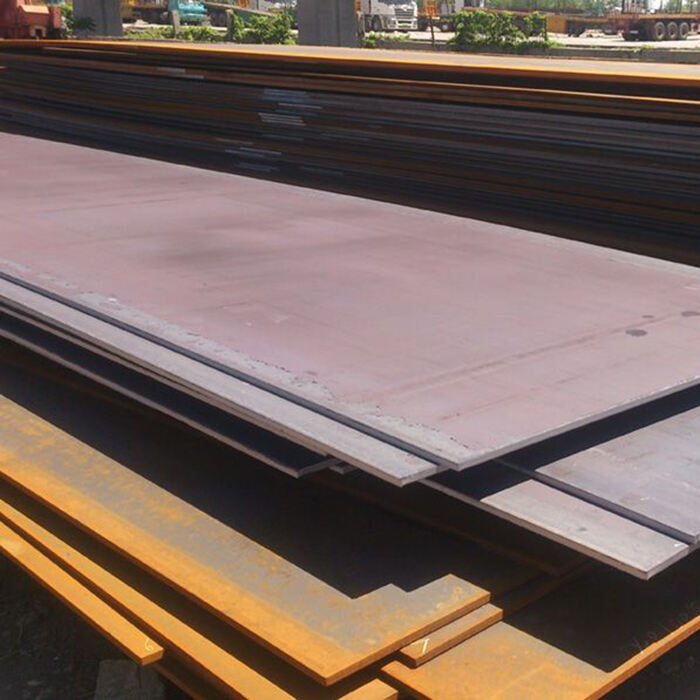

- vista xeral

- Produtos relacionados

Descrición:

Descrición:

Mn13 é a elección entre os materiais resistentes ao desgaste que poden resistir impactos fortes, desgaste de materiais baixo alta presión, etc. Ten características de endurecemento por traballo que outros materiais resistentes ao desgaste non poden igualar. Baixo acción dunha carga de impacto grande ou un escoamento de contacto elevado, a superficie da chapa de acero endurece polo traballo, e a dureza da superficie aumenta rapidamente desde HB200 ata máis de HB500, xerando así unha capa superficial altamente resistente ao desgaste, mentres que o austenito interno da chapa segue mantendo boas propiedades de resistencia ao impacto.

O acero de alto manganeso ten dúas caracterísicas:

1. Maior é a carga de impacto externa, maior será a resistencia ao desgaste da súa capa superficial;

2. À medida que a capa endurecida na superficie vai desgastándose, formarase continuamente unha nova capa de endurecemento por traballo.

As propiedades especiais do acero de alto manganeso son adecuadas para fabricar compoñentes resistentes ao desgaste que aguantan o desgaste a longo prazo de materiais de alto impacto. Fai moito tempo que se usa amplamente en equipos mecánicos como metalurgia, minería, materiais de construción, ferrocarriles, electricidade e carbón.

