- Visió general

- Productes relacionats

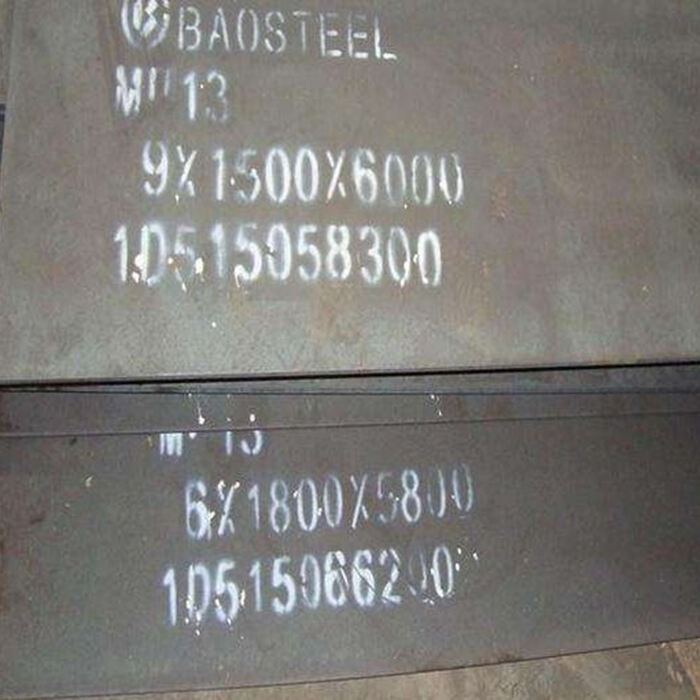

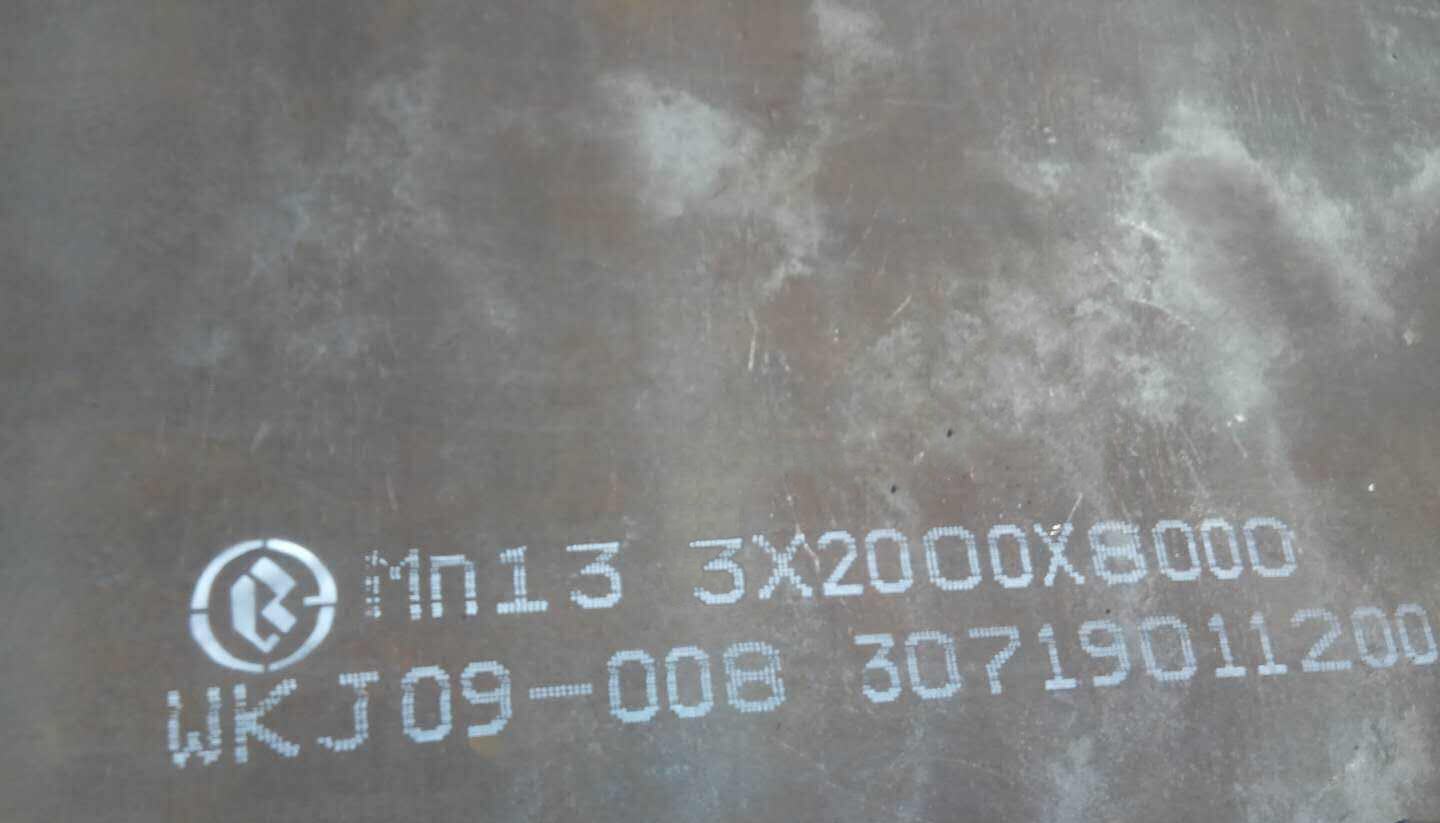

Descripció:

Descripció:

El Mn13 és l'elecció dels materials antidesgast que poden resistir impactes forts, desgast de materials sota alta pressió, etc. Té característiques d'endurciment per treball que altres materials antidesgast no poden igualar. Sota l'acció d'una càrrega d'impacte gran o d'un estress de contacte gran, la superfície de la placa d'acer es durça per treball, i la duresa de la superfície passa ràpidament de HB200 a més de HB500, produeint una capa superficial altament antidesgast, mentre que l'austenita interna de la placa d'acer segueix mantenint una bona resistència als impactes.

Hi ha dues característiques d'acer de manganes alt:

1. Quan major sigui la càrrega d'impacte extern, més alta serà la resistència al desgast de la seva capa superficial;

2. A mesura que la capa endurida gradualment es desgasta, es formarà continuament una nova capa d'endurciment per treball.

Les propietats especials de l'acer d'alt manganese són adequades per a la fabricació de components resistents al desgast que suporten el desgast a llarg termini de materials d'impacte alt. Fa molt que s'utilitza ampliament en equipaments mecànics com ara metallurgia, mineria, materials de construcció, ferrocarrils, electricitat i carbó.

