- Ülevaade

- Seotud tooted

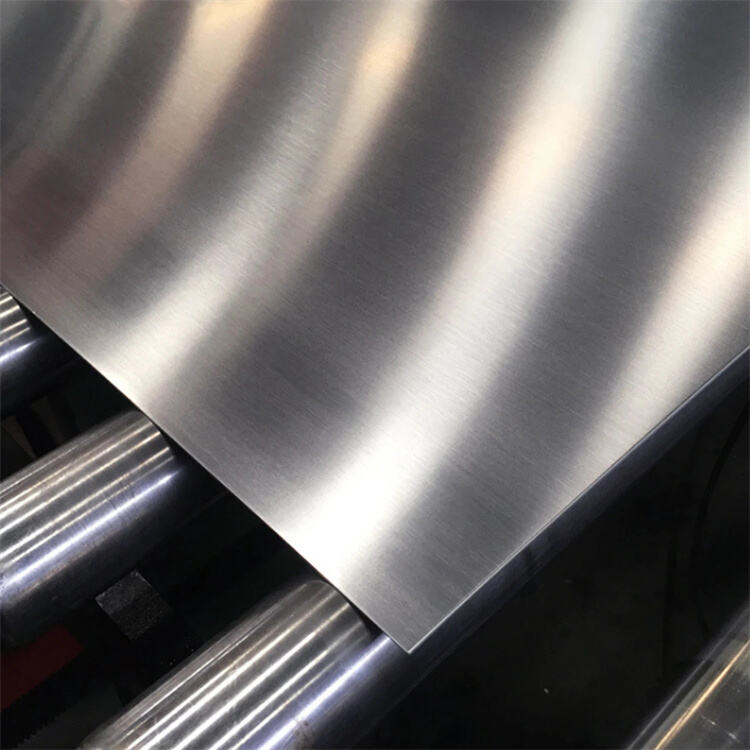

Kirjeldus:

Kirjeldus:

Sümbol "NM" tootes NM600 viitab ausu vastuvõtlikule plaatil, mis on moodustatud sõnade "Nai" ja "Mo" esitähtedest, ning 600 tähistab Brinelli kõvuse väärtust HB. See tase on kõrgem kui NM500, NM450, NM400 ja NM360.

NM600 rakendusstandard: rakendab ettevõtte standardit Q/XGJ166-2009

Toimetamise staatus: külmistamine ja temperdamine (külmistamine + temperdamine)

Spetsifikatsioonid:

Spetsifikatsioonid:

|

Toote nimi |

Kulumitteline Teravplaat |

|

Teraast kvaliteet |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Paksus |

2mm-300mm |

|

Laius |

500-2500mm |

|

Pikkus |

1000mm-12000mm või kliendi eriline nõue |

|

Tolerants |

Paksus: +\/-0,02mm, Laius: +\/-2mm |

|

Kohaletoimetamise aeg |

7-15 töötajat päeva pärast 30% allmäärde saamist |

|

Sertifikaat |

BV SGS CE TUV |

|

Pakend |

Pakenditud terase lõiguga, konteineri saatmine |

NM600 Teravi Standardi Võrdlus:

|

Teraast kvaliteet |

SSAB |

ThyssenKrupp |

JFE |

DILLIDUR |

Ruukki |

|

Nm600 |

HARDOX600 |

XAR600 |

- |

600V |

Raex600 |

NM600 Kulumuse vastane teraplaat Keemilise elemendi koostis (%)

|

Komponent |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

B |

Al |

|

Minimaalne väärtus |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Maksimaalne väärtus |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

NM600 Kulumus Vastupanuline teraplaadi mehaanilised omadused:

|

Paksus |

Lahutusjõud |

Pikkuse muutumine või venimisprotsent |

Kõvadus |

|

t≤60 |

- |

- |

Pindliigusus: 570~640HBW |

NM600 eelised:

Kõrge ausuure tõkevastupidavus: Seesekompoosiisioos on ligikaudu 4-5% süsinikust ja kroomi sisaldus on kuni 25-30%. Metalluurilises struktuuris jõudab Cr7C3 karbidi ruumala osakaal üle 50%, makroliigusus on HRC56-62, ning kroomikarbidi liigusus on HV1400-1800. Kuna karbidid paiknevad ausuure suunas vertikaalselt, siis isegi võrreldes samade koostisosade ja liigususega kaestega, on ausuure tõkevastupidavus rohkem kui kaheks.

