- Oversigt

- Relaterede produkter

Beskrivelse:

Beskrivelse:

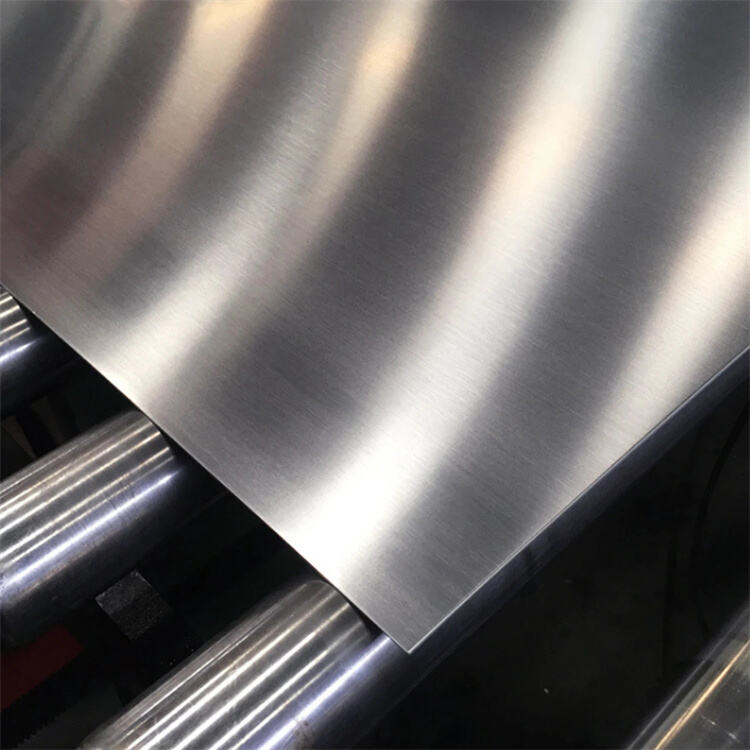

Det "NM" i NM600 henviser til slipresistent plade, de første bogstaver i "Nai" og "Mo", og 600 er Brinell-hårdheds-værdien (HB-værdi). Graden er højere end NM500, NM450, NM400 og NM360.

NM600 implementeringsstandard: implementer virksomhedskrav Q/XGJ166-2009

Leveringsstatus: kvælstofbehandling og temperering (kvælstofbehandling + temperering)

Specifikationer:

Specifikationer:

|

Produktnavn |

Slipbestandig Stålplade |

|

Stålstyrke |

NM300,NM300TP,NM360, NM400, NM400E,NM450,NM450E, NM500, NM550, NM500E,NM600 |

|

Standard |

GB, ASTM, JIS ,DIN, ASTM |

|

Tykkelse |

2mm-300mm |

|

Bredde |

500-2500mm |

|

Længde |

1000mm-12000mm eller efter kundens særlige anmodning |

|

Tolerancen |

Tjukke: +\/–0,02 mm, Bredde: +\/–2 mm |

|

Leveringstid |

7-15 arbejdsdage efter modtagelse af 30% afgift |

|

Certifikat |

BV SGS CE TUV |

|

Pakke |

Bundling med stålremme, Containerfrakt |

NM600 Stål Standard Sammenligning:

|

Stålstyrke |

SSAB |

ThyssenKrupp |

JFE |

DILLIDUR |

Ruukki |

|

Nm600 |

HARDOX600 |

XAR600 |

- |

600 V |

Raex600 |

NM600 Skurværkstyrke Stålplade Kemisk Element Sammensætningsindhold (%)

|

Komponent |

C |

Ja |

Mn |

P |

S |

Kr |

Ni |

- Hvad? |

Ti |

B |

AL |

|

Minimumsværdi |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0005 |

0.01 |

|

Maksimal værdi |

0.45 |

0.7 |

1.9 |

0.02 |

0.01 |

1.6 |

2 |

0.8 |

0.05 |

0.006 |

- |

NM600 Slip Modstandsdygtig Stålplade Maskintekniske Egenskaber:

|

Tykkelse |

Trækfasthed |

Stregning eller Udstedelsesrate |

Hårdhed |

|

t≤60 |

- |

- |

Overfladehardhed: 570~640HBW |

Fordele ved NM600:

Høj slipbestandighed: Karbonindholdet i den kemiske sammensætning af den legetøjsslipbestandige lag er 4-5%, og chromeindholdet når op til 25-30%. Volumefractionen af Cr7C3 karbid i dets metallografiske struktur når over 50%, makrohardheden er HRC56-62, og hardheden af chrome karbid er HV1400-1800. Fordi karbidene er fordelt vinkelret på slipretningen, er slipbestandigheden endda dobbelt så høj sammenlignet med kastingsalloyer med det samme indhold og hardhed.