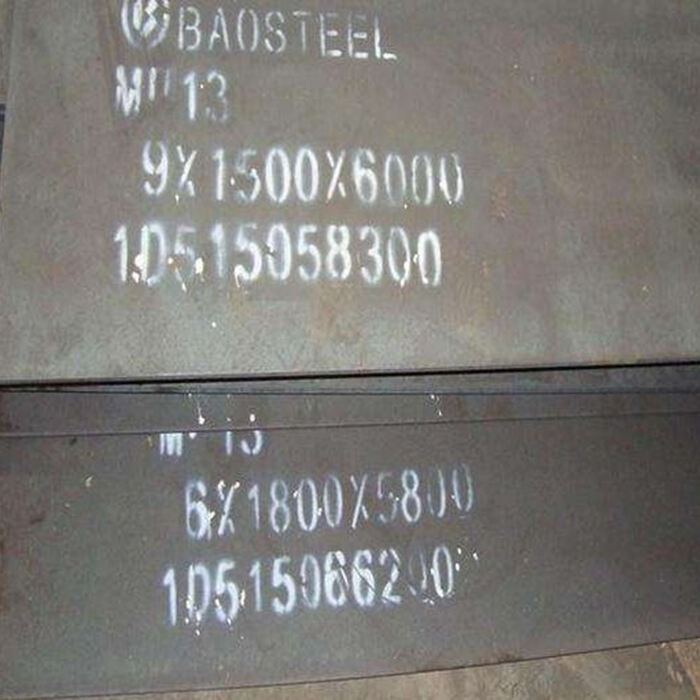

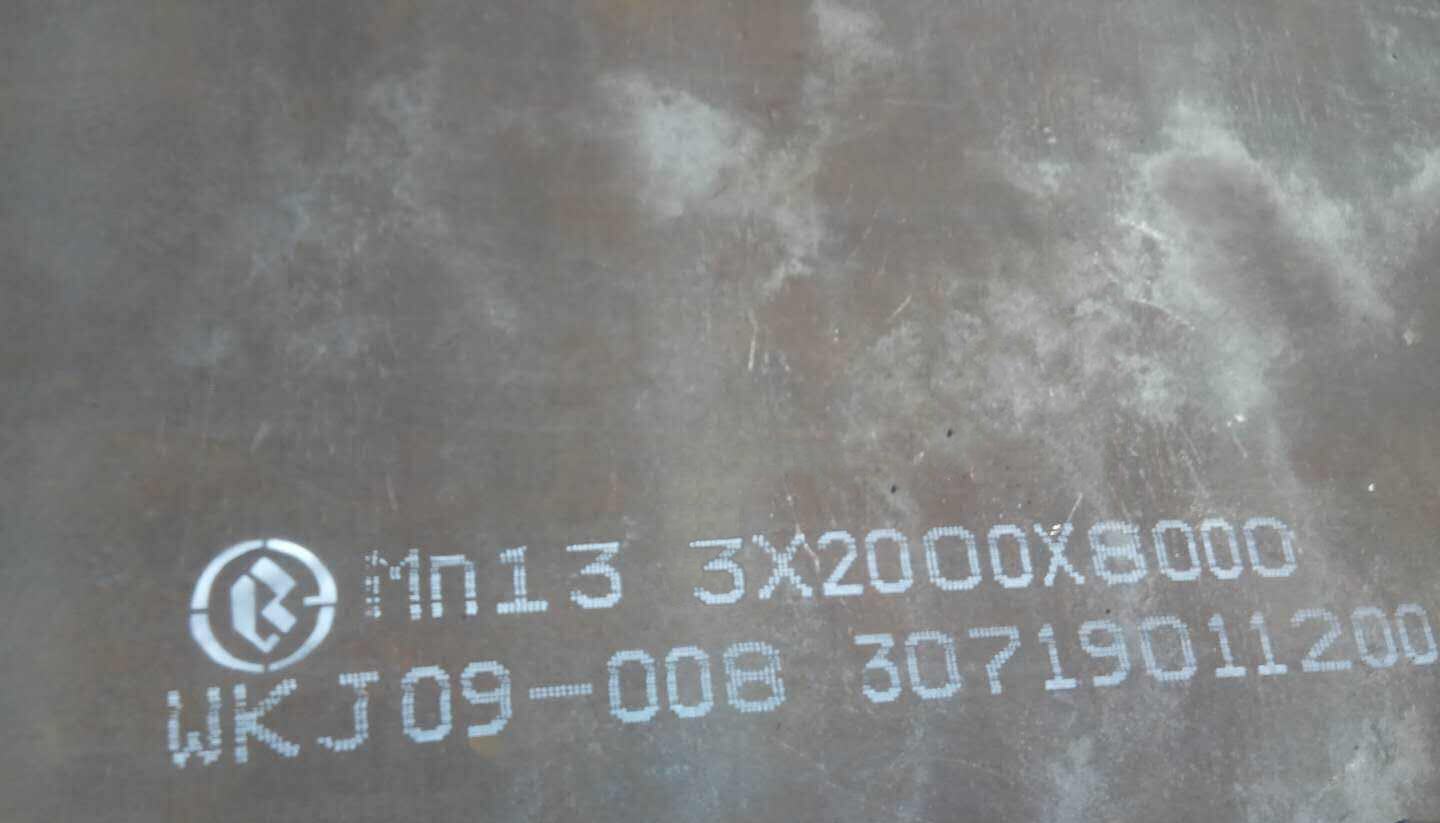

Especificacións:

Especificacións:

|

Artigo |

Mn13 |

|

Ancho |

1000 ata 3000mm |

|

Calidade Estándar |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400,; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