Kõrge ausuure tõkevastupidavus: Seesekompoosiisioos on ligikaudu 4-5% süsinikust ja kroomi sisaldus on kuni 25-30%. Metalluurilises struktuuris jõudab Cr7C3 karbidi ruumala osakaal üle 50%, makroliigusus on HRC56-62, ning kroomikarbidi liigusus on HV1400-1800. Kuna karbidid paiknevad ausuure suunas vertikaalselt, siis isegi võrreldes samade koostisosade ja liigususega kaestega, on ausuure tõkevastupidavus rohkem kui kaheks.

Hea mõjuvastus: Kulumatasteelsete liitplaatide aluseks on tugev materjal, nagu madalvooleline või madallegendoitud teras, mis väljendab bimetaali eelisega. Kulumatase kiht vastab kulumaterjalile ja aluskiht kannatab materjali koormust, seetõttu on sellel hea mõjuvastus. See suudab tervestada kõrge langemiskaugusega ladude impulsi ja kulut.

Hea mõjuvastus: Kulumatasteelsete liitplaatide aluseks on tugev materjal, nagu madalvooleline või madallegendoitud teras, mis väljendab bimetaali eelisega. Kulumatase kiht vastab kulumaterjalile ja aluskiht kannatab materjali koormust, seetõttu on sellel hea mõjuvastus. See suudab tervestada kõrge langemiskaugusega ladude impulsi ja kulut.

Hea lämmushaltaegsus: ligipääsetav on kasutada ≤600 töötingimustes. Kui vanadiini, molibdaani ja teiste ligipääsetavate kihtide lisatakse ligipääsetava kihti, võib see vastupidavalt kannatada ≤800 kõrgelähmusega. Soovitatakse järgmist töötamistemperatuuri: Tavalise süsiniku terase alused soovitatakse kasutada töötingimustes, mis ei ületa 380; Madal ligipäästev lähmuseterassiplaadid (15CrMo, 12Cr1MOV jne) alused soovitatakse kasutada töötingimustes, mis ei ületa 540; Lähmustega vastuoluline roosteta terase alused soovitatakse kasutada töötingimustes, mis ei ületa 800.

Hea lämmushaltaegsus: ligipääsetav on kasutada ≤600 töötingimustes. Kui vanadiini, molibdaani ja teiste ligipääsetavate kihtide lisatakse ligipääsetava kihti, võib see vastupidavalt kannatada ≤800 kõrgelähmusega. Soovitatakse järgmist töötamistemperatuuri: Tavalise süsiniku terase alused soovitatakse kasutada töötingimustes, mis ei ületa 380; Madal ligipäästev lähmuseterassiplaadid (15CrMo, 12Cr1MOV jne) alused soovitatakse kasutada töötingimustes, mis ei ületa 540; Lähmustega vastuoluline roosteta terase alused soovitatakse kasutada töötingimustes, mis ei ületa 800.

Rakendused:

Rakendused:

NM600 leidis laialdase rakenduse metallurgias, köögikivi, tsement, elekter, klaas, kaevandus, ehitusmaterjalid, muurikivid ja muudes tööstusharudes.

Toote pakendamine:

Toote pakendamine:

Me kasutame kõigi liikmete jaoks pakendamiseks kõige turvalisemat ja kõige tõhusamat viisi.

KKK:

KKK:

1.Q: Kui kaua toodete saatmine võtab aega?

V: Varudega toodete puhul saadetakse tellimus 5–7 päeva jooksul pärast ettemaksu vastuvõtmist; tavaliste materjalidega uute toodete puhul saadetakse tellimus tavaliselt 10–15 päeva jooksul; eriliste ja haruldaste materjalidega uute toodete puhul võtab saatmine tavaliselt 20–30 päeva.

2.Q: Võin ma teie tehas külastada?

V: Mäletage, olete alati teretulnud külastama meie tehas igal ajal.

3.Q: Kus te asutate?

V: Henan provintsi Anyangis.

4.Q: Millised sertifikaadid on teie toodete juures?

A: Meil on ISO 9001, BV, SGS, CE, TUV ja muud sertifikaadid.

5.Q: Mis on teie maksetingimused?

A: 30% T/T eelneva depo, 70% T/T jääk 5 päeva pärast B/L koopia, 100%. Mittevõetav L/C silma ette, 100% mittevõetav L/C pärast B/L saamist 30-120 päeva, O/A.

Silt:

NM600, Hiina ausuuse vastane tera lehtede tootjad, pakkujad, tehas, NM300 ausuuse vastane tera leht, NM360 ausuuse vastane tera leht, NM500 ausuuse vastane tera leht, Kõrge ausuuse ja kõrge jõudlusega, Kõrge kvaliteediga, NM600 ausuuse vastane tera plaat ,NM300TP ,NM400 ,NM400E ,Nm450 ,NM450E ,Nm500 ,NM500E