Especificacions:

Especificacions:

|

Article |

Mn13 |

|

AMPLADA |

1000 fins a 3000mm |

|

Grau Estàndard |

DIN:1.3401, XAR400, XAR300, XAR450, XAR600, XAR500, X120Mn12 EN : QUARD450, QUARD400, QUARD500; RAEX320, RAEX500, RAEX400 NF : FORA500, FORA400,; Creusabro8000, Creusabro4800 GB : NM360, Mn13, NM600, NM400, NM450, NM500, NM550 JIS : JFE-EH400, JFE-EH360, JFE-EH500; WEL-HARD500, WEL-HARD400 |

|

Procés tecnològic |

llançament controlat, calfatjat, normalització, reveniment, anellotge, trempada, N+T, Q+T |

|

Gruix |

2 fins a 300mm |

|

Superfície |

neteja, escombrat, acabat i pintura |

|

Longitud |

1000 fins a 12000mm |

Grades Equivalents de Mn13 :

|

GB |

EN |

ASTM |

AFNOR |

|

Mn13 |

1.3401-X120Mn13 |

A128GrB2 |

X120Mn13 |

Composició Química del Mn13:

|

Grau |

C |

Si |

Mn |

P |

S |

|

Mn13 |

0.90~1.20 |

0.3~0.8 |

11.0~14.0 |

≤0.035 |

≤0.030 |

Propietat mecànica de Mn13:

|

Grau |

Força de tracció (Mpa) |

Allongament (%) |

Rendiment d'impacte (20℃) |

Valor inicial de duresa (HB) |

Valor de duresa després del durament (HB) |

Flectació a fred (180°) |

|

Mn13 |

≥800 |

≥40 |

ak≥90 (J) |

200-250 |

>300 |

Qualificat |

Aplicacions:

