What Is Galvanized Steel?

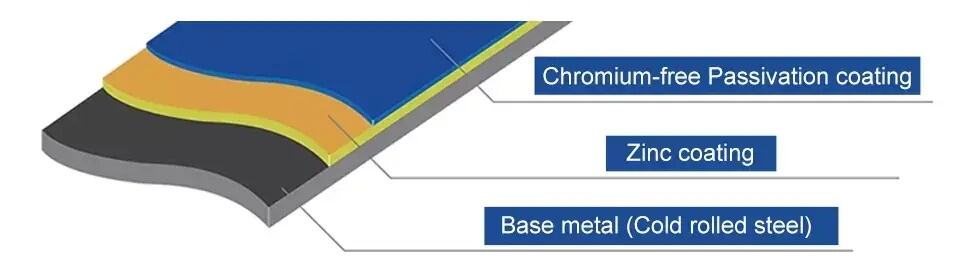

Galvanized steel is a metal material that covers the surface of ordinary steel with a layer of zinc. Its main purpose is to improve the corrosion resistance of steel and thus extend its service life. Steel itself is easily affected by oxygen and moisture and rusts, while zinc has a strong antioxidant ability and can effectively prevent steel corrosion.

Hot Dip Galvanizing Process:

Hot-dip galvanizing is a common galvanizing method. It forms a dense zinc coating on the surface of steel by immersing it in high-temperature molten zinc liquid to enhance corrosion resistance. The hot-dip galvanized layer has strong adhesion, uniform coverage, and can effectively protect the substrate from corrosion.

What Is Stainless Steel?

Stainless steel is a chromium-containing alloy steel with excellent corrosion resistance and mechanical properties. The characteristic of stainless steel is that a certain amount of chromium (Cr) is added to the steel to form a dense chromium oxide (Cr₂O₃) passivation film on its surface, thereby preventing oxygen, moisture and other corrosive media from corroding the steel. In addition to chromium, stainless steel usually contains nickel (Ni), molybdenum (Mo), titanium (Ti), cobalt (Co), manganese (Mn) and other elements to further enhance its corrosion resistance, strength and processing performance.

What Is The Difference Between Galvanized Steel And Stainless Steel?

Stainless Steel Coil Vs. Galvanized Steel Coil

1. Basic Difference

Galvanized steel is a composite material formed by ordinary carbon steel after galvanizing. Its interior is still ordinary steel, but the surface is covered with a layer of zinc to provide a certain degree of corrosion resistance. The main galvanizing methods include hot-dip galvanizing, electrogalvanizing and mechanical galvanizing.

Stainless steel is a chromium-containing alloy steel, usually containing at least 10.5% chromium (Cr), and may be added with nickel (Ni), molybdenum (Mo) and other elements. These alloy elements make stainless steel inherently corrosion-resistant without the need for additional coating protection. According to the different metallographic structures, stainless steel can be divided into several categories such as austenite, ferrite, martensite, duplex and precipitation hardening stainless steel.

2. Corrosion Resistance

The corrosion resistance of galvanized steel mainly relies on the protection of the zinc layer. When the zinc layer is intact, it can effectively prevent the internal steel from being oxidized. However, over time, the zinc layer may gradually disappear due to wear, scratches or chemical reactions, and once the internal carbon steel is exposed, it will begin to rust. Galvanized steel has poor durability in humid, high-salt environments (such as the seaside) or acid-base environments, and requires regular maintenance and replacement.

In contrast, stainless steel forms a dense chromium oxide passivation film on the surface due to the particularity of its own material composition. Even if the surface is slightly damaged, this protective film can automatically repair and continue to provide corrosion protection. This allows stainless steel to maintain stable corrosion resistance in harsh environments (such as high temperature, high humidity, acid-base environment), especially stainless steel materials such as 304 and 316, which perform well in food processing, chemical industry, and marine environments.

3. Cost

Galvanized steel is much cheaper than stainless steel.

The manufacturing cost of galvanized steel is low because its main component is ordinary carbon steel, which is only galvanized on the surface, so the price is relatively economical.

Stainless steel has a high production cost due to the presence of precious metal elements such as chromium and nickel, and its price is usually several times or even more than ten times more expensive than galvanized steel. For example, the market price of ordinary hot-dip galvanized steel sheets may be only one-third or less of 304 stainless steel, while 316 stainless steel is more expensive due to its higher nickel and molybdenum content.

4. Appearance

The surface of galvanized steel is usually silvery white or gray, and there may be some zinc flowers or uneven textures due to different galvanizing processes. Galvanized steel is easily scratched during use, and once the zinc layer is damaged, the exposed substrate is prone to corrosion.

Stainless steel has a metallic luster and can be processed by polishing, brushing, electroplating and other processes to give it a mirror or matte effect.

5. Application

Galvanized steel and stainless steel have different applications in various industries due to their different characteristics.

- Application of galvanized steel:

Building structure: used for roofs, steel structure frames, guardrails, scaffolding, etc.

Building structure: used for roofs, steel structure frames, guardrails, scaffolding, etc.

Traffic facilities: used for highway guardrails, telephone poles, traffic signs, etc.

Traffic facilities: used for highway guardrails, telephone poles, traffic signs, etc.

Home appliance industry: such as refrigerator back panel, air conditioner housing, washing machine housing, etc.

Home appliance industry: such as refrigerator back panel, air conditioner housing, washing machine housing, etc.

Agriculture and animal husbandry: used for barns, fences, greenhouse brackets, etc.

Agriculture and animal husbandry: used for barns, fences, greenhouse brackets, etc.

- Applications of stainless steel:

Food processing: making food-grade containers, kitchen utensils, tableware, food delivery pipelines, etc.

Food processing: making food-grade containers, kitchen utensils, tableware, food delivery pipelines, etc.

Medical industry: manufacturing scalpels, implants, disinfection equipment, etc.

Medical industry: manufacturing scalpels, implants, disinfection equipment, etc.

Chemical and energy: used in refineries, chemical equipment, nuclear power plants, etc.

Chemical and energy: used in refineries, chemical equipment, nuclear power plants, etc.

Marine and aviation: suitable for environments with extremely high corrosion resistance requirements such as ships, submarines, and aircraft engines.

Marine and aviation: suitable for environments with extremely high corrosion resistance requirements such as ships, submarines, and aircraft engines.

Which Is Stronger, Galvanized Steel Or Stainless Steel?

When the thickness and form are similar, stainless steel is always stronger than galvanized steel.

Which Is Better, Galvanized Steel Or Stainless Steel?

Both galvanized steel and stainless steel are widely used. But the one that suits your project is better. Generally speaking, galvanized steel is more economical, while stainless steel is more durable, stronger, and more corrosion-resistant than galvanized steel. You need to choose the material based on the purpose of use, the environment in which it is used, and your budget.

We are a professional steel manufacturer. If you have any needs, you can contact us at any time!

+86 17611015797 (WhatsApp )

+86 17611015797 (WhatsApp )  info@steelgroups.com

info@steelgroups.com