Proceso tecnolóxico |

rolamento controlado, rolamento a calor, normalización, revenido, recocido, temple, N+T, Q+T |

|

Grosor |

2 ata 300mm |

|

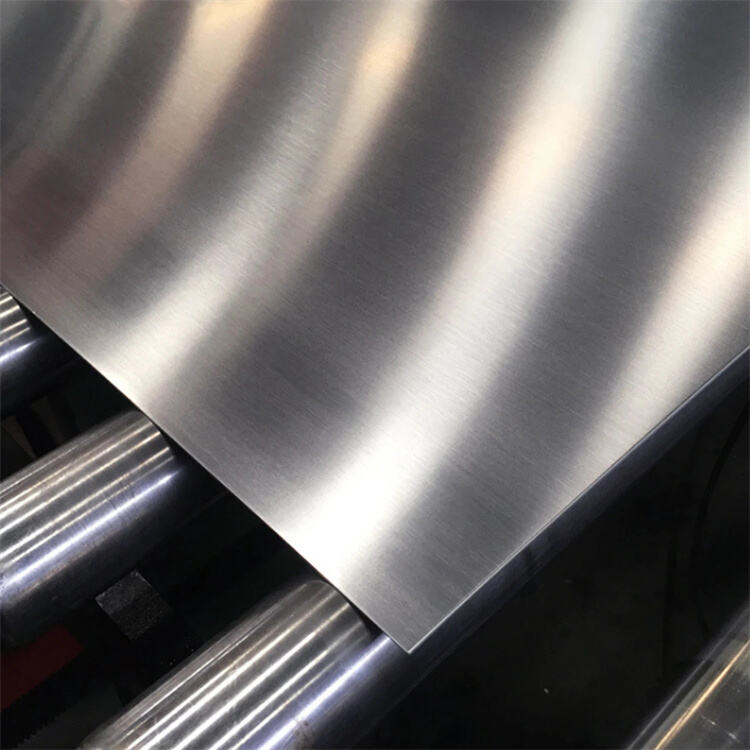

Superficie |

limpeza, chorro de abrasivos, acabado e pintura |

|

Longitude |

1000 ata 12000mm |

Grados Equivalentes de Mn13 :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Composición química do Mn13:

|

Grado |

C |

Si |

Mn |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11,0~14,0 |

≤0.035 |

≤0.030 |

Propiedade mecánica de Mn13:

|

Grado |

Forza de tracción(Mpa) |

Lonxitude (%) |

Rendemento de impacto (20℃) |

Valor inicial de dureza (HB) |

Valor de dureza despois do enduro (HB) |

Dobrado frío (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90 (J) |

200-250 |

>300 |

Cualificado |

Aplicacións:

Aplicacións:

Mn13 a menudo se utiliza para fabricar dentes de pás de excavadoras, muro rodante e muro triturador de trituradoras cónicas, chapa de bateas de trituradoras de mandíbulas, chapas de revestimento de moínos de bolas, desvios ferroviarios, martelos de chapa, cabezas de martelo, etc.

Embalo do Produto:

Embalo do Produto:

Utilizamos os métodos máis seguros e efectivos de embalaxe para todos os tipos de envíos.

FAQ:

FAQ:

1.Q: ¿Canto tempo leva a entrega?

A: Para produtos en stock, faremos envíos en 5-7 días despois de recibir o depósito; para produtos que requiren nova produción para materiais comúns, normalmente se fan envíos en 10-15 días; para produtos que requiren nova produción para materiais especiais e escasos, normalmente son necesarios 20-30 días para facer o envío.

2.Q: ¿Podo visitar a túa fábrica?

A: Claro, benvido a visitar a nosa fábrica en calquera momento.

3.Q: ¿Onde estás?

A: Anyang na provincia de Henan.

4.Q: Que certificacións teñen os vostros produtos?

A: Teñemos ISO 9001, BV, SGS, CE, TUV e outras certificacións.

5.Q:Cal son as condicións de pago?

A: 30% depósito por T/T antecipado, 70% saldo por T/T dentro de 5 días despois do B/L copia, 100%. L/C irrevocable a la vista, 100% L/C irrevocable despois de recibir o B/L 30-120 días, O/A.

Etiqueta:

Mn13, Fabricantes Chineses de Acero de Alto Mn Resistente ao Desgaste, Proveedores, Fábrica, Acero Resistente á Corrosión e ao Desgaste, Acero Endurecido e Temperado de Alta Clase Resistente ao Desgaste, Acero Resistente ao Desgaste con Alta Ductilidade e Arresto de Fracturas Frágeis, Acero Super Resistente ao Desgaste, Acero Resistente ao Desgaste e a Temperaturas Altas, Acero de Alto Mn Resistente ao Desgaste, Acero Resistente ao Desgaste con Baixa Relación de Rendemento