Aplicacions:

El Mn13 s'utilitza sovint per fabricar dents de pala d'excavadores, parets rodants i parets esmagadores de trituradores cònics, plaques de mandíbula de trituradores de mandíbula, revestiments de molins de bolas, canvis ferroviaris, martells de placa, capses de martell, etc.

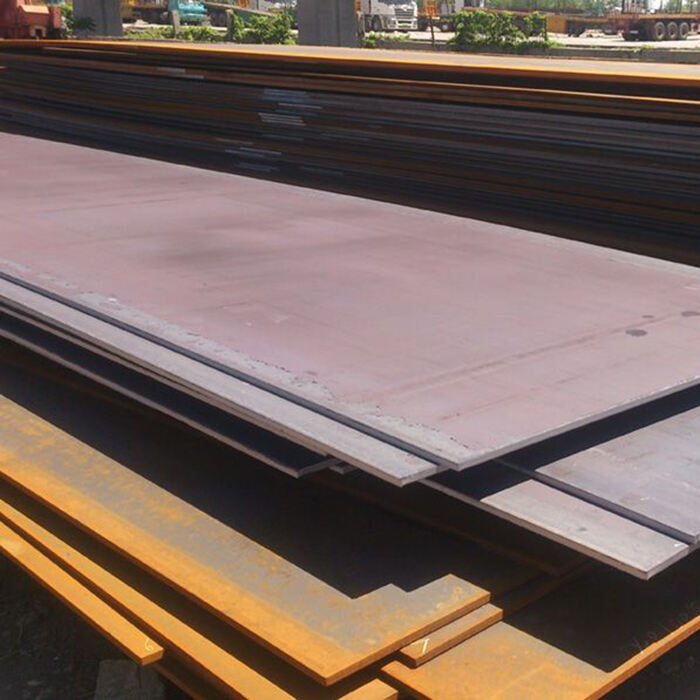

Embalatge del Producte:

Embalatge del Producte:

Utilitzem els mètodes de paquetatge més segurs i efectius per a tots els tipus d'enviaments.

Preguntes freqüents:

Preguntes freqüents:

1.Q: Quan podeu fer la entrega?

A: Per als productes en stock, farem els enviaments en 5-7 dies després de rebre l'abonament; per als productes que necessiten una nova producció de materials comuns, normalment es fan enviaments en 10-15 dies; per als productes que necessiten una nova producció de materials especials i rars, normalment calen 20-30 dies per fer l'enviament.

2.Q: Puc visitar la vostra fàbrica?

A: Segur, us donem la benvinguda per visitar la nostra fàbrica en qualsevol moment.

3.Q: On esteu situats?

A: A Anyang, a la província de Henan.

4.Q: Quines certificacions tenen els vostres productes?

A: Tenim les certificacions ISO 9001, BV, SGS, CE, TUV i altres certificacions.

5.Q:Quines són les vostres condicions de pagament?

A:30% d'anticip de T/T, 70% de saldo de T/T dins de 5 dies després de la còpia del B/L, 100%. L/C irrevocable a vista, 100% L/C irrevocable després de rebre el B/L 30-120 dies, O/A.

Tag:

Mn13, Fabricants Xinesos d'Aci de Mn Alt Resistente al Desgast, Proveïdors, Fàbrica, Aci Resistente a la Corrosió i al Desgast, Aci Endurit i Temperat de Classe Superior Resistente al Desgast, Aci de Alta Ductilitat Resistente a les Fractures Britàniques, Aci Super Resistente al Desgast, Aci Resistente al Desgast i a la Temperatura Alta, Aci de Mn Alt Resistente al Desgast, Aci Resistente al Desgast amb Relació de Cedència Baixa