Høj slipbestandighed: Karbonindholdet i den kemiske sammensætning af den legetøjsslipbestandige lag er 4-5%, og chromeindholdet når op til 25-30%. Volumefractionen af Cr7C3 karbid i dets metallografiske struktur når over 50%, makrohardheden er HRC56-62, og hardheden af chrome karbid er HV1400-1800. Fordi karbidene er fordelt vinkelret på slipretningen, er slipbestandigheden endda dobbelt så høj sammenlignet med kastingsalloyer med det samme indhold og hardhed.

God modstandsdygtighed mod impakten: Substratet i den skadesikre kompositstålplade er et tøft materiale som lavkarbonstål eller lavlegeme, hvilket viser fordelen ved bimetal. Skadesikkerlagslaget modstår skaden forårsaget af det skadesikrende medium, mens substratet bærer lasten af mediumet, således at det har en god modstandsdygtighed mod impakten. Det kan klare impakten og skaden fra højfaldende hopper i materialtransportsystemer.

God modstandsdygtighed mod impakten: Substratet i den skadesikre kompositstålplade er et tøft materiale som lavkarbonstål eller lavlegeme, hvilket viser fordelen ved bimetal. Skadesikkerlagslaget modstår skaden forårsaget af det skadesikrende medium, mens substratet bærer lasten af mediumet, således at det har en god modstandsdygtighed mod impakten. Det kan klare impakten og skaden fra højfaldende hopper i materialtransportsystemer.

God varmebestandighed: Det anbefales, at den alloy-bæringslag bruges under ≤600 arbejdsforhold. Hvis vanadium, molybdenum og andre alloy tilføjes til den alloy-bæringslag, kan det klare højtemperaturskade på ≤800. Den anbefalede driftstemperatur er følgende: Almindelige kulstofstål baser anbefales brugt under arbejdsforhold, der ikke overstiger 380; Lav alloy-varmebestandig stålblad (15CrMo, 12Cr1MOV osv.) baser anbefales brugt under arbejdsforhold, der ikke overstiger 540; Højtemperatursstainless stål baser anbefales brugt under arbejdsforhold, der ikke overstiger 800.

God varmebestandighed: Det anbefales, at den alloy-bæringslag bruges under ≤600 arbejdsforhold. Hvis vanadium, molybdenum og andre alloy tilføjes til den alloy-bæringslag, kan det klare højtemperaturskade på ≤800. Den anbefalede driftstemperatur er følgende: Almindelige kulstofstål baser anbefales brugt under arbejdsforhold, der ikke overstiger 380; Lav alloy-varmebestandig stålblad (15CrMo, 12Cr1MOV osv.) baser anbefales brugt under arbejdsforhold, der ikke overstiger 540; Højtemperatursstainless stål baser anbefales brugt under arbejdsforhold, der ikke overstiger 800.

Anvendelser:

Anvendelser:

NM600 findes i bred anvendelse inden for metallurgi, kul, cement, elektricitet, glas, mining, bygge materialer, tegl og andet industrier.

Produktforpaking:

Produktforpaking:

Vi bruger de sikreste og mest effektive emballageformer for alle typer af leverancer.

OFTE STILTE SPØRGSMÅL:

OFTE STILTE SPØRGSMÅL:

1.Q: Hvor længe tager det at levere?

A: For lagerprodukter vil vi sende fragt inden for 5-7 dage efter modtagelse af depositum; for produkter der kræver ny produktion af almindelige materialer, sender vi normalt fragt inden for 10-15 dage; for produkter der kræver ny produktion af specielle og sjældne materialer, tager det normalt 20-30 dage at sende fragt.

2.Q:Kan jeg besøge din fabrik?

A: Selvfølgelig, velkommen til at besøge vores fabrik når som helst.

3.Q:Hvor er du?

A:Anyang i provinsen Henan.

4.Q: Hvad for certifikater har dine produkter?

A: Vi har ISO 9001, BV, SGS, CE, TUV og andre certifikater.

5.Q:Hvad er dine betalingsbetingelser?

A:30% T/T indbetaling i forvejen, 70% T/T resten inden for 5 dage efter modtagelse af B/L kopi, 100%. Uigenkaldelig L/C ved første visning, 100% uigenkaldelig L/C efter modtagelse af B/L 30-120 dage, O/A.

Tag:

NM600, Kina Modstandsdygtig Stålplade producenter, leverandører, fabrik, NM300Modstandsdygtig Stålplade, NM360Modstandsdygtig Stålplade, NM500Modstandsdygtig Stålplade, Høj modstand og høj tøghed, Høj kvalitet, NM600 Trælsmodstandsdygtig Stålplade ,NM300TP ,NM400 ,NM400E ,Nm450 ,NM450E ,Nm500 ,NM500E